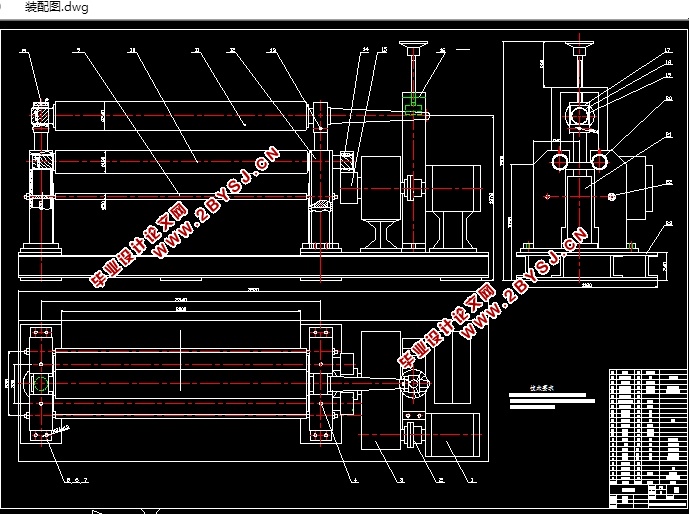

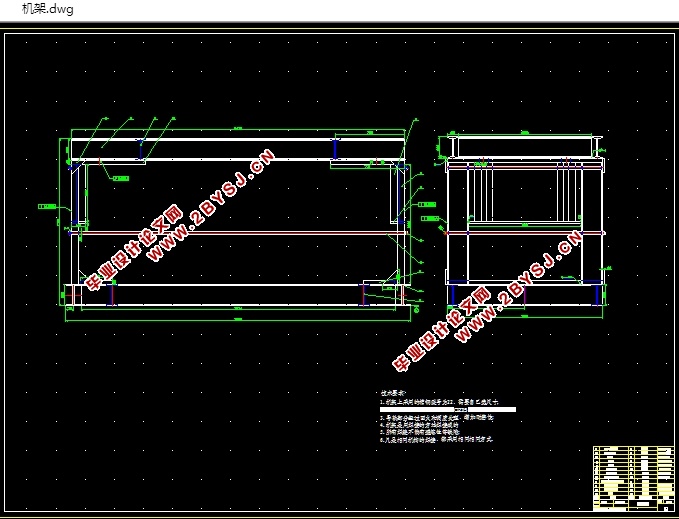

对称式三辊卷板机机构和设计改进(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

对称式三辊卷板机机构和设计改进(含CAD零件装配图)(论文说明书17000字,CAD图纸4张)

摘 要

卷板机是一种将金属板料弯卷成筒体、锥体、曲面体或其他形体的一种专用锻压机械设备,广泛用于锅炉、造船、化工、金属结构及机械制造行业。本课题的研究宗旨在改进旧式卷板机的不足,提高生产率、降低工人劳动强度,满足厂方对板料加工的生产需求。卷板机的规格型号很多,按卷板机的机械结构和卷板机辊的数量划分,有三辊卷板机和四辊卷板机之分,按辊的驱动方式有机械式卷板机和液压式卷板机之分,卷板机结构相对简单,三辊当中有一对侧辊和一根上辊,其中上辊能够上下移动。四辊卷板机结构相对复杂,有一对侧辊和一根上辊和下辊,这种卷板机成本很高,但性能较好,卷制成品质量较好。各种卷板机,工作原理都相同,通过调整上辊和侧辊的相对位置,使板料在辊之间逐渐弯曲变形,用主轴的正反转使板料在辊之间来回运动直至板料产生塑性变形。随着辊的相对位置的不断调整,主轴不断的往复正反转运动,板料的塑性变形量逐渐加大,直至加工成符合要求的圆弧或圆筒型成品。

关键词:卷板机;驱动方式;卸料装置

ABSTRACT

Bending Machine is a sheet metal bending to vol-cylinder, cone, the surface of a body or other special forging machinery and equipment, widely used in boilers, shiPBuilding, chemical, metal structures and machinery manufacturing industries. The subject of study aimed at improving the shortcomings of old Bending Machine, increase productivity and reduce labor intensity of workers to meet the sheet metal processing factory on the production demand. Bending Machine the specifications of many models, according to the mechanical structure Bending Machine Bending Machine and the number of rolls, three roller coiling machine and four roller coiling machine of points, according to Rolls-driven approach is a mechanical Bending Machine Bending Machine and a hydraulic-Bending Machine structure is relatively simple, three-roll of a contralateral on a roll and roll, which can move up or down on the roll. 4 roller coiling machine relatively complicated structure, a contralateral on a roll and roll and roll under, the high cost of such Bending Machine, but better performance, better quality products Vol. Various Bending Machine, is the same principle, by adjusting the roll and roll side of the relative position so that the sheet roll in between gradually bending deformation, with the positive and the main sheet roll back and forth between the movement until the board Material produced plastic deformation. With the roll of the relative position of the constant adjustments, the main axis of reciprocating positive and movement, the sheet of plastic deformation gradually increased until processed into line with requirements of the arc or Yuantong-finished products..

Keywords :Bending Machine;drive;unloading device

目 录

1 绪论 1

1.1 目前卷板机存在的问题 1

1.2 国内外卷板设备的技术现状 1

1.3 本课题研究的内容 2

2 卷板原理及工艺理论 3

2.1 卷板原理 3

2.2 卷板工艺及卷板质量分析 12

3 工艺分析和数学模型建立 16

3.1 原有卷板设备存在的问题 16

3.2 新型卷板机方案的确定 17

4 设计方案的确定 22

4.1机械系统方案设计 22

4.2液压系统方案设计 24

4.3 设备特点 26

5 参数的确定 27

5.1工艺参数的计算 27

5.2 液压缸的设计计算 29

5.3 液压泵的选择 32

5.4 下辊疲劳强度安全系数校核 33

5.5 螺栓连接强度的校核 34

5.6 活塞杆的强度校核 34

5.7 杆端部轴剪切和挤压强度条件 35

结 束 语 36

参考文献 37

致 谢 38