采煤机滚筒的设计(含CAD零件装配图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

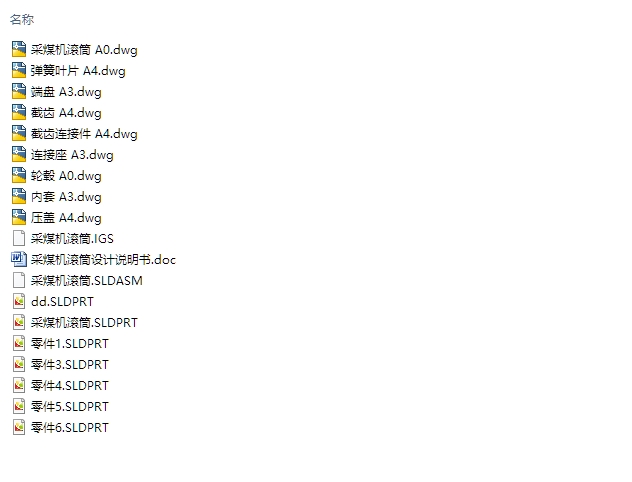

采煤机滚筒的设计(含CAD零件装配图,SolidWorks,IGS三维图)(论文说明书12500字,CAD图纸9张,SolidWorks三维图,IGS通用三维格式)

摘 要

采煤机是煤矿综采工作中的关键机械设备之一,大功率、高强度、高可靠性是现代采煤机发展方向。

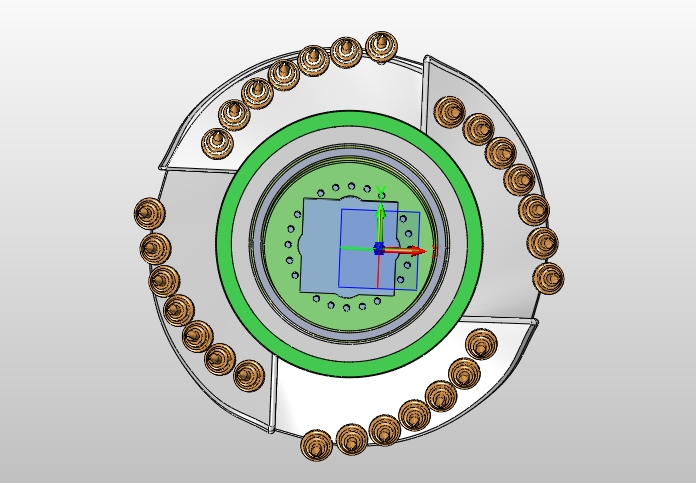

本论文完成了采煤机滚筒的设计,对滚筒中的组成部件都做了具体分析计算,重点对滚筒的结构进行了优化设计。包括滚筒的布局设计及三维建模。文中主要介绍了目前国内外采煤机的研究现状及未来发展趋势,同时介绍了采煤机滚筒的类型、工作原理和主要组成,还介绍了采煤机滚筒的具体结构。

本文运用大学所学的知识,提出了采煤机滚筒的结构组成、工作原理以及主要零部件的设计中所必须的理论计算和相关强度校验,构建了采煤机滚筒总的指导思想,从而得出了该采煤机滚筒的优点是高效,经济,并且运行平稳的结论。

关键字 采煤机滚筒;结构;组成;结论

The design of shearer drum

Abstract

The shearer is a medium-low power electric haulage shearers mining medium-thick seam, for coal seam thickness , mining height ,coal bed pitch less than it, it can be used for hard coal mining.

This paper completed the design of shearer rocker arm, including the layout and three-dimensional modeling of speed reducer, it described the current status of domestic and international coal mining research and future development trends, the type of shearer, working principles and main components,it also introduced the specific structure of shearer rocker.

In the design process, completed the calculation and design of the reducer drive scheme and related components. First, completed the rocker reducer transmission ratio , speed and transfer power distribution calculation. Secondly, the completion of the design and check of five shafts and the shaft driving gears inside the rocker arm shell,simply introduced the assembly relationships and intensity checking of the planetary gear train. Thirdly, the completion of the selection and check the spline for connection. Finally, the three-dimensional modeling.

Key words: pneumatic manipulator; cylinder ;pneumatic loop ;degrees

滚筒采煤机的工作原理

双滚筒采煤机工作时,前滚筒割顶煤,后滚筒割底部煤并清理浮煤。(双滚筒采煤机的工作原理如图1.2所示)因此双滚筒采煤机沿工作面牵引一次,可以进一次刀;返回时,又可以进一刀,即采煤机往返一次进两次刀,这种采法称为双向采煤法。

目 录

摘要 1

Abstract 2

1.绪论 4

1.1课题的来源与研究的目的和意义 5

1.2采煤机概述 7

1.3滚筒采煤机的工作原理 7

1.4设计思路的提出 9

1.5本课题研究的内容 9

1.6 Solidworks设计基础 10

1.6.1草图绘制 11

1.6.2基准特征,参考几何体的创建 12

1.6.3拉伸、旋转、扫描和放样特征建 12

1.6.4工程图的设计 13

1.6.5装配设计 15

2.采煤机滚筒总体结构的设计 17

2.1采煤机滚筒的总体方案图 17

2.2采煤机滚筒的工作原理 18

2.3截齿的配置 18

2.4截齿的材料以及截齿的固定 19

2.5采煤机年产量的计算 19

3.各主要零部件强度的校核 19

3.1轮毂强度的校核与计算 20

3.2螺栓强度的校核计算 21

4.采煤机滚筒主要零件的三维建模 21

4.1轮毂的三维建模 21

4.2连接套的三维建模 21

4.3采煤机滚筒的三维建模 21

5.三维软件设计总结 26

结论 28

参考文献 29

致谢 30