板(框)类制品叠层式注射模具设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

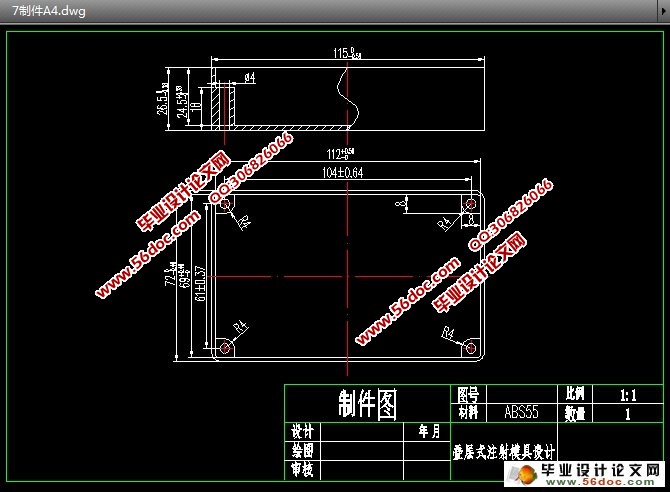

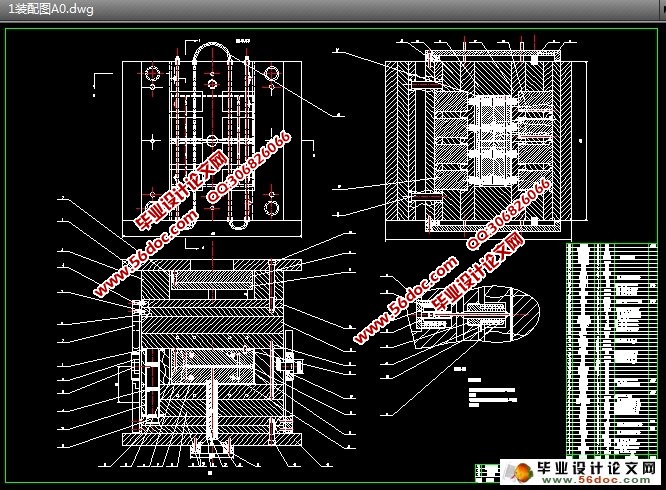

板(框)类制品叠层式注射模具设计(含CAD零件图装配图)(设计说明书10900字,外文翻译,CAD图7张)

摘要

本论文设计了仪器外壳的叠层式热流道模具结构。该模具有2层,每层8个型腔,一次可成型16个产品,该模具是普通注射成型产量的2倍,大大提高生产力。本次模具设计采用的是无流道凝料浇筑系统,不考虑浇道的凝料脱出,减少了分型面,并缩短了成型周期,降低了整个生产成本。而且还采用了齿轮齿条开模机构,在确保俩层型腔同时开模又比较经济。使热流道板的热胀变形问题和浇口的平衡问题有一个很好的解决,基本确保同时充模和充模的稳定可靠性。该模具还采用闭合式喷嘴和闭合式主流道杯,解决了浇口和主流道始端的流涎问题,它采用热电偶控制喷嘴温度和流道板温度。在设计中,为减少热传导热损失。在流道板和型腔板之间采用空气隔热,并加隔热垫,从而降低模具和流道板之间的接触面积,并发挥了支撑热流道板的作用。喷嘴和主流道杯均采用隔热套隔热。

关键词 热流道;叠层式模具;浇口平衡;防流涎

Abstract

This design introduces the mould structure of instrument of outer cover, which has piles of type and thermal current dishes. The mould has 2 layers of types, 8 for each layer, which can shape 16 products for once, the mould can produce 2 times of products ordinary inject shaping, and it boosts productivity greatly . The mould uses a thermal current dish of congeal material , without consideration of the deviatation of water dish congeal material, which has reduced dividing type, and shortened shaping cycle. And it has reduced the cost of the production on the whole. The mould which is economic adopts a gear and rack to turn on , making sure the two types of the mould turning on at the same time. The mould gives a good settlement of the expansion problem of the board of the thermal current dishes and the balance problem of runner, guaranting to fill the mould steadily and basically making sure the mould filling at the same time. The mould adopts the spray nozzle of closing type and the cup of mainstream dishes, solve the saliva problem of runner and the top shed of mainstream dishes, and it adopts the electric thermocouple to control the temperature of the spray nozzle and the flow dishes board. In the design, for reducing losing heat of the heat-conduction. Between the flow dishes board and the mould board, there is air to against heat, there are against heat cushions to against heat ,which reduces the area of contact between the mould board and the flow dishes and plays a role of supporting of the board of the thermal current. The spray nozzles and the cup of the mainstream dishes have heat insulation set.

Keywords Thermal current one One pile of types mould Balance the runner Prevent saliva flows

产品使用要求

该产品是一种仪表外盖,因需从外面能看到里面,故要求材料透明外表面光洁度R 小于0.5µm。另外还要求外盖的绝缘性能良好,并且由于外盖是暴露在外面的,所以要求材料的抗腐蚀能力较强。

产品材料

根据上述使用要求,经查表选用塑料ABS55。

目 录

摘要 II

Abstract III

1 绪论 1

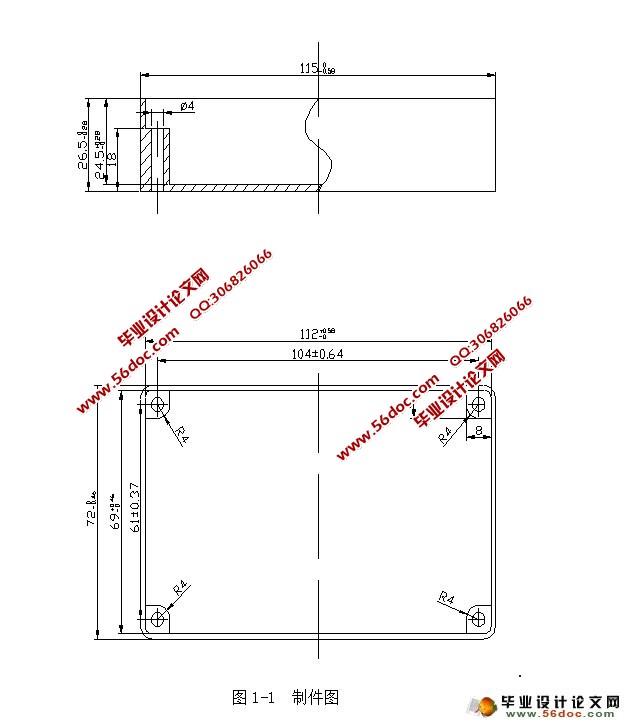

2 制品设计 3

2.1制件图 3

2.2产品使用要求 4

2.3产品材料 4

3 工艺分析 5

3.1 塑料特性 5

3.2 塑料的注射工艺条件 5

3.3 塑件使用材料的工艺分析 6

4选择设备 7

5模具设计 8

5.1 模具结构设计 8

5.1.1 选择分型面 8

5.1.2 布置型腔 8

5.1.3 确定成型零部件结构 9

5.1.4 浇注系统结构设计 9

5.1.5 开模机构设计 10

5.1.6 脱模机构设计 11

5.1.7 温控系统设计 11

5.2主要零部件尺寸计算 11

5.2.1 成型零部件尺寸计算 11

5.2.2 确定模具各部分结构尺寸 17

5.2.3 浇注系统计算 18

5.2.4 冷却系统计算 21

5.2.5 推出机构计算 25

5.3 校核 28

5.3.1 模具与注射机关系校核 28

5.3.2 物料流程与流动比校核 29

结论 30

致谢 31

参考文献 32