100T液压机液压缸系统设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

100T液压机液压缸系统设计(含CAD图)(文献综述,设计说明书10000字,CAD图纸2张)

摘要

液压机也称为油压机,它是一种利用液体静压力来加工金属、塑料、橡胶、木材、粉末等制品的机械,通常情况下主机为三梁四柱的结构,三梁四柱式这种液压机结构经济实用,从而广泛的应用在机械制造中。液压机是一种使用液体的压力用来传递机械能,液压控制可以适当采用插装阀集成系统,动作稳定,工艺流畅,使用重复次数较多,液压的冲击惯性较小,缩短了连接管路与泄露点之间的距离,或一般液压控制两种形式,它们可用于各种可塑性材料的压力加工技术和成型技术,如冲裁技术、弯曲技术、翻边技术、薄板拉伸技术等。基本原理是由油泵把液压油输送到集成的插装阀块之中,通过各种单向阀和溢流阀把液压油分配到油缸的上腔系统或者下腔系统中,在高压油的强大作用力之下,使油缸进行往复机械运动。液压机是使用液体来传递机械压力的机械设备。清洗零件和轴的各连接处并及时加润滑油,从而实现液压程序的操纵灵动性。仔细看查并且紧住上缸盖和下缸盖、电机座和锤身地脚螺丝,必须保证拧紧坚固。单位流量欠缺或没有流量的原因:液压缸系统的工作效率低,出现在设备刚刚正常启动的时候,液压缸工作机构运行比较慢、工作声音正常,有压力却没有流量。当液压缸发生这种情况的时候,就必须检查机械系统和换向阀这两部分。因为没有多余的零件更换,再次生产零件的时间不是很清楚,长时间的机器闲置会给企业带来巨大的经济损失,并且还要支付很多钱来维修。因为当今企业要走机械化和数控化的道路,需要找到方便快捷,行之有效的方法来保养和维修这些机械设备,否则企业得不偿失,从而最大化企业的经济效益。企业可以采用很多种方法进行现场维修,比如找专业的修理人员进行修理。

关键词: 液压机; 机身结构; 工作压力; 滑块

Abstract

Hydraulic machine, also known as hydraulic machine, it is a by liquid static pressure to the processing of metal, plastic, rubber, wood powder and other products, machinery, usually host for the structure of the three beams and four columns, three four beam of the hydraulic machine structure is economical and practical, so it has a wide range of applications in machinery manufacturing. Hydraulic machine is a kind of using liquid pressure used for the transmission of mechanical energy, hydraulic control can be suitably used cartridge valve integrated system, stable operation, smooth process using repeated many times, the impact of hydraulic inertia is small, shortening the connecting pipe and the discharge distance between the dew point, or general hydraulic control two kinds of forms, they can be used for all kinds of plastic material pressure processing technology and molding technology, such as punching blanking, bending, flanging technology, sheet metal drawing technology etc.. Basic principle is by the oil pump to the hydraulic oil is transported to the integrated cartridge valve blocks among, through a variety of one-way valve and the overflow valve to hydraulic oil distribution to the cylinder chamber system or inferior system, under the strong force of the high pressure oil, the oil cylinder for reciprocating mechanical movement. Hydraulic machine is the use of liquid to transfer mechanical and mechanical equipment. Clean parts and shaft of the connecting department and add the lubricating oil, so as to realize the operation of the hydraulic program.. Carefully check and hold on tight under the cylinder head and cylinder head, a motor seat and a hammer body screws, tighten the firm must ensure that. Reasons for the lack of per unit of flow or no flow: hydraulic cylinder system work efficiency low, appear in the device just starting when, hydraulic cylinder mechanism relatively slow, normal voice, pressure without traffic. When the hydraulic cylinder occurs in this case, it is necessary to check the mechanical system and the two parts of the valve. Because there is no spare parts replacement and once again producing parts of the time is not very clear, the long time idle machines will bring huge economic losses to the enterprise, and also pay a lot of money to repair. Because today's enterprises to walk the road machinery and CNC, the need to find a convenient and effective approach to maintenance and repair of the mechanical equipment, otherwise enterprises gain to maximize the enterprise economic benefit. Enterprises can use many methods for on-site maintenance, such as looking for professional repair personnel for repair.

Key words: Hydraulc press, Fuselage structure, Working pressure, Slider

目 录

第一章 绪论 1

1.1液压机的发展 1

1.2 液压机的工作原理 1

1.3四柱液压机的用途、特点和主要性能 2

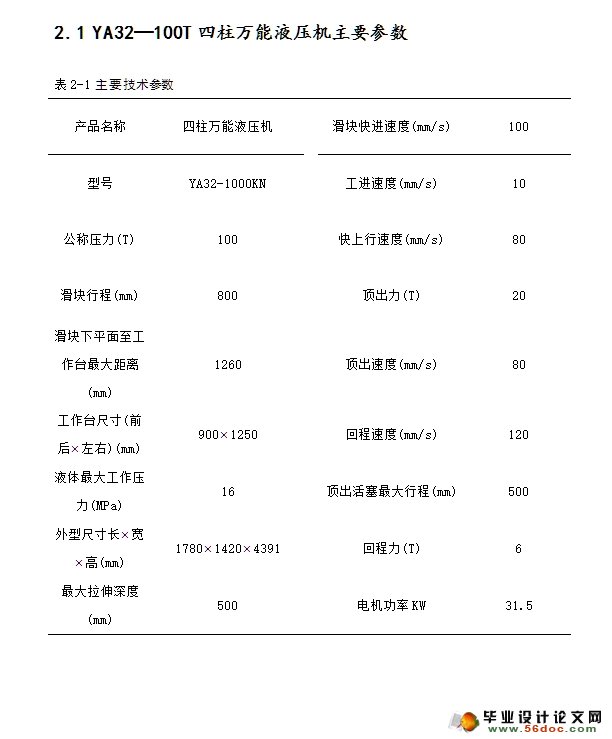

第二章 液压机的主要技术参数 3

2.1 YA32─100T四柱万能液压机主要参数 3

2.2 YA32─100T四柱万能液压机系统工况图 4

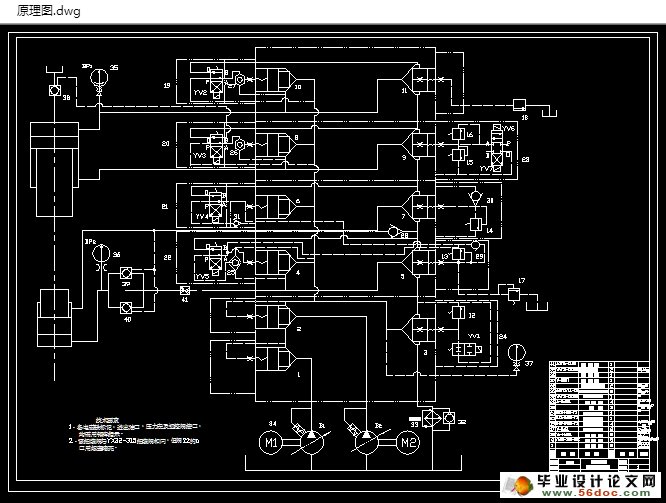

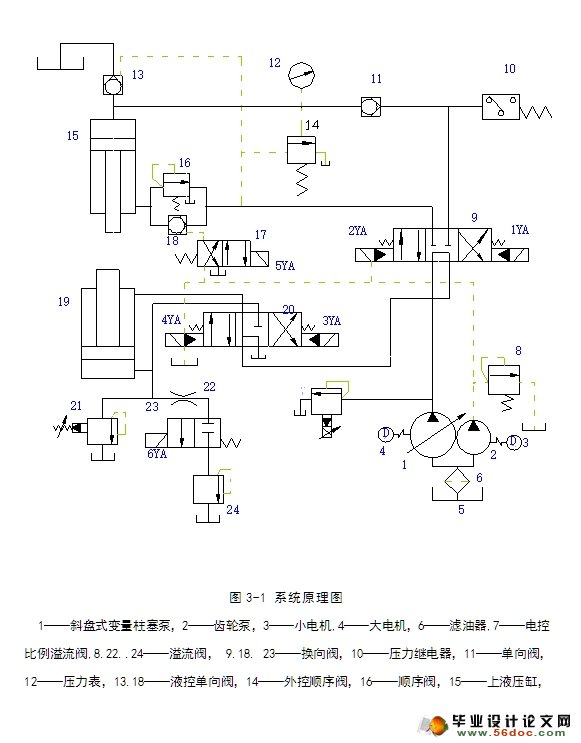

第三章 液压基本回路以及控制阀 6

3.1 YA32─100T四柱万能液压机液压系统图 6

3.2 YA32─100T四柱万能液压机工作循环图 9

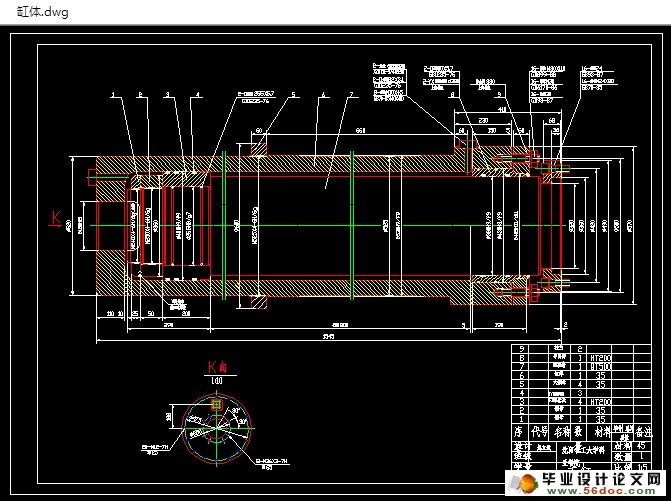

第四章 液压缸 10

4.1 主缸 10

4.1.1 材料 11

4.1.2 缸筒内径: 11

4.1.4 缸筒壁厚: 17

4.1.5 缸筒壁厚校核: 17

4.1.6 缸筒的暴裂压力: 18

4.1.7 缸筒底部厚度 18

4.1.8 缸筒端部法兰厚度:h 19

4.1.9 缸筒法兰连接螺栓 19

4.2 主缸活塞杆 20

4.2.1 材料 20

4.2.2 直径 20

4.2.3 强度校核 20

4.3 主缸的总效率 21

4.3.1 机械效率 21

4.3.2 容积效率 21

4.3.3 反作用力效率 21

4.4 各油缸工作流量 22

4.4.1 主缸快速下行 22

4.4.2 主缸工进 22

4.4.3 主缸回程 23

4.4.4 液压缸损坏情况及原因分析 23

第五章 液压系统的安装 25

5.1 液压元件的安装 25

总 结 26

参考文献 27

致 谢 28