某轻型货车保险杠蒙皮轻量化结构设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

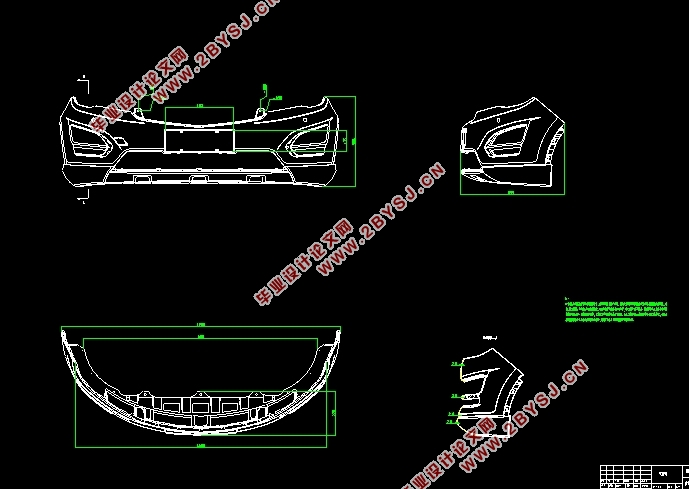

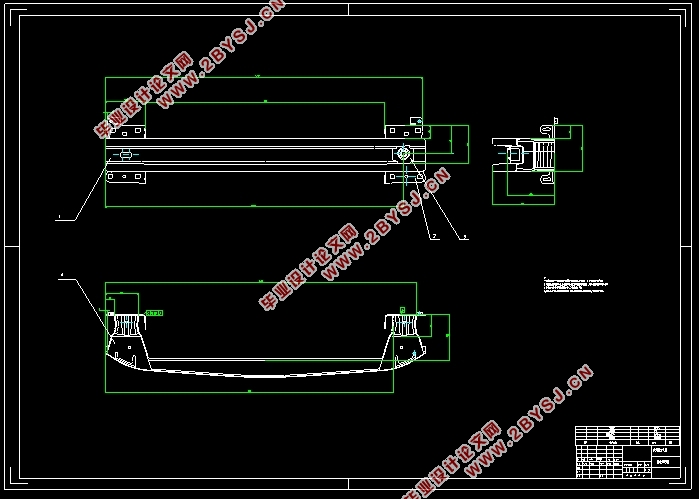

某轻型货车保险杠蒙皮轻量化结构设计(含CAD图)(任务书,开题报告,论文说明书11000字,CAD图纸4张)

摘要

本文借助三维建模软件CATIA V5R20和CAE分析软件ANSYS18.0首先针对某款轻型货车的保险杠蒙皮建立相应的数学分析模型,并且对其进行结构和性能分析,然后根据分析结果和结构与性能的要求对现有的模型进行轻量化结构设计与优化,最后进行性能校核。此次设计针对某轻型货车的保险杠蒙皮实现轻量化的结构设计,有助于进一步理解汽车轻量化的设计理念和较深入了解部分汽车轻量化技术,并且熟悉CAE模型的建立和整个有限元分析对于汽车机械设计的重要作用和意义。同时在实践中初步了解汽车零部件开发的整个流程,实现从理论向实践、从书本向企业的过度,初步培养切合实际、实事求是的思考方式和工作态度。该项目的最终研究设计成果是现代汽车轻量化技术一次有力的探索和实践,是轻量化思想和方法的鲜明拓展,具有较强的创新性。并且从根本上减少了制造用料,在现代化的大规模集成化生产中,有效减少了零件的生产成本,进而减少国民的购买成本,对于汽车销量有显著的推动作用,并且在很大程度上促进汽车行业的经济发展和稳定运营。

此次设计主要以某轻型货车为对象,依据轻型货车保险杠蒙皮性能与设计要求,完成蒙皮子系统模型结构的轻量化设计改善,绘制出设计图纸,并且进行轻量化设计与性能分析。

研究结果表明:对某轻型货车保险杠蒙皮,在满足结构性能和其他相关规定下,适当减小蒙皮子系统的厚度是一个有效的轻量化设计方法,也是其结构优化的一条最有效的途径。

本文的特色:运用CAE仿真模拟分析技术直接对某轻型货车保险杠蒙皮系统进行轻量化结构设计与优化,运用严谨的数据模拟避免了实际操作中的多种问题,快速有效地探索出保险杠蒙皮实现轻量化设计的方法,期间节约了大量的时间和资源,达到了事半功倍的效果。

关键词:轻量化;保险杠;蒙皮子系统;CAE

Abstract

In this paper, the 3D modeling software CATIA V5R20 and CAE analysis software ANSYS18.0 are used to first establish the corresponding mathematical analysis model for the bumper skin of a light truck, and analyze its structure and performance, and then based on the analysis results and structure and performance. The requirements for lightweight design and optimization of existing models, and finally performance checks. The design of the bumper skin of a light truck achieves a lightweight structural design, which helps to further understand the lightweight design concept of the car and better understand some of the car lightweight technology, and is familiar with the establishment of the CAE model and the entire finite element. Analysis of the important role and significance of automotive machinery design. At the same time, in practice, we will initially understand the whole process of auto parts development, realize the transition from theory to practice, from books to enterprises, and initially cultivate practical and practical thinking and work attitude. The final research and design result of this project is a powerful exploration and practice of modern automobile lightweight technology. It is a clear expansion of lightweight ideas and methods, and it has strong innovation. And fundamentally reduce the manufacturing materials, in the modern large-scale integrated production, effectively reduce the production cost of parts, thereby reducing the national purchase cost, has a significant role in promoting car sales, and to a large extent Promote economic development and stable operation of the automotive industry.

This design is mainly for a light truck, based on the performance and design requirements of the light truck bumper skin, complete the lightweight design improvement of the skin subsystem model structure, draw the design drawings, and carry out lightweight design and performance analysis.

The research results show that for a light truck bumper skin, under the structural performance and other relevant regulations, it is an effective lightweight design method to reduce the thickness of the skin subsystem. It is also the most effective way to optimize its structure. .

The characteristics of this paper: Using CAE technology to directly design and optimize the lightweight structure of a light truck bumper skin system, using rigorous data simulation to avoid various problems in actual operation, quickly and effectively explore the realization of bumper skin The lightweight design method saves a lot of time and resources during the period and achieves twice the result with half the effort.

Key Words:lightweight; bumper; fascias subsystem; CAE

主要研究内容与目标

以某款轻型货车为对象,依据轻型货车保险杠蒙皮性能与设计要求,完成蒙皮子系统模型结构的轻量化设计改善,绘制出设计图纸,并且进行轻量化设计与性能分析。具体内容与目标如下:

(1) 分析轻型货车保险杠蒙皮的性能与设计要求;

(2) 依据要求建立保险杠蒙皮的CAE数据分析模型;

(3) 保险杠蒙皮结构性能分析;

(4) 保险杠蒙皮结构轻量化设计与性能校核;

(5) 轻型货车保险杠蒙皮及相关零件的图纸绘制。

目录

第1章绪论 1

1.1 研究背景及意义 1

1.1.1课题研究背景 1

1.1.2课题研究意义 1

1.2 保险杠轻量化在国内外研究现状 2

1.3 本文主要工作 2

1.3.1主要研究内容与目标 2

1.3.2技术方案及措施 3

第2章蒙皮的性能与设计要求 3

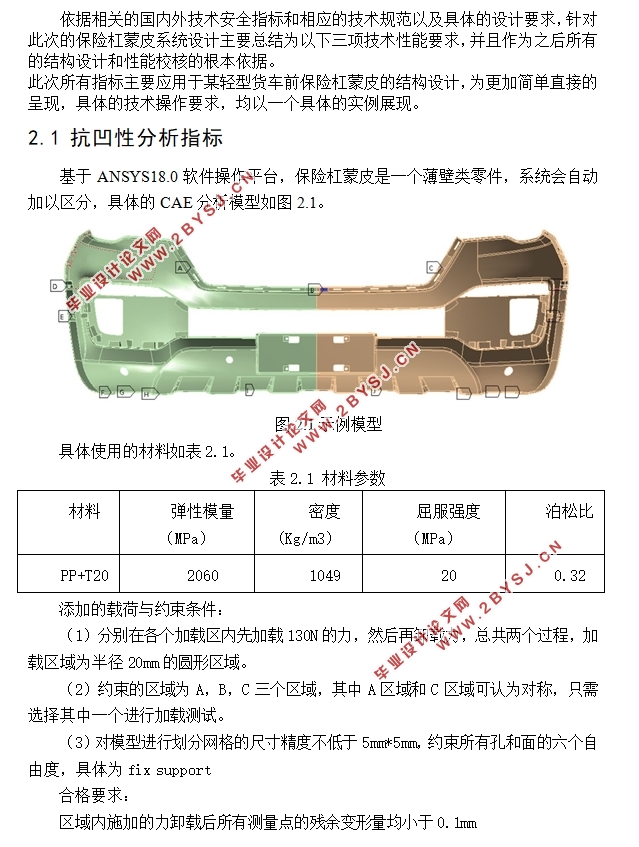

2.1 抗凹性分析指标 4

2.2 指压刚度的要求 4

2.3 模态分析指标 5

第3章蒙皮的结构性能初步CAE分析 7

3.1 模型的简化 7

3.2 初步分析结果 8

3.2.1初始模型抗凹性结果 8

3.2.2指压刚度变形量 10

3.2.3模态分析值 11

第4章蒙皮结构的轻量化设计与性能校核 12

4.1 轻量化设计方案整体构思 12

4.2 各项性能可优化空间分析 13

4.2.1次要限制因素分析 13

4.2.2主要限制因素分析 13

4.3 蒙皮结构的轻量化设计 14

4.4 轻量化蒙皮结构的性能校核 15

第5章蒙皮结构的轻量化设计总结与展望 18

5.1 轻量化结构设计总结 18

5.2 不足与展望 18

参考文献 19

致谢 21