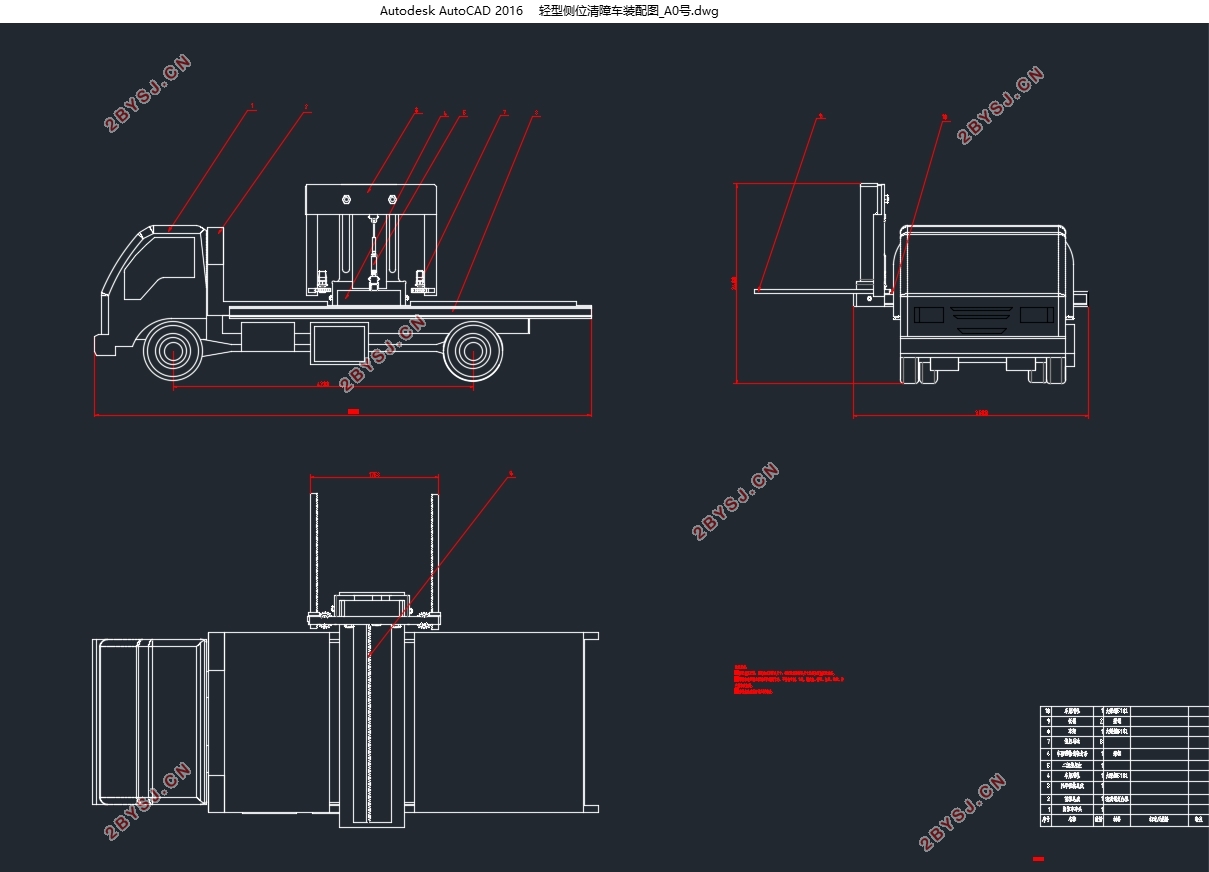

轻型侧位道路清障车总体布置与设计(含CAD图,SolidWorks三维图)(英文版)

无需注册登录,支付后按照提示操作即可获取该资料.

轻型侧位道路清障车总体布置与设计(含CAD图,SolidWorks三维图)(英文版)(任务书,开题报告英文版,外文翻译,论文说明书英文版8000字,CAD图纸5张,SolidWorks三维图)

摘 要

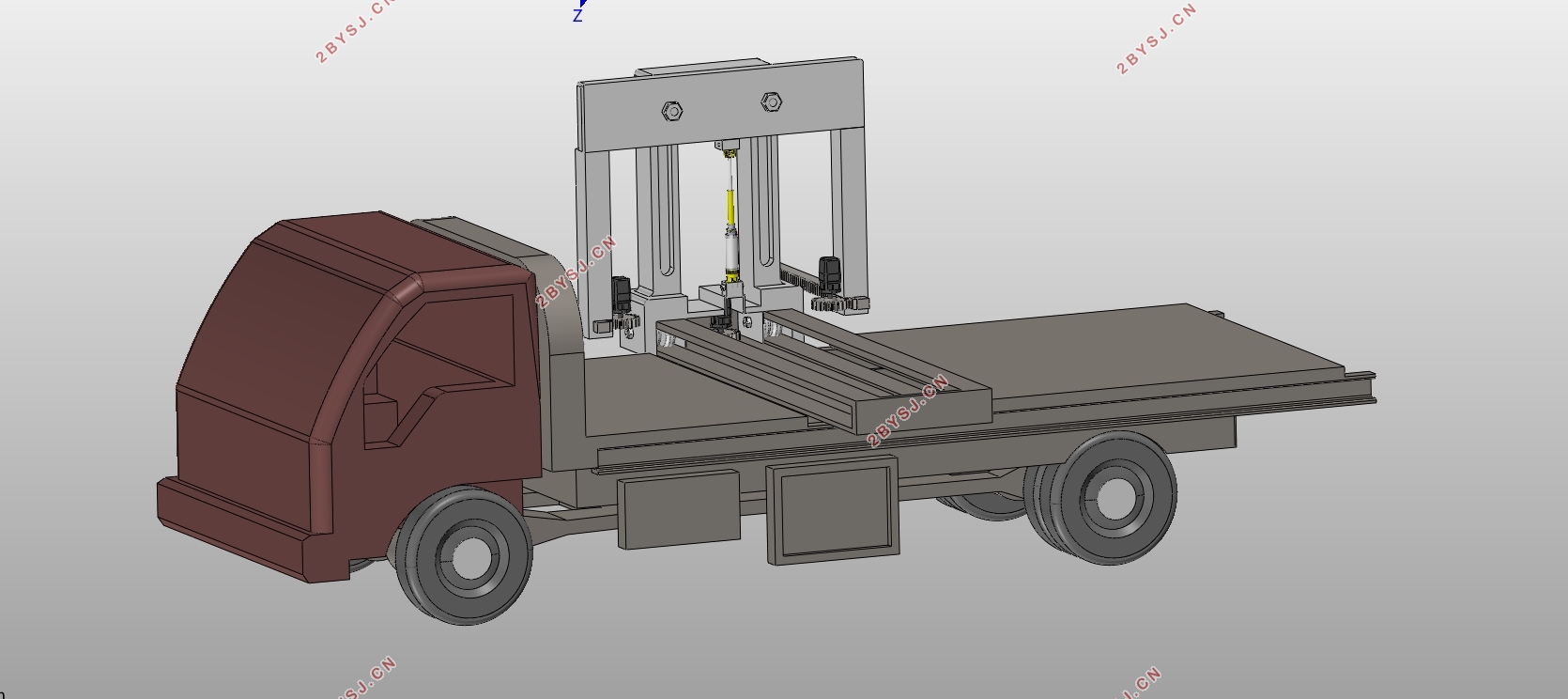

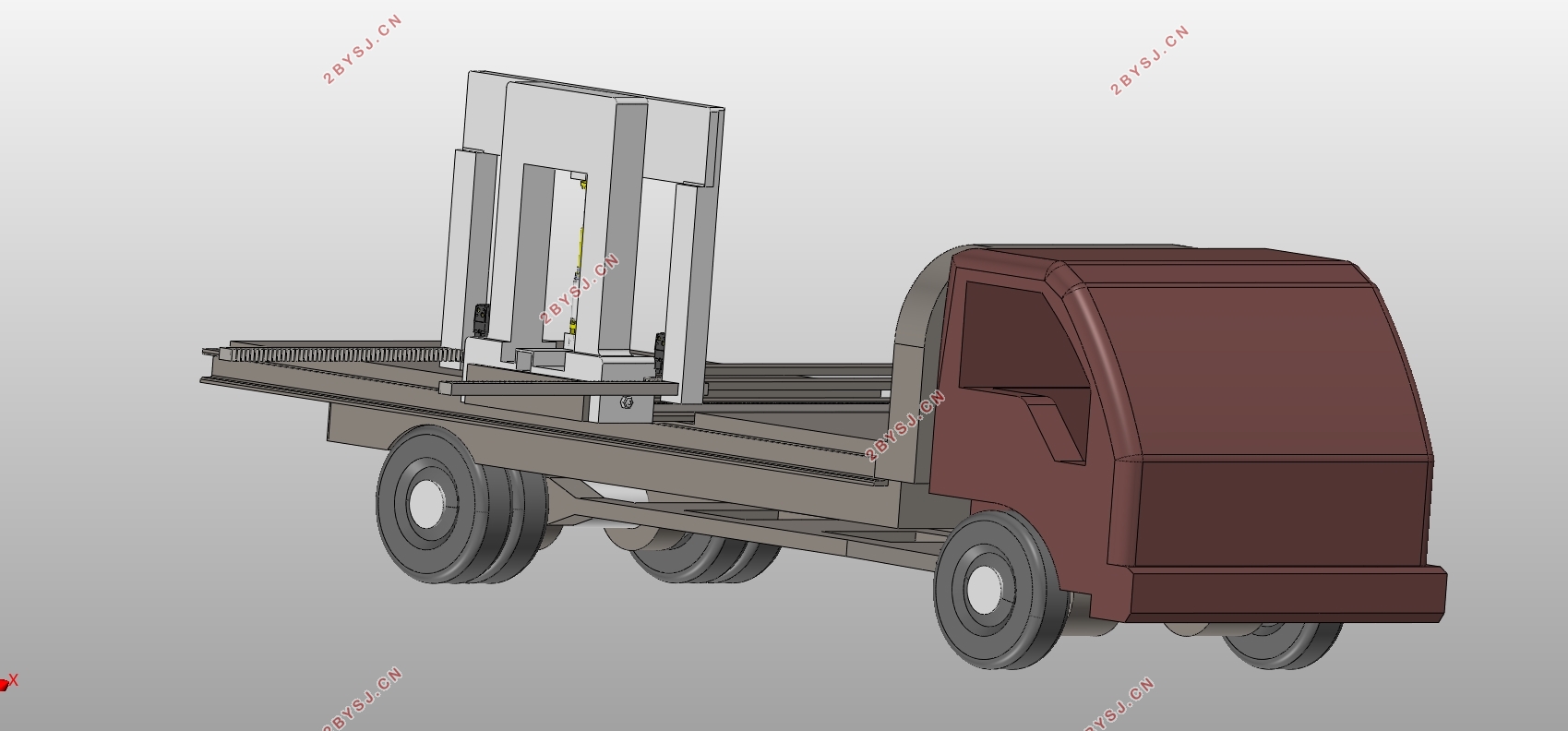

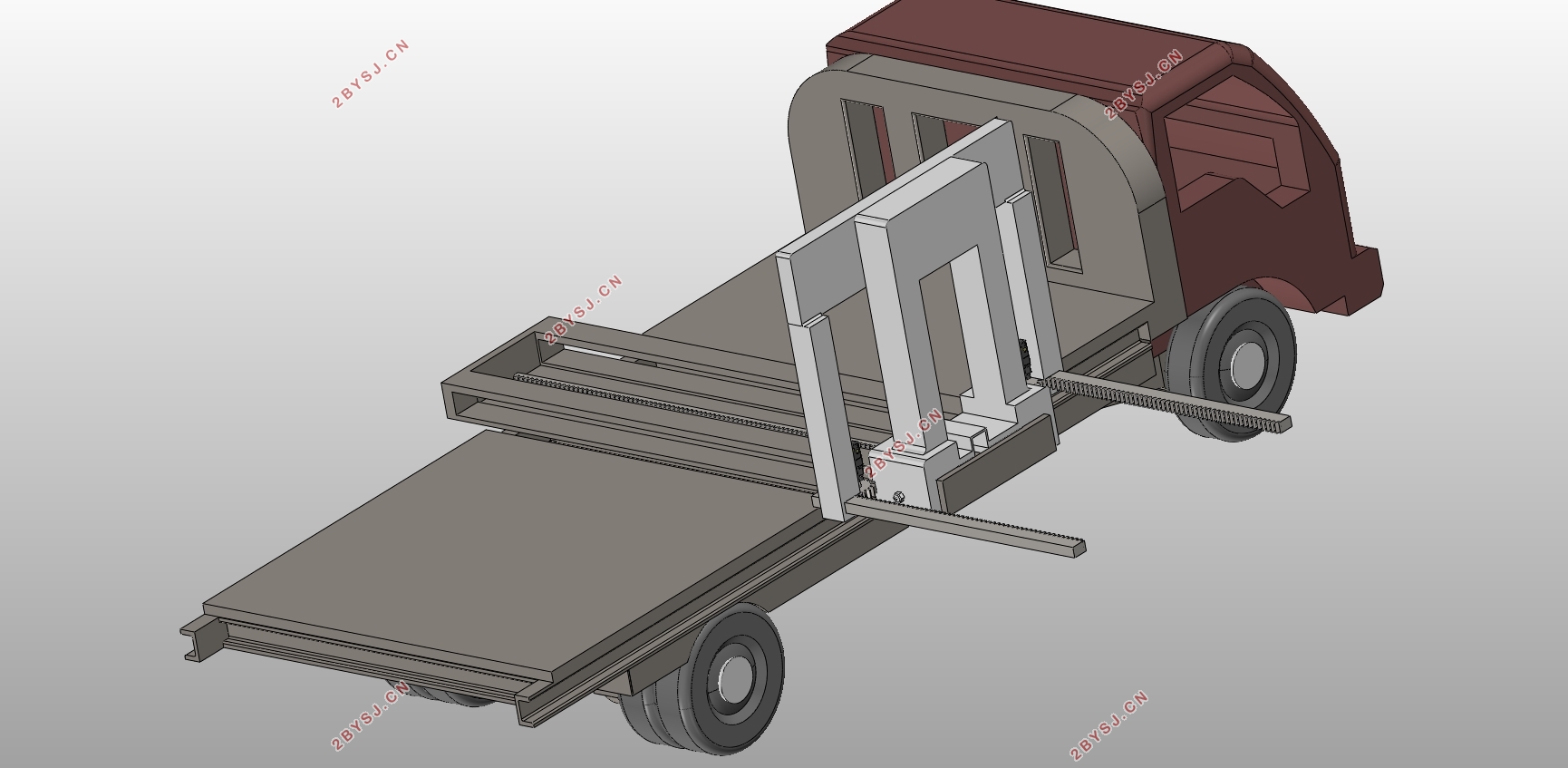

本文运用三维建模软件SolidWorks,首先针对轻型侧位道路清障车进行了方案探讨,进而进行整车建模;同时查阅了相关资料,对此类型清障车的总体布置进行设计,所得结果对于清障车未来的发展方向具有重要的指导意义。

论文主要对这种新型车辆进行了结构方案的设计和总体布置的规划。

研究结果表明:清障车从侧面进行清障具有理论的可行性,基于它相比一般的道路清障车而言更加方便,对场地要求也减小,所以设计这样一种清障车具有重要的研究意义。

本文的特色:本文设计的清障执行机构具有一定的创新性,总体布置与设计也具有良好的可操作性。

关键词:侧位清障车;结构方案;底盘选型;

Abstract

This article takes advantage of the 3D modeling software SolidWorks. First of all, the article discusses the scheme of the light side road wrecker, and then carries on the vehicle modelling, and consults the related materials to design the overall layout of this type of wrecker. The results obtained have important guiding significance for the future development direction of the wrecker.

The dissertation mainly focuses on the design of the structural scheme and the overall layout of the new vehicle.

The results of the study show that the wrecker has theoretical feasibility for removing obstacles from the side. Because it is more convenient than the ordinary road wrecker, and the site requirements are also reduced, so designing it has important research significance.

The characteristics of this article: The design of the obstacle clearing implement has a certain degree of innovation, and the overall layout and design are maneuverable.

Key Words:Side Wrecker; structure design; chassis selection

Table of Contents

Chapter 1 Introduction 1

1.1 Research Background 1

1.2 The aim and meaning of the research 4

Chapter 2 Introduction 5

2.1 Argumentation of the Structural Plan 5

2.1.1 Chassis load quality utilization factor 5

2.1.2 The weight of the special equipment 5

2.2 Select structural scheme 6

2.2.1 Horizontal slide structure scheme 6

2.2.2 Vertical lifting mechanism structure scheme 7

2.2.3 Support arm structure scheme 7

2.2.4 Overall structure plan 8

2.3 Determination of hydraulic control 9

Chapter 3 Wrecker Chassis Selection and Design 11

3.1 The determination of the quality parameters of the wrecker 11

3.1.1 Maintenance quality 11

3.1.2 Total mass 11

3.2 The selection of wrecker engine parameter 11

3.2.1 Maximum engine power and its corresponding speed 11

3.2.2 Maximum engine torque and its corresponding speed 12

3.2.3 Engine adaptability coefficientφ 12

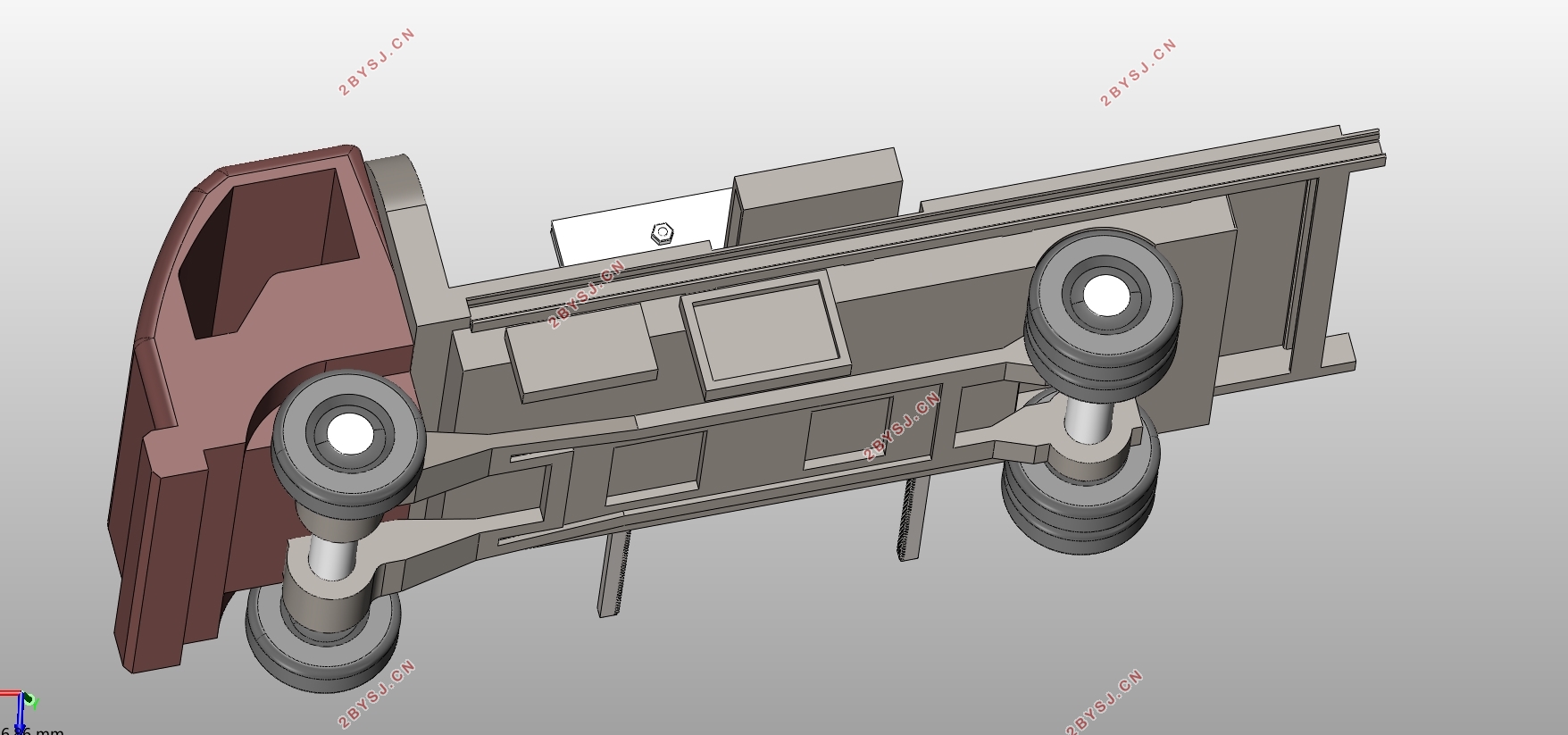

3.3 Related parameters of the chassis 13

3.4 Related calculations of the chassis 14

3.4.1 Conditioning mass and axle load distribution 14

3.4.2 Performance parameters 14

3.4.3 Size parameters 15

Chapter 4 The design of Power take-off 17

4.1 The principle and requirement of power take-off 17

4.2 The selection of power take-off 18

Chapter 5 The design of hydraulic system 22

5.1 The introduction and principle of hydraulic system 22

5.2 Hydraulic cylinder structure design 24

5.3 Hydraulic pump device 25

5.3.1 Hydraulic pump installation 25

5.3.2 The connection of hydraulic pump and motor 26

Chapter 6 Design and calculation of actuator 28

Chapter 7 Conclusion 31

References 32

Express thanks 33