流量为200t/h冷凝器的设计(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

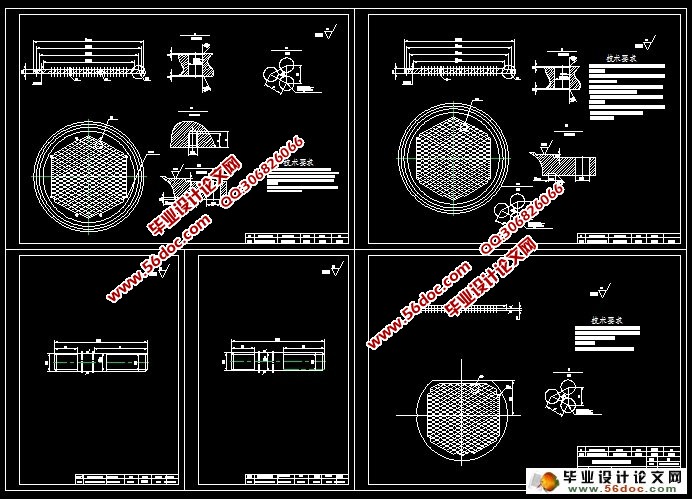

流量为200t/h冷凝器的设计(含CAD零件装配图)(设计说明书10500字,CAD图纸8张)

摘要

冷凝器是使用范围很广的一种化工设备,属于换热器的一种。本设计任务主要是根据已知条件选择采用固定管板式换热器的设计,固定管板式换热器的优点是锻件使用少,造价低;传热面积比浮头式换热器大20%到30%且旁路渗流小。

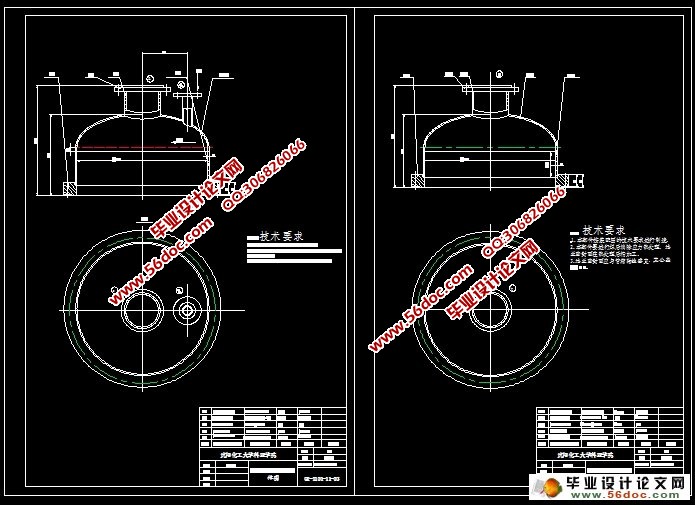

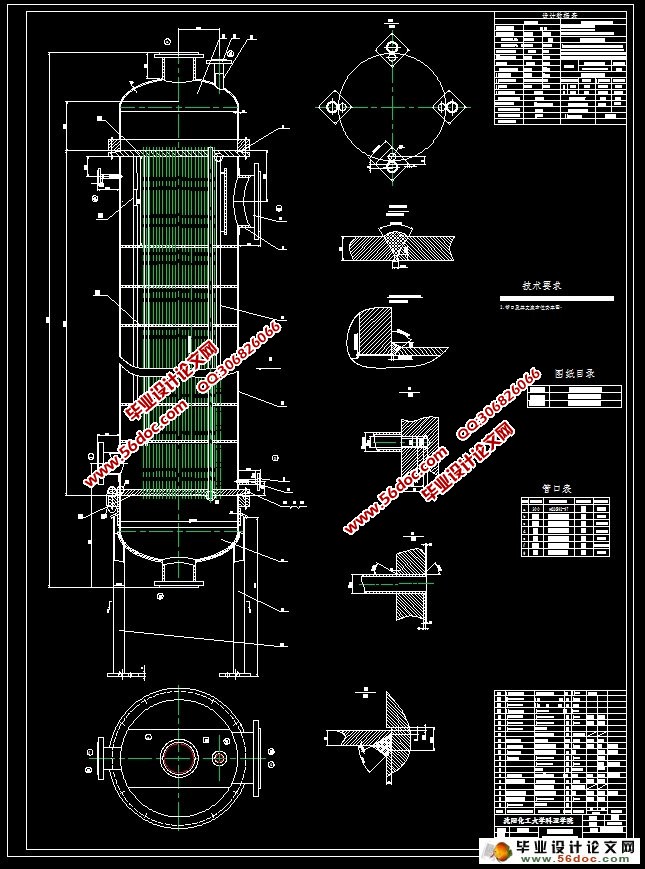

本台换热器主要完成的是水蒸气-水之间的热量交换,首先根据给出的设计温度和设计压力来确定设备的结构形式以及壳程和管程的材料,然后根据物料性质和传热面积来确定换热管的材料,尺寸,根数。,设计压力为管程2.31MPa,壳程0.935MPa,工作温度管程50℃,壳程130℃,设计温度管程80℃,壳程140℃,传热面积为256 ,采用Φ25×2.5×3000的无缝钢管换热,则可计算出622根换热管,D=1200mm的圆筒根据换热管的根数确定换热管的排列,并根据换热管的排列和长度来确定筒体直径以及折流板的选择。通过对容器的内径和内外压的计算来确定壳体和封头的厚度并进行强度校核。然后是对换热器各部件的零部件的强度设计,有法兰的选择和设计计算与校核,钩圈及浮头法兰的设计计算与校核和管子拉脱力的计算。还包括管板的结构设计、防冲挡板、滑道结构的设计以及支座设计。结构设计中的标准件可以参照国家标准根据设计条件直接选取;非标准件,设计完结构后必须进行相应的应力校核。

管板与换热管的连接方式为焊接,因管板上的应力较多,且内外温度有一定的差值,因此,对管板强度的校核是一个重点,也是一个难点..

关键词: 换热器; 强度设计; 结构设计

Abstract

The condenser is a kind of chemical equipment which is widely used, and belongs to a kind of heat exchanger.. The design task is mainly according to the known conditions to choose the design of fixed tube plate heat exchanger, the advantages of fixed tube plate heat exchanger is forging used less, low cost; heat transfer area ratio of floating head type for heat exchanger is 20% to 30% and a bypass flow small.

The heat exchanger is mainly completed is between water vapor and water heat exchange, first of all according to the given design temperature and pressure to determine structure of equipment and the shell side and tube side material, and then according to the nature of the material and the heat transfer area to determine the heat exchange tube materials, dimensions, number of roots. And design pressure for tube side 2.31MPa, shell 0.935MPa, the working temperature of the tube process 50 DEG C, 130 DEG C shell, design temperature tube process at a temperature of 80 DEG C, shell and 140 DEG C, heat transfer area for 256m2. The phi 25 x 2.5 x 3000 seamless steel pipe heat exchanger can be calculated 622 heat exchange tube, D=1200mm cylindrical root according to determine the root number of heat exchange tube heat exchanger tube arrangement and according to the arrangement and length of heat exchange tube to determine cylinder diameter and baffle the choice. Determine the thickness of the shell and the head and carry out the intensity verification by calculating the inner diameter and the internal pressure of the container.. Then the strength design of components of the various components of the heat exchanger, flange design, selection and calculation and checking, hook and loop and floating head flange design calculation and checking of the pipe and pull off force calculation. Also includes a tube plate structure design, anti scour baffle, slideway structure design and the design of support. The standard parts in the structure design can be selected directly according to the national standards; the non standard parts must be checked for the corresponding stress after the design of the structure.

Tube plate and tube heat exchanger and the connection mode of welding, tube plate more stress, and the temperature inside and outside have certain difference. Therefore, on the tube sheet strength check is a key and a difficulties.

Keywords: Heat exchanger; Strength design; Structure design

目 录

第一章传统工艺计算 2

1.1 工艺计算 2

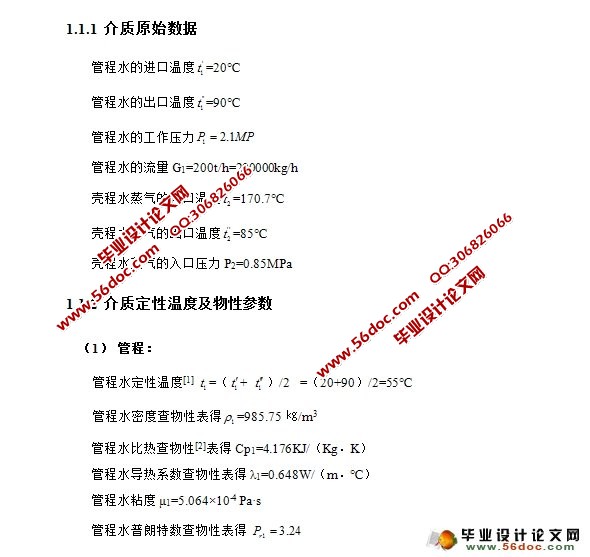

1.1.1 介质原始数据 2

1.1.2 介质定性温度及物性参数 2

1.2 传热量与水蒸汽流量计算 3

1.3 有效平均温差计算 4

1.4 管程换热系数计算 5

1.5 管程结构初步设计 6

1.6 壳程换热系数计算 7

1.7 总传热系数计算 8

1.8 管壁温度计算 8

1.9 管程压力降计算 9

1.10 壳程压力降计算 10

第二章强度计算 12

2.1 结构设计说明书 12

2.1.1 换热管材料及规格的选择和根数的确定 12

2.1.2 布管方式的选择 12

2.1.3 筒体内径的确定 12

2.1.4 筒体壁厚的确定 13

2.1.5 封头形式的确定 13

2.1.6 管箱短节壁厚计算 14

2.1.7 容器法兰的选择 14

2.1.8 管板尺寸的确定及强度计算 15

2.1.9 是否安装膨胀节的判定 27

2.1.10 各管孔接管及其法兰的选择 27

2.1.11 设备法兰的选择 30

2.1.12 拉杆和定距管的确定 32

2.1.13 开孔补强计算 33

2.2 筒体管箱耐压试验的应力校核计算 35

2.2.1 筒体核算 35

2.2.2 支座的选择及应力校核 35

2.2.3 耳座的应力校核 36

参考文献 39

致 谢 40