500ml啤酒定量灌装机构设计(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

500ml啤酒定量灌装机构设计(含CAD零件装配图)(论文说明书18000字,外文翻译,CAD图5张)

随着我国经济的不断发展和人民生活水平的不断提高,啤酒等碳酸饮料在人们生活中占有重要地位,也带动了灌装机械的发展。啤酒灌装是啤酒生产的最后一道工序,灌装工艺和设备的优劣直接影响到啤酒的成品质量、成本和销售效果,进而影响到啤酒的整体生产效率。

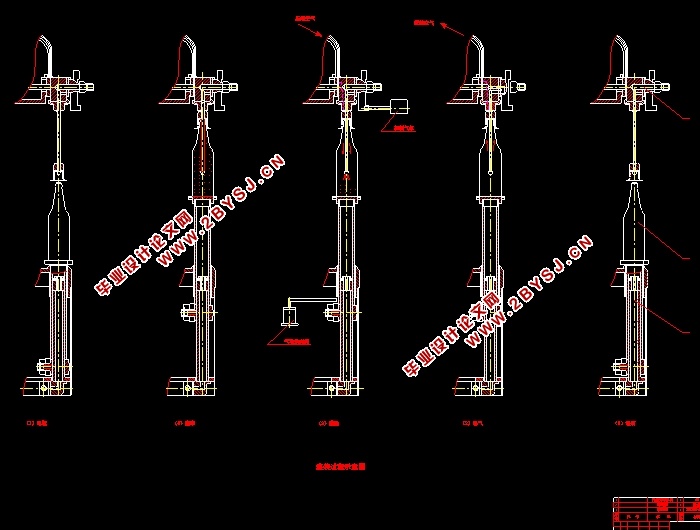

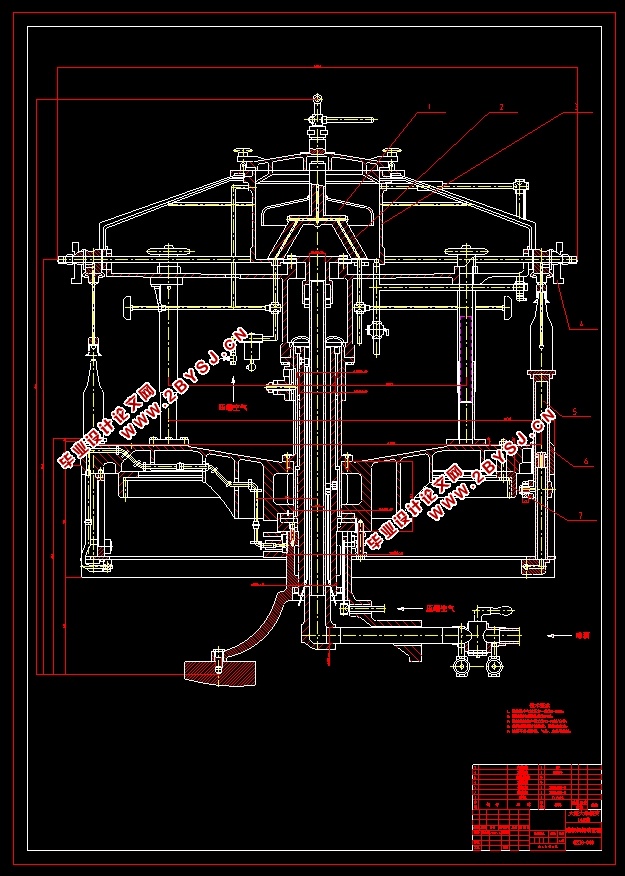

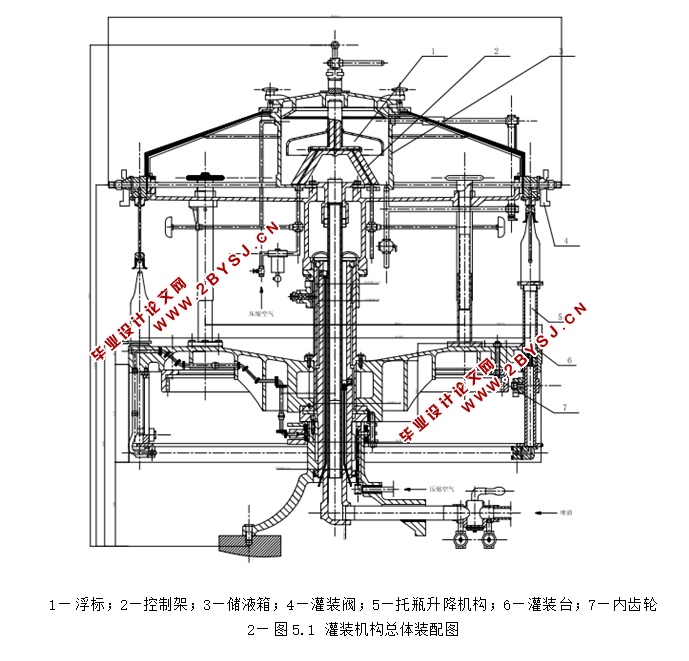

本次设计主要研究的内容是500ml啤酒定量灌装机构设计,主要包括三个部分:灌装部分的设计、托瓶升降机构的设计和辅助零件的设计。灌装部分主要是灌装阀,是灌装机执行机构的主要部分。其功能是根据灌装过程的要求,为确保灌装过程的顺利进行,要求以最快的速度连接或切断储液箱、气室和灌装容器之间的液体流动通道。本设计拟定选用盘式灌装阀。升瓶机构的作用是根据灌装过程的要求将啤酒瓶送到固定位置进行灌装,灌装完成后将啤酒瓶降到指定位置,这样送瓶机构就可以将啤酒瓶送到指定的输送链上进行输送。本次设计选择机械与气动组合式升降机构。辅助零件主要包括旋转主轴、灌装台等。

本次灌装机构的设计可以实现各个部分同步运动,以此提高啤酒灌装的准确性和高效性。同时,可实现啤酒的大量生产以及带来巨大的经济效益。

关键词:灌装机;灌装阀;机构设计

ABSTRACT

With the continuous development of our country’s economy and the continuous improvement of people’s living levels,beer and other carbonated beverages have played an important role in people’s lives and have also driven the development of filling machinery.Beer filling is the last process of beer production.The advantages and disadvantages of the filling process and equipment directly affect the finished product quality,cost and sales effect of beer, and thus affect the overall production efficiency of beer.

The main research content of this design is the design of 500ml beer quantitative filling mechanism, which mainly includes three parts: the design of the filling part, the design of the bottle lifting mechanism and the design of auxiliary parts. The filling part is mainly the filling valve and is the main part of the filling machine's actuator. Its function is to ensure the smooth progress of the filling process according to the requirements of the filling process, and it is required to connect or cut off the liquid flow path between the liquid storage tank, the air chamber and the filling container at the fastest speed. The function of the bottle raising mechanism is to send the beer bottle to a fixed position for filling according to the requirements of the filling process. After the filling is completed, the beer bottle is lowered to a designated position, so that the bottle sending mechanism can send the beer bottle to the designated conveying chain on the conveyor. The design selected mechanical and pneumatic combined lift mechanism.Auxiliary parts mainly include rotating spindles, filling tables, and so on.

The design of the filling mechanism can realize synchronous movement of various parts, so as to improve the accuracy and high efficiency of high beer filling. At the same time, mass production of beer and great economic benefits can be achieved.

Key Words:Filling Machine; Filling Valve; Structural Design

设计要求

(1)灌装阀要求能够很快的速度连通或切断储液箱、气室和灌装容器之间液体流动的通道,确保灌装工艺过程顺利进行,并且能够实现啤酒的定量控制。

(2)托瓶升降机构要求运行平稳、迅速、准确,安全可靠,结构简单,托瓶升降实现自动化。

(3)辅助零件主要包括旋转主轴和灌装台等,因此要求主轴、灌装台等满足刚度、强度等要求。

2 总体方案设计

2.1 设计参数确定

灌装部件:盘式灌装阀

灌装阀头数:24

灌装速度:72-96瓶/分钟

灌装瓶直径:75mm

灌装瓶高度:230mm

用途:灌装瓶装啤酒

生产能力:4320-5760瓶/小时

目 录

摘 要 I

ABSTRACT II

1 绪论 1

1.1 选题研究的意义与价值 1

1.2 选题研究现状及发展趋势 1

1.3 选题研究的内容 3

2 总体方案设计 4

2.1 设计参数确定 4

2.2 灌装方法确定 4

2.3 定量方法确定 5

2.4 灌装主要机构确定 7

3 灌装机构相关设计计算 12

3.1 电动机的选择 12

3.2 灌装机构输送管路的计算 13

3.3 灌装时间的确定 14

3.4 灌装传动系统的设计 15

4 主要部件的设计 22

4.1 灌装部分的设计 22

4.2 托瓶升降机构的设计 24

4.3 辅助零件的设计 30

5 灌装机构总体装配 34

6 结 论 36

参 考 文 献 37

附录1:外文翻译 40

附录2:外文原文 51

致 谢 57