电线加工自动系统设计(含CAD零件装配图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

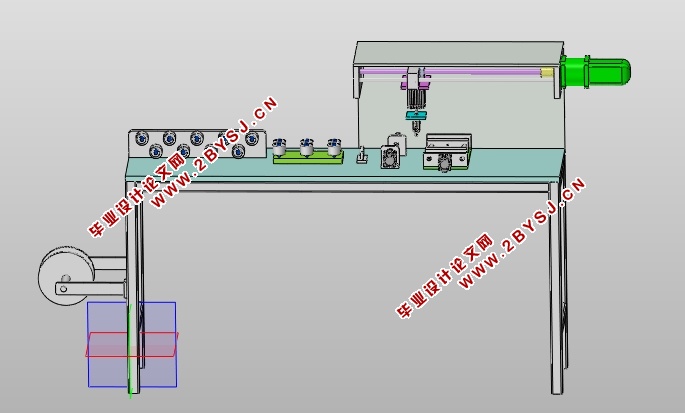

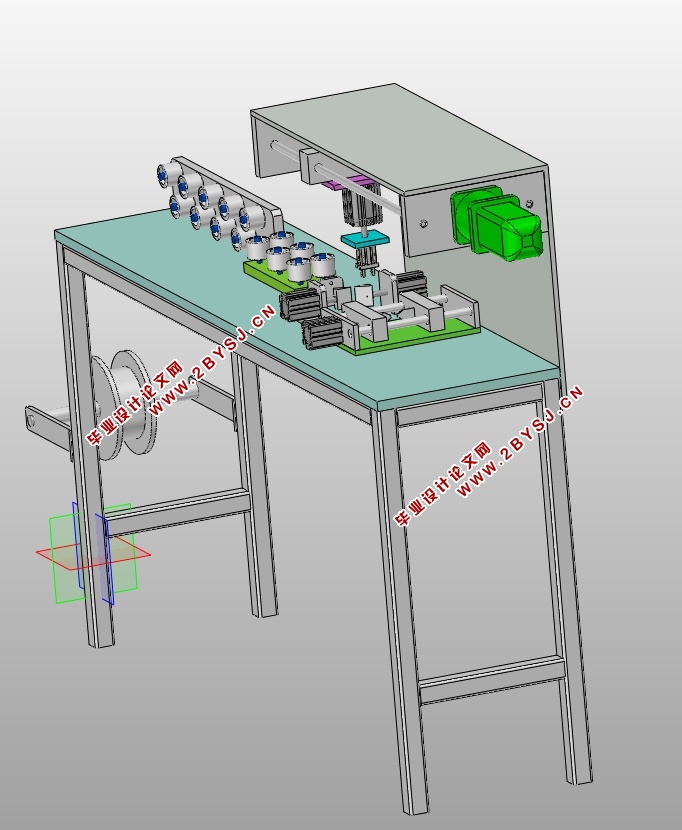

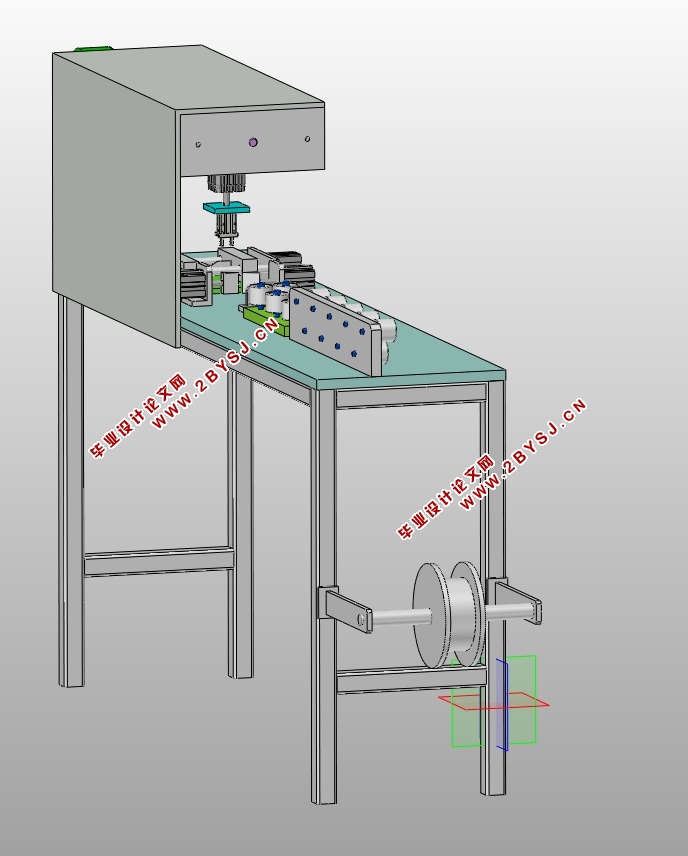

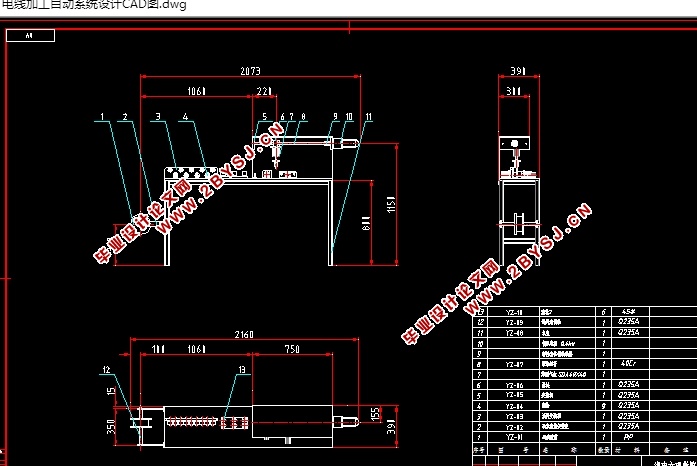

电线加工自动系统设计(含CAD零件装配图,SolidWorks三维图)(任务书,论文说明书14000字,CAD图纸10张,SolidWorks三维图)

摘 要

电源,照明灯是人们日常生活起居的重要工具,没有照明,人们就过着漆黑的生活,给日常起居带来极大的不便。特别是对于需要用到电能的工业设备上面,如果没有电源,就不能工作,电能是人类不可或缺的重要能源之一。而电线是承载电能的载体,所以电线的作用至关重要,而电线的加工设备和工艺的问题,就是我们迫切需要解决和完善的重大问题之一。

传统的电线加工大多是采用手工加工完成,加工效率低,劳动强度大,加工产品质量不稳定,为了提高生产效率,减少企业成本,提高产品质量,利用PLC的控制功能来实现电线的自动加工过程,控制速度快,定位精度高,而且体积小,结构紧凑,通信稳定可靠。它解决了现有的电线加工中的设备的不足,以及效率的低下

等等一系列问题。

关键词:电能;载体;电线加工;PLC。

Pneumatic manipulator is a automated devices that can mimic the human hand and arm movements to do something,aslo can according to a fixed procedure to moving objects or control tools. It can replace the heavy labor in order to achieve the production mechanization and automation, and can work in dangerous working environments to protect the personal safety, Therefore widely used in machine building, metallurgy, electronics, light industry and atomic energy sectors.

This article is mainly of the pneumatic manipulator the overall design, and pneumatic design. This mechanism of manipulator includes cylinders and claws and connectors parts, it can move according to the due track on the movement of grabbing, carrying and unloading. The pneumatic part of the design is primarily to choose the right valves and design PLC pneumatic control loop, by controlling and regulating pressure, flow and direction of the compressed air to make it get the necessary strength, speed and changed the direction of movement in the prescribed procedure work.

Key word: pneumatic manipulator;cylinder;pneumatic loop;PLC

目录

摘要 3

Abstract 4

第一章绪论 5

1.1课题的来源与研究的目的与意义..............................................................................7

1.2电线加工自动系统设计的方案分析.........................................................................8

1.2.1 结构分析..................................................................................................................10

1.2.2 机械结构总体方案与布局........................................................................12

1.2.3电线加工自动系统工作原理.....................................................................14

第二章、电线加工自动系统总体结构的设计...................................17

2.1电线加工自动系统的方案分析和工作原理..................................................19

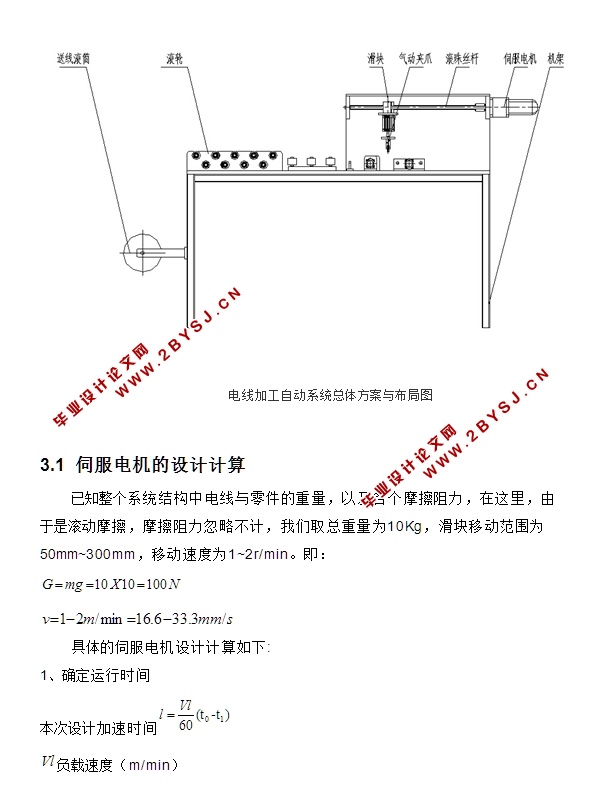

2.2 机械结构总体方案与布局..............................................................................21

第三章机械结构的设计........................................................................................24

3.1 伺服电机的选型计算..........................................................................................25

3.2 滚珠丝杆的设计计算.......................................................................................25

3.3 联轴器的设计计算............................................................................................26

3.4 机架的设计.........................................................................................................26

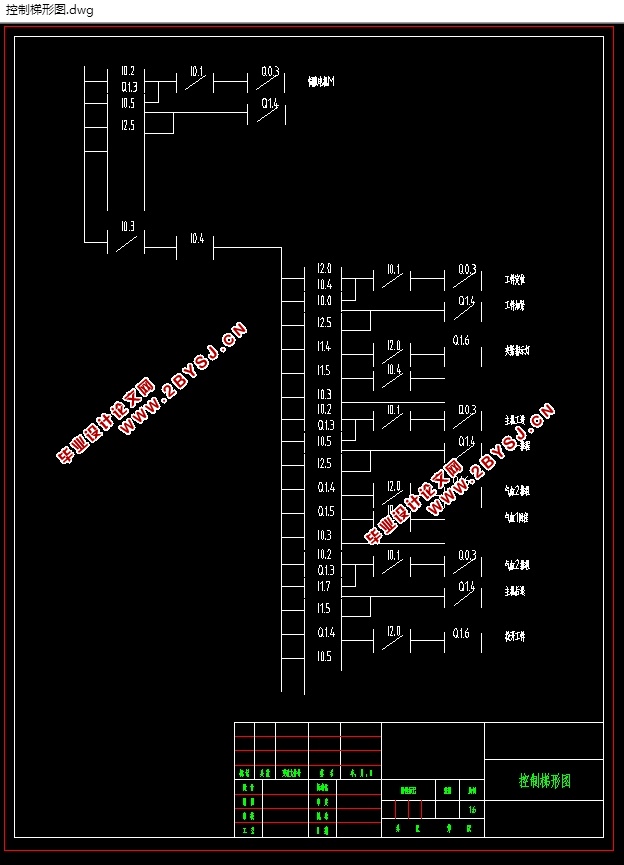

第四章电线加工自动系统设计PLC控制系统的设计................26

4.1PLC简介..................................................................................................................27

4.2 PLC的定义...........................................................................................................28

4.3 PLC的基础知识...................................................................................................29

4.4 PLC的组成...........................................................................................................30

4.4.1中央处理单元.................................................................................................31

4.4.2存储器.............................................................................................................31

4.4.3输入输出单元................................................................................................33

4.4.4通讯接口.........................................................................................................34

4.4.5智能接口模块..................................................................................................34

4.4.6编程装置.........................................................................................................35

4.4.7电源..................................................................................................................35

4.5 PLC的用途.............................................................................................................35

4.6可编程控制器的发展史.......................................................................................36

4.7 PLC的发展趋势.....................................................................................................36

4.8 PLC的选型及硬件配备........................................................................................37

4.9输入输出方式的选择与地址分配和PLC控制相关原理图的设计.....................37

结论..................................................................................................................................38

致谢 39

参考文献......................................................................................................................40