PE10自行车无级变速器的设计(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

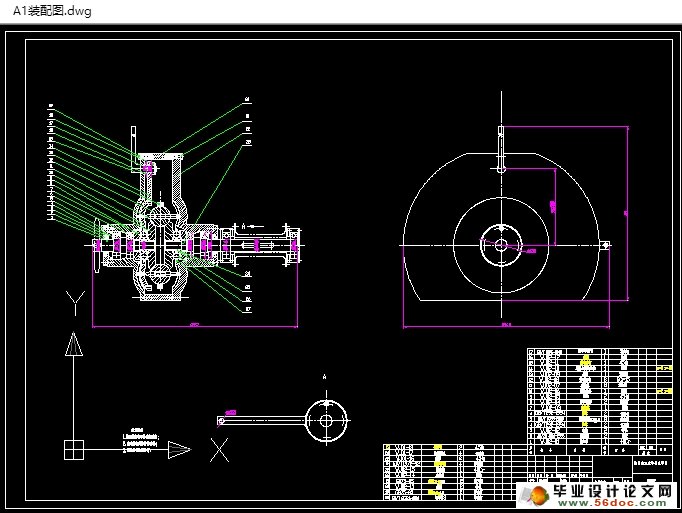

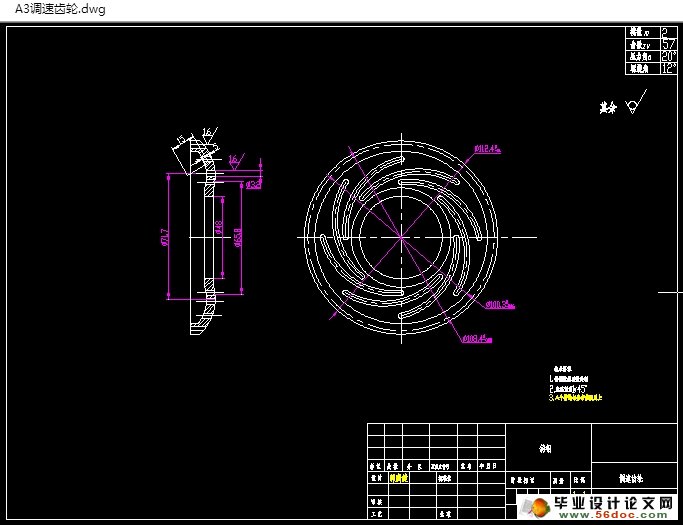

PE10自行车无级变速器的设计(含CAD零件装配图)(任务书,文献综述,设计说明书11700字,CAD图纸4张)

摘要

在本文中,考虑到钢球圆锥式无级变速器以外的局部修改和改造,不仅是无级变速器或无级变速自行车的分析。这种钢球式的变速器,是一种进一步的研究和分析。对于这种改造后的无级变速器应用于自行车的无级变速装置中,一个大大提高其性能和功能。这个装置是通过八钢球进出相互摩擦河的输出功率,使用一对斜齿轮索引速度调节,然后进行自行车0.75〜1.22之间无级调速。这种改造是对自行车无级变速的另一种应用,使用八个钢球利用摩擦的输出方式,是一种新的尝试,是一种新的应用,这种研究在原有无级变速器的基础上的应用,这些研究表明:无级变速器在自行车方面的应用非常广泛,而且性价比极高,使用价值和性能也得到了相当大的改善和改良。

在人们的生活中,可以得以更大的利用,无级变速装置,可以缓解人们对自行车的使用的局限性,会给人们带来更大的方便。它采用一个带和工作主体,驱动直径车轮传递动力,可实现连续变化,传动比和最佳匹配变速器和发动机的工作条件。

而现在,这种新类型的传输更适合于现在的生活。自行车自动无级变速器,自行车自动无级变速其使用。它由两个仅单向旋转方向由链轮和两个滚子的调控,以形成一个链。链轮可以像普通自行车链轮轮辋牵引链传动自行车后轴。齿轮系安装在传递臂,齿轮系,弹簧组,支架和轴向移动和机构,在链条张力的变化,链轮尺寸将是宽还是窄。从而实现无自行车驱动自动无级变速中断。使用自行车行驶阻力小时的传输可以生长普通自行车相比,并在丘陵或满足大风循环阻力是很大的,可以省时省力。

随着各种自行车无级变速器的出现,例如,其中包括大直径改变滑轮,小直径改变皮带轮,传动带和滑轮控制可变直径变速机构,大直径的变化,每个滑轮和小直径变化安装在中心轮自行车和后轴轴,连接驱动皮带传动,换挡齿轮固定在两个皮带轮齿轮箱之间。本实用新型具有结构简单,操作方便,性能可靠,调速范围大,非常适合安装和使用中的各种变速自行车。

而本文研究的钢球外锥式无级变速器也是诸多新型无级变速器中的一个。

关键字: 无级变速自行车; 无级变速装置; 方便; 应用广泛

Abstract

In this paper, in view of the steel ball outside cone type step less transmission for local modification and transformation, not only is step less transmission, or CVT analysis of bicycle. The transmission of ball type, is a further research and analysis. For this kind of modified step less transmission used in bicycle step less speed change device, can greatly improve its performance and function. This device is through eight steel ball in and out of the output power of the mutual friction river, using a pair of helical gear indexing speed regulation, and then make the bike for step less speed regulation between 0.75 ~ 1.22.This kind of transformation is another application of bicycle infinitely variable speed, using the output of the eight ball using friction, is a kind of new try, is a new application, the research on the basis of the original step less transmission applications, these studies show that the step less transmission has a very wide range of applications in the bike, and high cost performance, use value and performance has been considerable improvement and improvement.

In the life of people, can be to be able to use a larger, step less speed change device, can relieve people's limitations to the use of bicycles, can bring more convenience to people. It USES a belt and the work the main, driven wheel in diameters to transfer the power, can realize continuous change, the transmission ratio and the best matching transmission and engine working conditions.

And now, this new type of transmission is more suitable for life now. A bicycle automatic step less transmission, which used in bicycle automatic step less variable speed. It consists of two only unidirectional rotating direction by the regulation of sprocket and two roller to form a chain. Sprocket can be like ordinary bicycle sprocket rim drag chain drive bike rear axle. A gear train is installed in the transmission arm, gear train, spring group, stents and axial moving and institutions, in the chain tension changes, the sprocket size will be wide or narrow. So as to realize without interruption of bicycle drive automatic step less variable speed. Compared with ordinary bikes using the transmission on bicycle travel resistance hours can be growth, and in the hills or meet strong wind cycling resistance is big, can save Labour.

Have been all kinds of bicycle step less transmission, for example, including the big diameter changes pulley, small diameter changes pulley, drive belt and pulley control variable diameter variable speed institutions, large diameter changes, each pulley and small diameter changes pulley installed on the center axis of the bicycle and rear axle, connect drive belt transmission, shift gear is fixed between the two pulley gear box. The utility model has simple structure, easy operation, reliable performance and speed range is big, very suitable for the installation and use in a variety of variable speed bicycle.

And in this paper, we study the ball cone type step less transmission also is one of the many new type step less transmission.

Keyword: CVT bike, CVT , Convenience, Widely used

目 录

第一章 绪论 1

1.1 机械无级变速器的发展概况 1

1.2 机械无级变速器的特征和应用 2

1.3 无级变速自行车研究现状 3

1.4 毕业论文设计内容和要求 5

第二章 自行车无级变速器总体方案的选择 6

2.1 钢球长锥式(RC型)无级变速器 6

2.2 钢球外锥式无级变速器 7

2.3 两方案的比较与选择 8

第三章 钢球外锥式无级变速器部分零件的设计与计算 9

3.1 钢球与主﹑从动锥齿轮的设计与计算 9

3.2 加压盘的设计与计算 10

3.3 调速齿轮上变速曲线槽的设计与计算 11

3.4 输入轴的设计与计算 12

3.5 输出轴的设计与计算 15

3.6 输入﹑输出轴上轴承的选择与计算 18

3.7 输入﹑输出轴上端盖的设计与计算 20

3.8 调速机构的设计与计算 21

3.9 自行车无级变速器的安装 22

参考文献 24

致谢 25