车床主轴箱结构设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

车床主轴箱结构设计(含CAD图)(论文说明书10000字,文献综述,CAD图纸4张)

机床是讲加工成机械零件的金属坯料,它是一台机器的制造机器,也被称为工具机,所以习惯上称为机床。制造机械在现代机械制造有很多方法:除切削加工外,铸造、锻造、焊接、冲压、挤压等都是加工方法,具有较高的精度和表面粗糙度的要求是细部件,通常需要在机床上用切割方法做最后的处理。

自20世纪中叶,全球加工技术及其设备占据在制造过程中的一个重要的位置:80%以上的在制造设备的零件应进行加工,并且加工周期长,约占30-40%,产品的量产工时40-50%,处理成本高,大约100万吨钢铁和有色金属材料的切削,切削加工的耗费每年在2500亿美元以上。

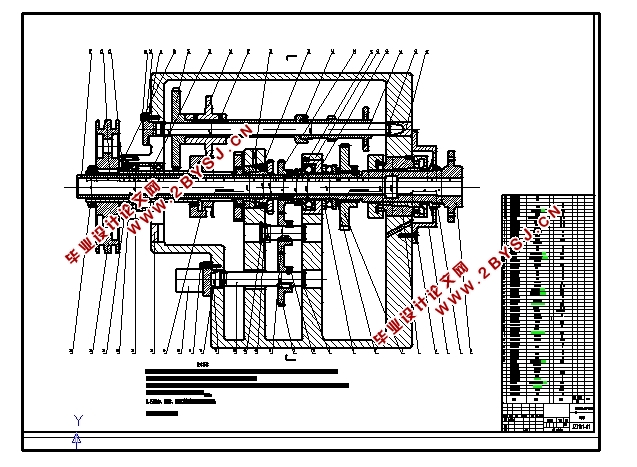

本次设计主要对机床的主轴箱进行结构设计,确定主参数设计的机床,拟定了传输方案和系统图等主要内容,对计算和验算主要零件,采用三维绘图软件设计的零部件和加工。机床主轴箱是重要的驱动部分。它将机床电动机和主轴联接起来,将被传递到主轴由电机的功率和扭矩,从而使主轴旋转来加工。它的主要功能是通过变速装置的调整主轴转速和扭矩,从而使电机运行在最佳状态。

关键词: 主轴箱; 变速; 齿轮

Abstract

Machine tool is speak metal blank processed into the machine parts of the machine, it is a machine manufacturing machine, also known as machine tool, so customarily referred to as the machine tool. Processing machinery parts in modern mechanical manufacturing processing method are many, in addition to machining, casting, forging, welding, stamping, extrusion, etc., with high accuracy and surface roughness requirements are thin parts, typically require on machine tools with cutting method for final processing.

Since the middle of the 20th century, the global processing technology and its equipment occupies an important position in the process of manufacturing: more than 80% of the parts in manufacturing equipment to carry on the processing, and processing cycle is long, accounts for about 30-40%, new product development cycle of product mass production hours 40-50%, the high cost of processing, the world about 100 million tons of steel and nonferrous materials into cutting, cutting the cost of above $250 billion a year. So the machine tool industry is the base of equipment industry, the developed countries in the world attaches great importance to its development, machine tool production continues to grow, machine output and consumption are rapid development situation of our country.

Woke up this design is mainly aimed at machine tool spindle box design, determination of main parameters design main content of machine tool, the transmission scheme and system diagram drawn up, the main parts for the calculation and checking, using 3 d drawing software to design and processing of the parts. Machine tools spindle box is important in driving part. The machine motor and spindle connected together, will be passed on to the main shaft by a motor power and torque, so that the spindle rotation to machining. Its main function is through the speed change device adjusting the spindle speed and torque, so that the motor running in the best state.

Key words: spindle box; Variable speed; gear.

目 录

第一章 引言 1

1.1 普通车床简介 1

1.2 普通车床使用条件 2

1.3 普通车床操作规程 3

1.3.1 开车前的检查 3

1.3.2 操作程序 3

1.3.3 停车操作 4

1.3.4 运行中的注意事项 4

第二章 主轴箱结构设计 5

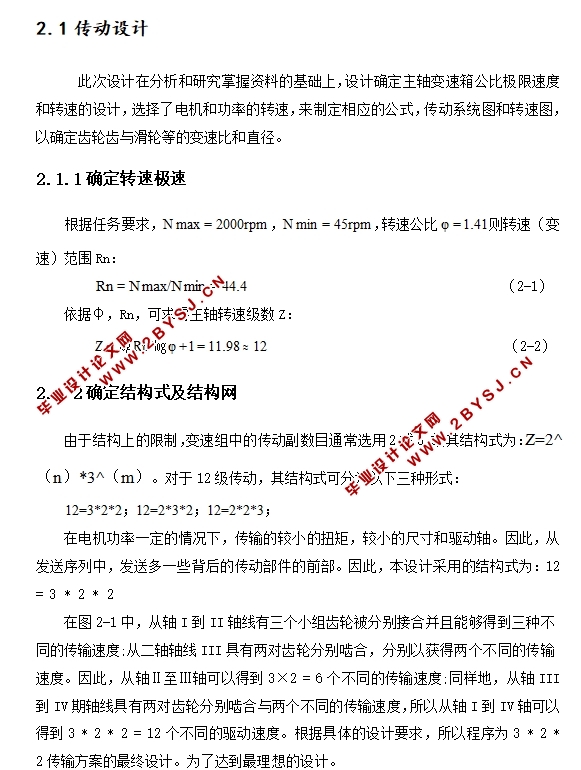

2.1传动设计 5

2.1.1确定转速极速 5

2.1.3绘制转速图 7

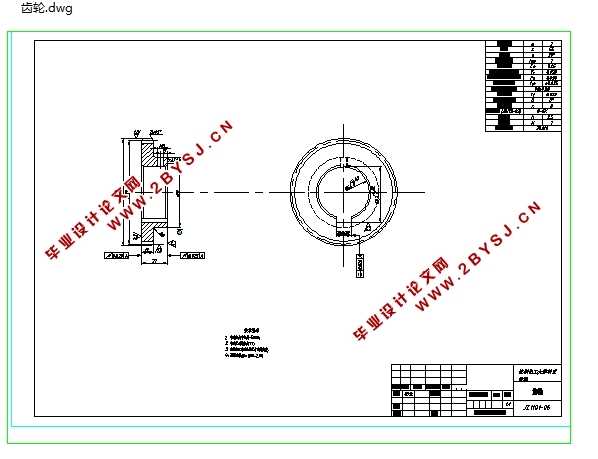

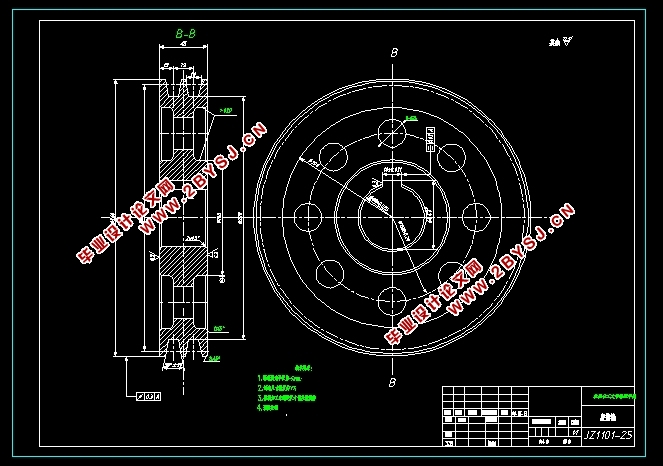

2.1.4齿轮齿数的估算 9

2.1.5带轮直径的确定 10

第三章 动力计算 11

3.1电机功率的确定 11

3.2主轴的估算 11

3.2.1主轴前端轴颈的直径D1 11

3.2.2主轴的后轴颈D2 12

3.3中间传动轴的初算 12

3.3.2计算转速N j的确定 12

3.3.3各轴传递功率的确定 13

3.4 齿轮模数的估算 14

3.5各轴直径及各齿轮齿数的确定 14

第四章 结构设计 17

4.1 齿轮的轴向布置 17

4.2 传动轴及其上传动元件的布置 18

4.2.1 Ⅰ轴的设计 18

4.2.2 Ⅱ轴的设计 18

4.2.3 Ⅲ轴的设计 19

4.2.4 Ⅳ轴的设计 19

4.2.5 Ⅴ轴的设计 20

4.2.6 主轴的设计 21

4.3 主轴的强度校核 22

4.3.1低6级传动时强度验算 22

4.3.2高6级传动时强度计算 24

总结 26

参考文献 27

致谢 28