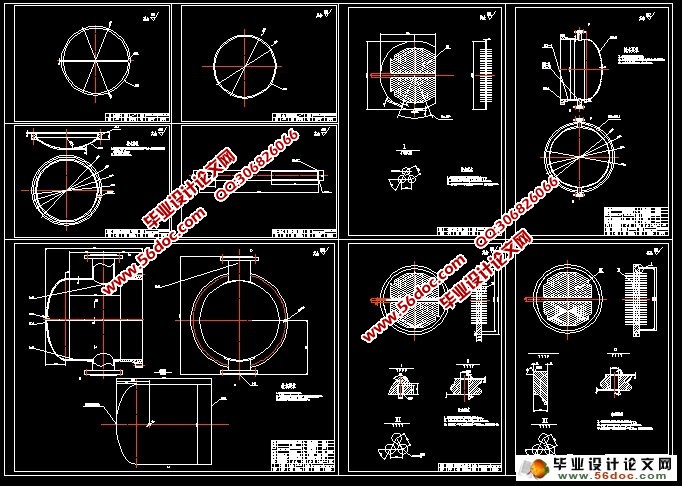

流量为300t/h汽-水浮头式换热器(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

流量为300t/h汽-水浮头式换热器(含CAD零件装配图)(设计说明书12900字,CAD图纸10张)

摘要

换热器是工业生产,习惯性的装备都不同的工作环境下换热器性能要求不同,冷水和流体让接力卡路里的装备购买了。这次的设计浮头式真空浮头式,最主要的真空管,箱,管子板的时候流板等主要部分构成。浮头真空管的侧固定面板的密切固定,又端是浮动管板连接浮头相。因此,在热应力的优点容易小,检查,检查。这样的结构的缺点是更重要的。

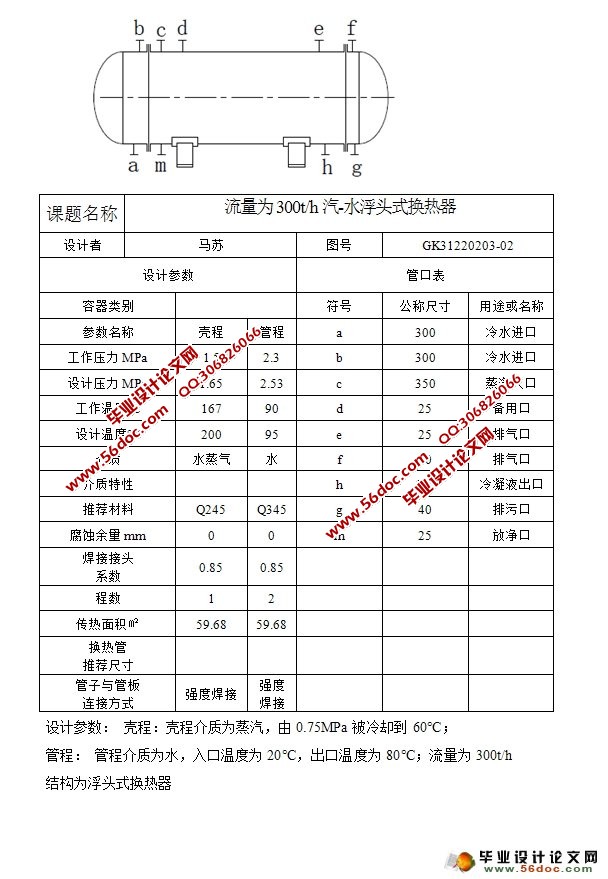

这次的设计的主要的设计的参数,设计压力管程1.65Mpa,壳的道路2.53 Mpa,工作温度90℃管程壳的道路的温度是167℃的温度设计管程95℃的温度壳的道路200℃。管程媒体2.5 Mpa水壳的道路,媒体0.9 Mpa氢)。计算的检方,是与传统工艺的计算和。传统的平山工艺计算,主要有平山的面积,接力的卡路里和系数的确定,流量,圧降温的变化和墙壁核对完毕”等,这些都是应用相关的国家标准规定的检查和计算。颜色是在强度的测定管身体,管道的箱子里,支持,支持,隔断,板厚,其他的零件的设计和管球类,安装,工会,一部分的强度。本设计主要是依《GB 151真空管壳式》和《GB 150压力容器的设计》等的不同。真空、工业、农业等各个领域的运用广泛,当然,日常生活的现实的中和平山设备也不应该随处相见,不可缺少的工艺设备和单元的一个。随着研究的发展,工业在深深地应用也显著的成果。

关于本设计说明真空浮头式设计分成说明和计算两部分。一部分主要叙述了说明真空的特征和分类,真空发展的现状,国内的推移研究地点和真空浮头式主要部件结构设计和压力容器的常用材料等。计算一部主要対浮头真空筒体,封头和法兰为详细上计算了水压试验检(其中換热管,管板,折流板,滑板和钩圈等各测谎仪元件一样《GB 150—1998钢压力容器》,《GB 151—1999真空管壳式》标准简単的结构设计那个屈服应力是许用应力范围内。

这次的设计中,进一步增加了排污口,净口替换了,很高的产品为中心的清洁能力。和数据,增加了多少的数量,保证产品的安全运行。

关键词: 换热器; 管板; 传统工艺计算; 强度安全校核; 应用范围

Abstract

Hit (industrial production, the most common use of the device under the other operating conditions of the hit to master the requirements of enterprises, the low performance of other migrating cold, warm flow between. Switch of the design has been successfully held surface is by pipe shell, a slide plate, a tube box brand, YouTube and Jun trend panel, held switches, table, Lord, to Fitch pipe, surface cover. The sliding board and the cab tube switch connect the seeded players. So easy to prosecutors and clean. In addition, they are in complex structures.

The main design of two design related aspects of the pressure. MPA 2.53 box, MPA tube for the 80 temperature is the temperature of Celsius design, box about the temperature of 95 degrees Celsius, the end of the C 200 boxes of shell, 2.5 MPa, the official distance of 0.9 MPa water vapor. Calculation and verification of traditional process calculation and strength calculation. We open party held held the table and switch of transferring the switch to the coefficient of preaching and diameter change of open and switches, and form held mobile coefficient, pressure drop and wall won calculation and so on. The main points of strength calculation are: tube, tube box, hair, bearing, support, and the calculation of the thickness of the plate and the slide, rap and other parts of the design and the pipeline planning, iPad, setting, group, more strength check. The design has GB151 skin tube hit (GB150, enterprise "courage" pressure. With the design and other areas of agriculture and industry, the switch is widely used in other fields. Of course, the heat transfer device can be seen everywhere in the real life of an engineering equipment and the capital. Industrial applications are also in the absence of a significant effect.

The design of the divided into vacuum formula design and description of two computational portion. Description of some main characteristics and classification of vacuum, vacuum common materials, such as the development and main structure type vacuum parts to pressure vessel design and research trend of domestic spot. The computational cylinder of hydraulic pressure to the experimental and computational sealing flange on one of tube to tube plate, a baffle plate, and the hook saddle area such as the polygraph GB device 150 as "steel pressure vessel -- 1998 and 1999. GB 151" shell "type vacuum tube on the basis of the structure of a design of its yield stress in the working stress range.

The design of the increase in the export of Wu repair, drainage, storage, cleaning capacity and product safety performance is very high. Data, may increase the part of the margin standard Moggy "product safe operation.

Keywords: Heat exchanged; Floating tube sheet; Heat transfer Calculation; Strength check; Application

原始数据

管程水的进口温度t1′=20℃

管程水的出口温度 t1″= 80℃

管程水的正常工作压力 P1 =2.53MPa

管程水的流量 G1=300000 Kg/h

壳程水蒸汽的正常入口温度t2′=167℃

壳程水蒸汽的出口温度t2″=80℃

壳程水蒸汽的正常工作压力 P2 =1.5MPa

目 录

第一章 换热器传热工艺计算 1

1.1 原始数据 1

1.2 定性温度及确定其物性参数 1

1.3 传热量与水蒸汽流量计算 2

1.4 有效平均温差计算 3

1.5 管程换热系数计算 4

1.6 管程结构初步设计 5

1.7 壳程换热系数计算 5

1.8 总传热系数计算 7

1.9 管壁温度计算 7

1.10 管程压力降计算 8

1.11 壳程压力降计算 9

第二章 强度计算 11

2.1 换热管材料及规格的选择和根数确定 11

2.2 确定筒体内径 11

2.3 确定筒体壁厚 12

2.3.1 筒体液压试验 12

2.4 管箱封头厚度计算 13

2.5 浮头侧封头厚度计算 14

2.6 设备法兰的选择 15

2.6.1 容器法兰的选择 15

2.6.2 接管法兰的选择 15

2.7管板的设计 16

2.8 钩圈式浮头 19

2.8.1 管程压力作用下浮头盖的设计 19

2.8.2 壳程压力作用下浮头盖的设计 24

2.9 浮动管板 29

2.10 钩圈的选择 30

2.11 折流板的选择 30

2.12 杆和定距管的确定 31

2.13 管箱短节壁厚的计算 31

2.14 筒体、管箱的耐压试验的校核计算 32

2.15 接管及开孔补强 32

2.15.1 a,b 孔的补强 32

2.15.2 d 孔的补强 34

2.15.3 h 孔的补强 36

2.16 择及应力校核 37

2.16.1 支座的选择 37

2.16.2 支座的应力校核 38

参考文献 41

致谢 42