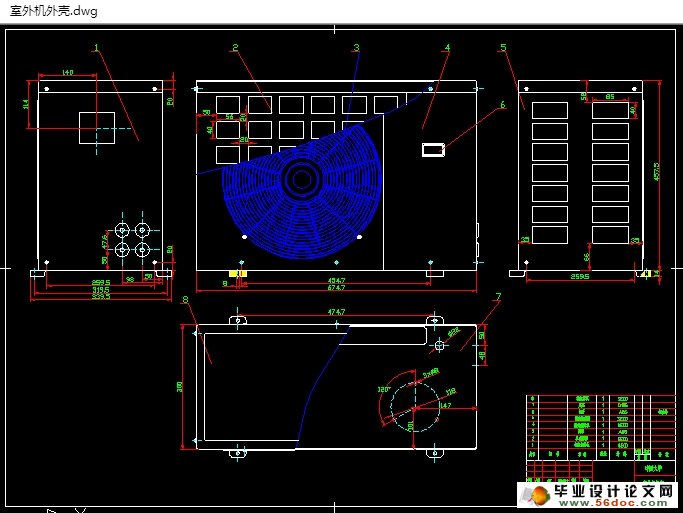

一拖二热泵型空调器(KFR-20GW×2)(热能与动力工程)(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

一拖二热泵型空调器(KFR-20GW×2)(热能与动力工程)(含CAD图)(开题报告,文献综述,外文翻译,论文设计说明书18300字,CAD图纸7张)

摘 要

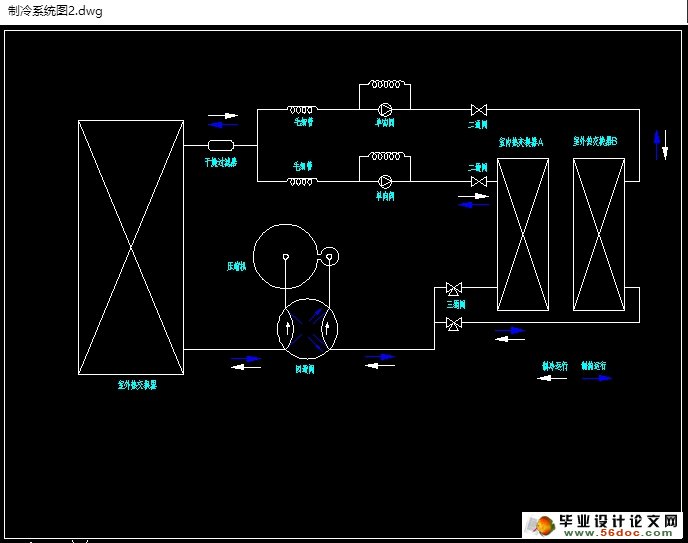

本文简单介绍热泵分体式一拖二空调的设计中的几个问题:新型绿色制冷剂的使用,热力循环的计算,蒸发器和冷凝器的计算,空调器附件的选择,以及热泵型房间空调器的发展和展望。

空气调节顾名思义是对空气的参数进行调节,以便使环境更适合我们的要求。随着我国国民经济的发展和人民生活水平的提高,人们对生活环境的条件要求也在逐步的提高。所以空气调节在日常生活中占有很重要的位置。也使的空调技术在不断的提高,以达到人们对环境的要求。热泵型房间空调器既可制冷又能制热,能满足冬夏两季节的要求而得到快速发展。其的新品种越来越多,性能也越来越优良。空调器朝着小型化,节能化,智能化,美观化,健康化的方向发展。

近年来,随着住宅条件的改变,一些用户出于节省空间的考虑,开始购买一拖二空调器,促进拉一拖二空调器的发展和改进。

关键词 热泵/一拖二空调/新型制冷剂/节能/环保

"one-drivers-two" heat pump air-conditioner(KFR-20GW×2)

ABSTRACT

This article simply introduced the heat pump"one-drivers-two"room air-conditioner in design several questions: New green refrigerant use,the calculation of the thermodynamic energy circulation, evaporator and condenser computation,air-conditioner appendix choice, as well as heat pump room air-conditioner development and forecast.

The air conditioning is as the name suggests carries on the adjustment to the air parameter, in order to cause the environment to suit our request. With development of our country national economy and the improvement of the people's lives level,people's living conditions condition request also in gradually enhancement. Therefore the air conditioning holds the very important position in the daily life. Also causes the air conditioning technology in the unceasing enhancement, achieves the people to the environment request. The heat pump room air-conditioner both can make cold and heat, can satisfy the requests of the winter and summer, so it gets a fast development. The air-conditioner is facing the miniaturization, the energy conservation, the intellectualization, is artistic, the health direction develops.

In recent years, along with the housing condition change, some users stemming from saved spatial the consideration, started to purchase "one-drivers-two" air-conditioners, the promotion pulls as soon as tows two air-conditioners the development and the improvement.

KEY WORDS The heat pump , One-drivers-two air-conditioner, New green refrigerant,

Energy conservation, Environmental protection

目 录

中文摘要---------------------------------------------------------------Ⅰ

英文摘要---------------------------------------------------------------Ⅱ

绪 论---------------------------------------------------------------1

1热力循环计算--------------------------------------------------------8

1.1设计工况的选择------------------------------------------------8

1.2热 力 计 算----------------------------------------------------8

1.2.1 R407C在制冷工况下热力循环计算---------------------------8

1.2.2 R407C在制热工况下热力循环计算---------------------------11

1.2.3 R22在制冷工况下热力循环计算-----------------------------13

1.2.4 R22在制热工况下热力循环计算 ----------------------------15

2 换热器设计计算----------------------------------------------------17

2.1 冷凝器的设计计算-------------------------------------------17

2.2 蒸发器的设计计算-------------------------------------------23

3 毛细管的设计计算-------------------------------------------------30

4 辅助元件的选型 --------------------------------------------------32

4.1压缩机的选型--------------------------------------------------32

4.2轴流风机的选型-----------------------------------------------34

4.3贯流风机的选型-----------------------------------------------35

4.4 四通换向阀的选型-------------------------------------------35

4.5截止阀的选型 ------------------------------------------------36

4.6单向阀的选型-------------------------------------------------37

4.7干燥过滤器的选型--------------------------------------------38

5两种热泵型空调系统的对比研究--------------------------------39

5.1 无氟替代的必然性------------------------------------------39

5.2 方案论证-----------------------------------------------------40

5.2.1制冷剂R22与R407c的分析比较------------------------40

5.2.2 R407C与R22两种制冷剂系统的比较-----------------------42

5.3 结论---------------------------------------------------------44

总 结--------------------------------------------------------------45

致 谢 -----------------------------------------------------------46

参考文献------------------------------------------------------------47

(附录)------------------------------------------------------------48

附录1 制冷系统流程图-------------------------------48

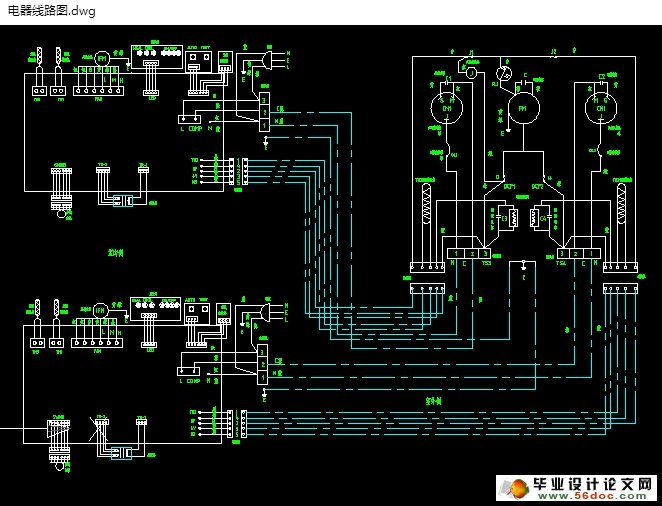

附录2 电器控制接线图-------------------------------48

附录3 冷凝器设计计算程序---------------------------49