开瓶器塑料支架模具零件的数控加工编程(UG三维图,加工工单)

无需注册登录,支付后按照提示操作即可获取该资料.

开瓶器塑料支架模具零件的数控加工编程(UG三维图,加工工单)(论文说明书13000字,UG三维图,加工工单)

摘 要

数控加工编程在在模具制造过程中具有重大的优势,高质量的编程可以满足多种模具的加工要求,并且可以充分发挥数控机床的工作性能,使用数控加工技术不仅可以极大地保证模具的精度,而且可以既方便又高效地对模具进行设计和加工。

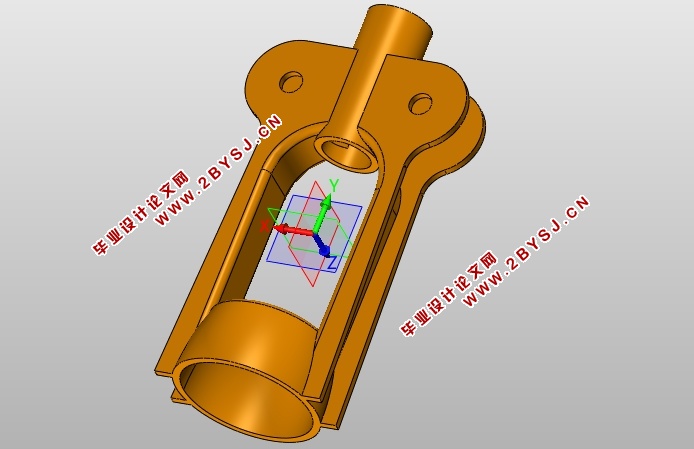

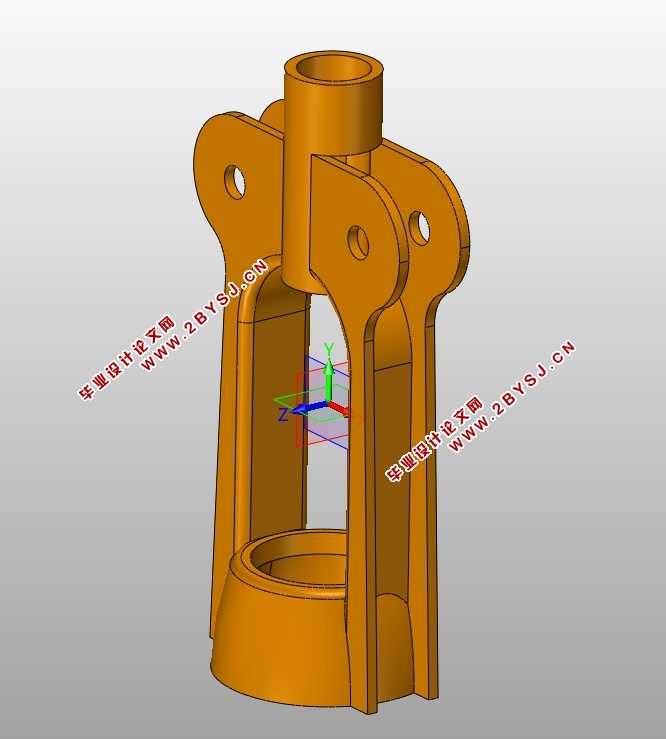

本次毕业设计中,根据开瓶器塑料支架模具数控加工要求,先对开瓶器塑料支架结构进行分析;分析开瓶器塑料支架模具的加工工艺,确定其制作工序;使用UG11.0进行开瓶器塑料支架模具零件的加工编程,后处理以及优化、仿真。生成装甲图和加工工单,完成开瓶器塑料支架模具的最优化的数控加工编程。利用CAD进行模具零件图的绘制。

数控技术的理论为机械制造提供了高速高精度高可靠性的解决方案,各类数控机床和UG NX等数控加工等软件,正是在这一理论下诞生的。它们为当前快速更新换代且形状复杂的模具行业提供了完美的解决方案。模具类零件的数控加工与编程,正是基于数控技术理论实现的模具类零件的高速高效高可靠性加工方案。

关键词:模具;数控加工编程;后处理;仿真

ABSTRACT

NC machining programming has great advantages in mold manufacturing process. High quality programming can meet many kinds of applications.

Mold processing requirements, and can give full play to the performance of CNC machine tools, CNC machining technology can not only be used

In order to guarantee the accuracy of the mould greatly, it can also design and process the mold conveniently and efficiently.

In this graduation design, the plastic support structure of the bottle opener is analyzed, the processing technology of the plastic support die of the bottle opener is analyzed, the manufacturing process is determined, and the processing programming, post-processing and optimization of the plastic support die parts of the bottle opener are made with UG11.0. It's true. Generate armored drawing and processing sheet, and complete the optimized NC machining programming of the bottle opener plastic scaffold mold. Using CAD to draw the drawing of mould parts.

The theory of numerical control provides a high speed, high precision and high reliability solution for mechanical manufacturing. All kinds of CNC machine tools and UGNX, such as NC machining software, are born under this theory. They provide a perfect solution for the rapidly updating and complex mold industry. CNC machining and programming of mold parts is based on the theory of numerical control technology to achieve high speed, high efficiency and high reliability machining program for mold parts.

Keywords: Mechanical parts design;Nc programming;CAD figure;UG NX 3 d figure.

目录

摘 要 I

ABSTRACT II

1绪论 1

1模具制造发展进程分析 1

2模具制造基础工艺要求 1

3模具数控加工技术的研究 2

2开瓶器塑料支架模具结构分析 3

2.1 开瓶器塑料支架的分析 3

2.2开瓶器塑料支架注塑模具成型部件的分析 7

3开瓶器塑料支架模具成型部件加工工艺分析 9

3.1开瓶器塑料支架模具成型部件结构分析 9

3.2数控加工顺序和刀具选择 10

4 数控加工程序编制 12

4.1开瓶器塑料支架注塑模具成型部件1的程序编制 12

4.2开瓶器塑料支架注塑模具成型部件2的程序编制 33

5 后处理 41

5.1 程序后处理 41

5.2 加工工单的生成 41

5.3装甲图的生成 41

结论 42

参考文献 43

致谢 44