YK3180滚齿机传动机构设计(含CAD图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

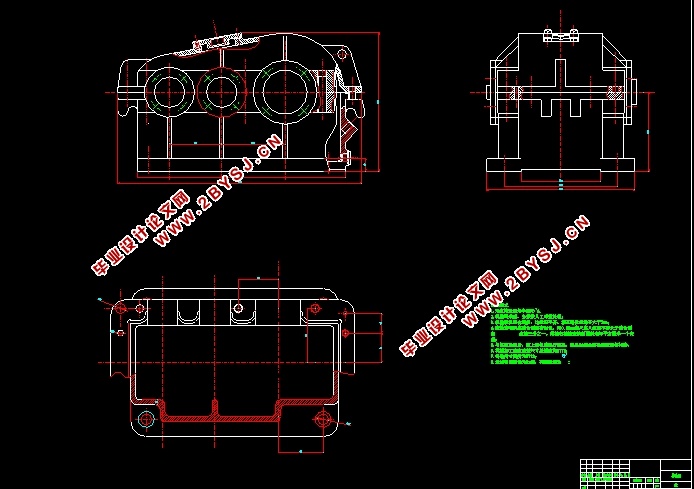

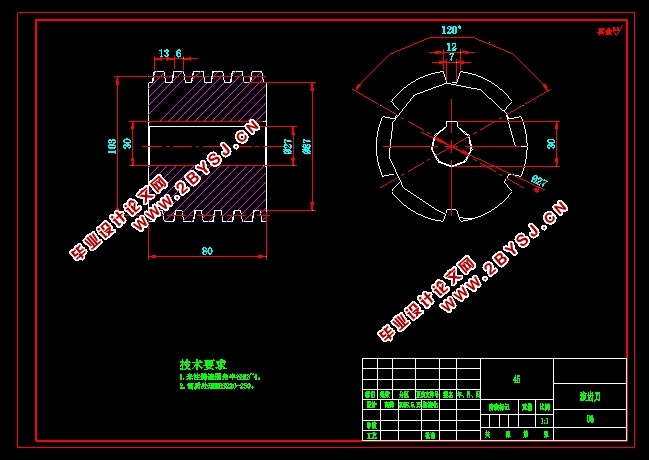

YK3180滚齿机传动机构设计(含CAD图,SolidWorks三维图)(论文说明书10000字,外文翻译,CAD图9张,SolidWorks三维图)

摘 要

滚齿机传动机构是构成滚齿机的重要组成部分,是对滚齿加工原理进行实践的关键机构。滚齿机传动系统设计的重点问题是构建范成传动链,该传动链的精度从根本上决定了机床的加工精度。

本文主要完成了YK3180滚齿机传动机构的设计计算。以阐述课题研究的主要内容和滚齿机传动机构的现状、未来的发展趋势开始,对比分析了滚齿机传动机构的多种设计方案,并且找出了最佳方案,最后对滚齿机传动机构部分进行了设计计算。滚齿机的传动机构设计是将主电机驱动的旋转运动通过齿轮副和蜗轮副转化为刀具与工件所形成的啮合运动。在设计过程中主要采用机械传动方式,基本上包含了各种比较典型和常用的机械传动,如:带传动、圆柱齿轮传动、斜齿轮传动等。总体结构设计上采用了分离式传动,能够比较直观地反映出齿轮滚齿加工的特点。

依靠对滚齿机传动机构的设计和改良可以提高滚齿机的生产效率、加工精度、丰富加工品种、减少加工成本以及减少噪音和机油等污染。通过对传统的滚齿机传动机构进行改进和优化,使得此种类型的滚齿机传动机构的使用范围更广泛,更加灵活,并且对今后的选型设计工作有一定的参考价值。

关键词:滚齿机;传动机构;主传动

ABSTRACT

The gear hobbing mechanism is an important part of the hobbing machine and it is the key mechanism for the hobbing principle. The key problem in the design of the gear hobbing machine drive system is to build a model gear chain. The accuracy of this drive chain fundamentally determines the machining accuracy of the machine tool.

This article mainly completes the design and calculation of YK3180 gear hobbing mechanism. In order to elaborate the main contents of the research and the status quo of the gear hobbing mechanism and the future development trend, a variety of design schemes for the gear hobbing mechanism were compared and analyzed, and the best solution was found. Finally, the design of the gear hobbing mechanism was performed. . The gear mechanism design of the gear hobbing machine is to convert the rotational motion driven by the main motor into the meshing motion formed by the tool and the workpiece through the gear pair and the worm gear pair. In the design process, mechanical transmission is mainly adopted, basically including various typical and commonly used mechanical transmissions, such as belt transmission, cylindrical gear transmission, and helical gear transmission. The overall structure design uses a separate transmission, which can intuitively reflect the characteristics of gear hobbing.

Relying on the design and improvement of the gear hobbing machine's transmission mechanism, it can improve the hobbing machine's production efficiency, processing accuracy, rich processing varieties, reduce processing costs and reduce noise and oil and other pollution. Through the improvement and optimization of the traditional gear hobbing machine transmission mechanism, this kind of gear hobbing machine transmission mechanism has a wider range of use, more flexibility, and has certain reference value for the future selection and design work.

Key Words:gear machining;transmission organization;main drive

目 录

摘 要 I

ABSTRACT II

1 绪论 1

1.1 本设计的研究意义及目的 1

1.2 滚齿机目前研究的概况和发展趋势 1

2 传动机构方案设计 3

2.1 滚齿加工原理选择 3

2.2 范成运动分解及各方案选择 4

2.3 各选择方案分析 5

2.4 主传动机构的结构图及传动示意图 7

2.5 计算滚刀的速度和功率并选择电动机 8

3 滚齿机传动部分相关计算 11

3.1 机床传动系统分析 11

3.2 主传动链的计算 12

3.3 带轮的设计计算 15

3.4 齿轮材料的选择和校核 16

3.5 轴的校核 22

4 结 论 27

参 考 文 献 28

附录1:外文翻译 29

附录2:外文原文 31

致 谢 34