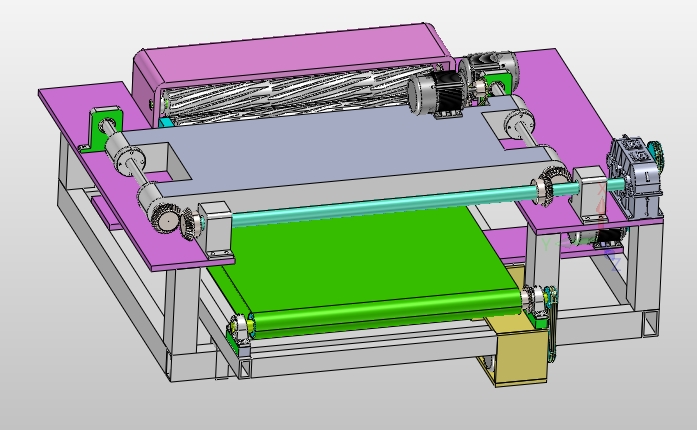

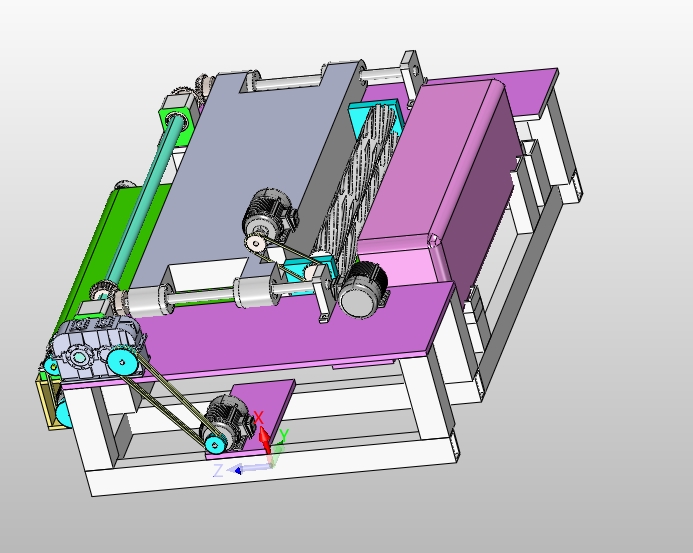

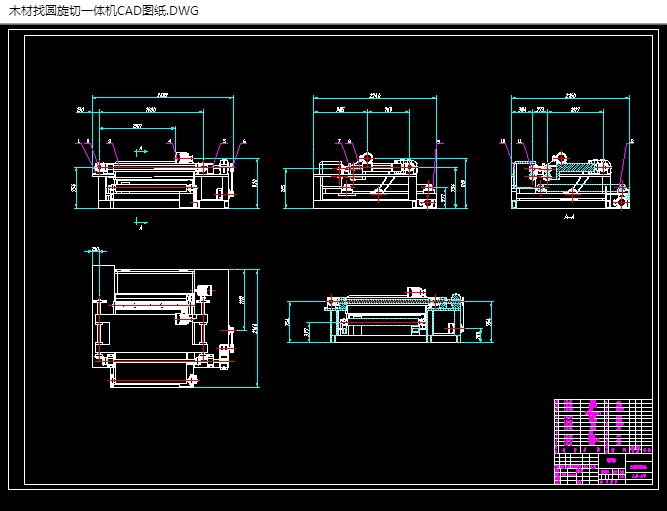

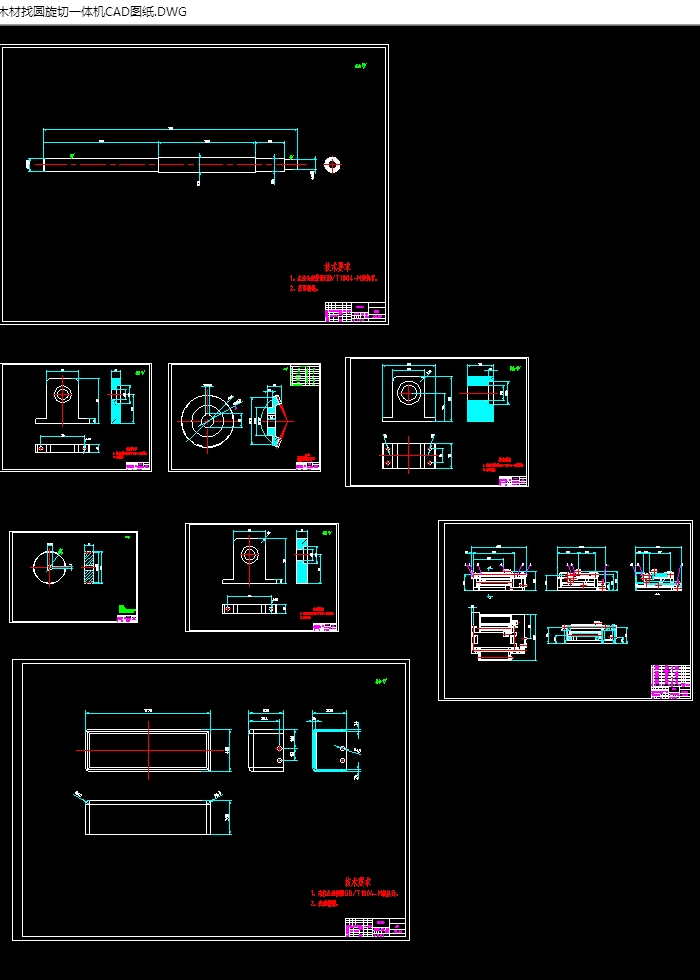

木材找圆旋切一体机的设计(含CAD图,SolidWorks,IGS三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

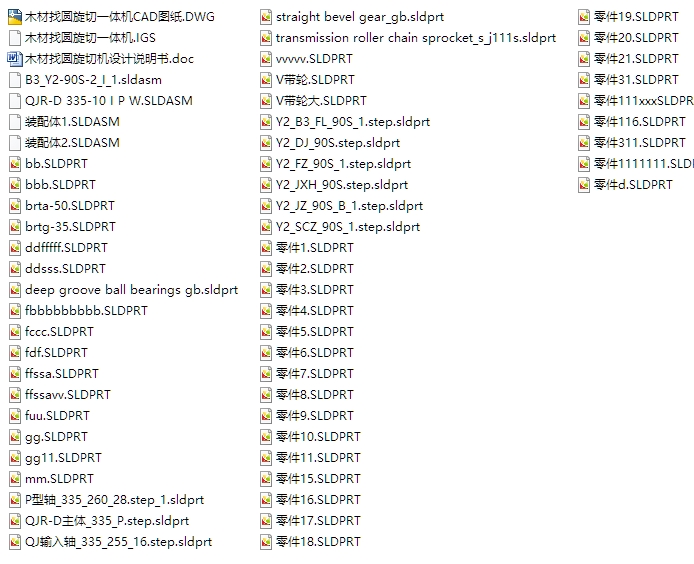

木材找圆旋切一体机的设计(含CAD图,SolidWorks,IGS三维图)(论文说明书12000字,CAD图纸8张,SolidWorks三维图,IGS通用三维格式)

摘 要

机械工业是一个国家的重要产业,机械工业的发展无时不刻都在影响着国家经济的发展,人类的进步离不开机械工业的发展。在全球经济发展的大环境下,中国各个行业被其他国家的先进技术影响的同时,越来越多的外国企业和品牌传播到中国已经成为现实。在新的市场需求的推动下,对木材找圆旋切一体机机进行改良和优化是当务之急。有大型木材找圆旋切设备生产企业对设备的安全指标的有着一定生产的严格要求。在生产设备的企业,充分考虑到在设备运行中可能出现的问题,从而减少噪声污染引起的振动或不当操作设备的现象等。国内木材找圆旋切一体机设备的研发及制造要与全球号召的高效经济、安全稳定主题保持一致。木材找圆旋切一体机的发展与人类社会的进步和科学技术的水平密切相关。

国内木材找圆旋切一体机设备的研发及制造要与全球号召的高效经济、找圆质量好,效率高等主题保持一致。近期对机械行业中木材找圆旋切一体机的使用情况进行了调查,发现在机械行业中,木材的使用非常普遍。自然而然在机械设备中它们的安装也非常频繁。传动的木材在没有自动找圆设备而需要人工找圆的情况下,找圆效率低下,劳动强度大,所以设计一个专用的木材找圆旋切一体机势在必行。

本文运用大学所学的知识,提出了木材找圆旋切一体机的结构组成、工作原理以及主要零部件的设计中所必须的理论计算和相关强度校验,构建了木材找圆旋切一体机总的指导思想,从而得出了该木材找圆旋切一体机的优点是高效,经济,并且找圆质量高,运行平稳的结论。

关键词:机械工业;木材找圆旋切一体机;效率;结论

Abstract

The environment of global economic development, China industries affected by other countries advanced technology at the same time, foreign enterprises and brand spread to more and more Chinese has become an opportunity. Cap pressing machine in industry through a variety of ways have been working with the relevant technology, and constantly improve their own strength and core competitiveness, and narrow the gap with developed countries. In the new market demand, update the sleeve pressing machine is a pressing matter of the moment. The production of pipe pressing machine equipment manufacturing enterprises to fully tap the potential of the market, vigorously develop the sleeves of large low cost pressing special machinery and equipment, plays a positive role in the evolution of automatic assembly, the assembly of mechanical equipment. There is a large pipe equipment on equipment safety index has strict requirements of production. In the production equipment of enterprises, give full consideration to the possible problems in the operation of the equipment, so as to reduce the noise pollution caused by vibration or improper operation of equipment phenomenon.

R & D and manufacturing of domestic pipe pressing equipment with global appeal, economic, security and stability of the theme consistent. Increase R & D and production pipe pressing equipment of new energy saving, efficient sleeve pressing machine is the trend of development of the industry, but also to meet the needs of the development of domestic infrastructure construction.Sleeve pressing plane is closely related with the development of society and the progress and the level of science and technology.

With the development of science and technology, interdisciplinary mutual infiltration, mutual exchanges between the various industry, extensive use of new structure, new materials, new technology, the sleeve pressing machine is large, efficient, reliable, energy saving,

Recently, the use of machinery industry, bearing and shaft sleeve shaft were investigated, found that the shaft, bearings and bushings in the machinery industry is one of the key parts. Come very naturally in the assembly of the installation is also very simple. In the installation if the use of artificial pressure with not only the labor intensity is too large and the size of each other is not easy to ensure the shaft, bearing and shaft sleeve, so the design of a special press be imperative. Graduation project this time is a tube axial compressive loading machine. This paper introduces the theoretical calculation to design sleeve pressing machine structure, working principle and main parts of the strength check and the advantages of the sleeve, pressing machine is efficient, economical, and high safety, stable operation. The overall plan is: the relative position of two axle sleeve on the plane, the motor reducer to provide power through belt drives the screw rod to rotate, and drives the head movement, a nut, a rotary motion of the linear motion of press. Block type safety clutch overload protection with teeth, pressure distribution in the corresponding position of the pipe after drilling through the drilling template.

Key word: pneumatic manipulator; cylinder; pneumatic loop; Fout degrees of freedom.

目 录

摘要 2

Abstract 3

第一章 绪论 4

1.1 课题的来源与研究的目的和意义 5

1.2 Solidworks设计基础 6

1.2.1 草图绘制 5

1.2.2 基准特征,参考几何体的创建 6

1.2.3 拉伸、旋转、扫描和放样特征建 7

1.2.4 工程图的设计 10

1.2.5 装配设计 11

第二章 木材找圆旋切一体机总体结构的设计 7

2.1 机械传动部分的设计计算 10

2.1.1往返驱动电机的选型计算 11

2.1.2V带传动的设计计算 11

2.1.3滚珠丝杆的选型计算 12

2.1.4直线导轨的选型计算设计计算 13

2.2牙嵌式离合器的工作原理 14

第三章 各主要零部件强度的校核 15

3.1轴承强度的校核与计算 18

3.2丝杆螺母强度的校核计算 20

第四章 木材找圆旋切一体机中主要零件的三维建模 24

4.1轴承座的三维建模 26

4.2电机的三维建模 28

4.3链轮的三维建模 30

4.4木材找圆旋切一体机的三维建模 32

第五章 三维软件设计总结 33

结论 34

致谢 35

参考文献 36