3500立方米拱顶储油罐设计(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

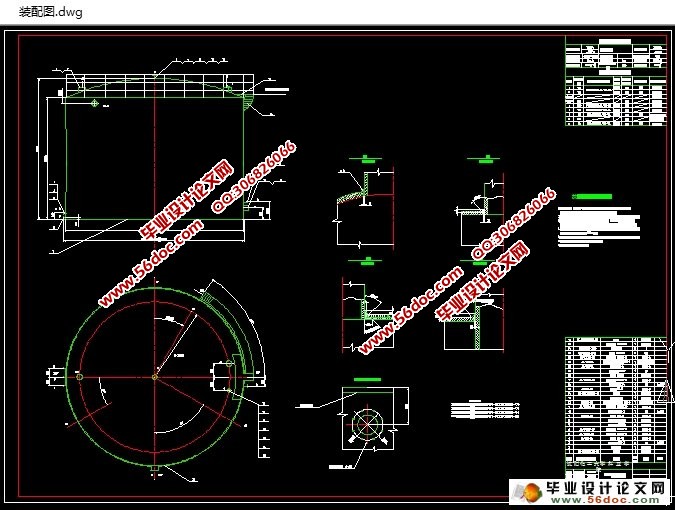

3500立方米拱顶储油罐设计(含CAD零件装配图)(设计说明书16800字,CAD图纸4张)

摘要

本设计的题目是3500立方米拱顶贮罐设计。贮罐主要应用于石油化工工业贮存石油及其产品以及其他液体化学产品。本设计设计的贮罐存储的液体为汽油。

本文的目的是对储油罐依据我国国情的发展趋势进行分析,进而由我国储罐发展趋势对3500m³拱顶储油罐设计。使以后我国使用的3500m³拱顶储油罐的设计方案更符合我国国情,改良后的3500m³储油罐有节约空间、建设时间短、施工简单和后期维修方便等优点让设计思路更符合我国的储油罐设计。

本设计的设计任务是:通过于查阅工具书及相关参考资料,了解贮罐,罐壁,罐顶,罐底和其他附件等各部件的结构和功能,并分析它们在各种载荷下的受力及各种应变,通过分步完成各部件的选材,设计计算和各种应力校核,最终完成一个公称容积为3500立方米的拱顶贮罐的设计,指明贮罐在工业应用中的注意事项并制定各种安全防护措旅来保证贮罐的安全使用。本设计的主要特点是:本贮罐的罐顶形式采用目前:最为普遍的拱顶,容积为3500立方米。

本设计设计过程包括:1.贮罐经济尺寸的选择;2.罐壁的设计;包括罐壁强度计算,贮罐风力稳定计算,贮罐的抗震设计,罐壁的结构设计和防腐蚀结构设计等。3.贮罐罐底的设计;4.贮罐罐顶的设计;5.贮罐附件的设计及选用;6.贮罐在工业应用中的安全及消防设施的设计选用等内容。

本设计共完成A1号图纸四张。包括3500立方米拱顶贮罐装配图一张,贮罐罐体图一张,贮罐罐壁图一张,贮罐罐底图一张。它们分别描绘了3500立方米贮液罐各个主要部件的组成与结构特点。

文字资料完成设计计算书一份,设计说明书一份,设计中所查参考的参考文献记载一份。

关键词: 油品贮罐; 强度计算; 盘梯; 罐顶

Abstract

The topic of this design is 3500 cubic meters of vault storage tank design. Oil storage tank is mainly used in petroleum and chemical ind-ustry and its products, and other liquid chemical products. The design of the storage tank to store liquid to gas.

The purpose of this article is to storage tanks according to the analysis of the development trend of China's national conditions, and then by our country development trend of tank design of 3500 m after vault storage tanks. Make use of 3500 m after vault storage tanks in China after design more accord with China's national conditions, mo-dified 3500 m after oil tank has a space saving, short construction time, construction is simple and convenient maintenance for late design more in line with the oil tank design of our country.

Design task of this design is : through the consult reference books and related resources, understand the storage tank, the tank wall, roof, the tank bottom and othe raccessories and so on various parts of the structure and function, and analyze them in a variety of stress and st-rain under the load, through step by step to complete the select mater-ial of each parts design calculation and various stress checking, finally completed a nominal capacity of 3500 cubic meters of the design of t-he vault storage tank, storage tank in the matters of attention in the industrial applications are pointed out and formulate various safety pr-otection measures used to ensure the safety of the tank. The design of the main features are: the form of storage tank roof adopts at present: the mos t common vault, the volume of 3500 cubic meters.

This design including design process: 1. The tank size economic choice; 2. The design of the tank wall; Wind stability calculation incl-uding tank wall strength calculation, storage tank, storage tank of the seismic design, the structure of tank wall design, design of anticorrosive structure and so on. 3. The design of the storage tank bottom; 4. The design of tank roof; 5. The design of tank accessories and selection; 6. Storage tank in the design of the industrial application of the security and fire control facilities selection , etc.

This design completed A 1 drawing number four. Including 3500 cubic meters a vault storage tank assembly drawing, figure a storage tank, storage tank wall map, a storage tank a reproduction. Respectively depicts 3500 cubic meters of water storage tank is the main part of composition and structural characteristics. A written materials to complete the literature review, a design calculation , a design specification, ch-eck the reference in the design of a reference document.

Key words: oil tank; Strength calculation; winder; dome tank

目 录

第一章储罐设计计算 1

1.1 储罐经济尺寸的选择 1

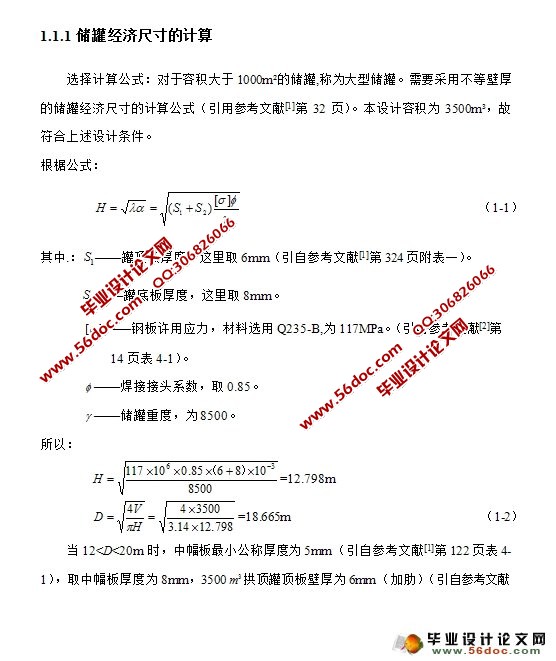

1.1.1 储罐经济尺寸的计算 1

1.1.2 载荷的计算 2

1.2 罐壁设计 3

1.2.1 罐壁的强度计算 3

1.2.2 罐壁下节点边缘应力的校核 4

1.3 储罐的风力计算 8

1.3.1 抗风圈计算 8

1.3.2 加强圈计算 8

1.4 储罐的抗震设计 9

1.5罐壁结构设计 11

1.5.1 截面与联接形式设计 11

1.5.2 圈板宽度计算 11

1.5.3 包边角钢设计 11

1.5.4 罐壁开孔补强计算 11

1.5.5 储罐进出口管结构设计 12

1.5.6 其他结构设计 12

1.6 防腐蚀结构设计 13

1.7 罐底设计 13

1.7.1 罐底的应力计算 13

1.7.2 罐底结构设计 14

1.8 罐顶设计(拱顶罐) 15

1.8.1 结构 16

1.8.2 顶板厚度的选取 17

1.8.3 拱顶球壳的稳定验算 18

1.9盘梯与平台设计 20

1.9.1 盘梯与平台的计算 20

1.9.2 选型原则 22

1.9.3 注意事项 22

1.10 储罐附件设计与选用 23

1.10.1 概述 23

1.10.2 常用附件 23

1.11 安全及消防设计 25

1.11.1 概述 25

1.11.2消防设施 25

1.11.3其他安全设施 26

第二章设计说明书 28

2.1 储罐的制造 28

2.1.1 底板的制造、组装与焊接 28

2.1.2 壁板的制造与组装焊接 29

2.1.3 固定顶储罐顶板制造与组装焊接 30

2.1.4 注意事项 31

2.2 储罐的安装施工 31

2.3 储罐的验收 32

2.3.1 储罐几何尺寸公差 32

2.3.2 焊接的检验 32

2.3.3 焊缝返修 33

2.3.4 罐底严密性试验 34

2.3.5 罐壁、罐顶的严密性和强度试验 34

2.4 防腐蚀 34

2.5 储罐的使用注意事项 34

参考文献 36

致谢 37