电子产品的端盖Φ20顶盖冲压工艺及模具设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

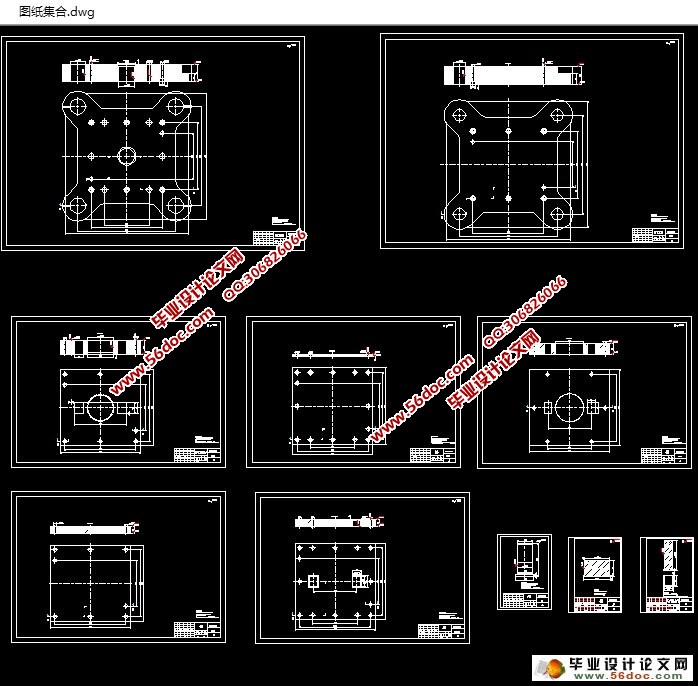

电子产品的端盖Φ20顶盖冲压工艺及模具设计(含CAD图)(文献综述,设计说明书10000字,CAD图11张)

摘 要

拉深是冲压几个基本工序的一种,它是利用模具在压力机的作用下,将平板配料冲制成筒形开口零件的加工方法。它不仅仅可以加工旋转体零件,例如水壶,还可以加工盒型零件,例如饭盒,还可以加工形状复杂的零件,例如汽车车身覆盖板。但是,冲压加工出来的制件精度都比较低。只有发展我国的模具制造水平以及理论研究,才能准确的确定拉深工艺参数和模具工作的几何形状和尺寸,解决各种可能在拉深过程中出现问题。

本零件为电子产品的端盖,冲压工艺的选择是通过查找学习的书籍和对产品的观察和对比的基础上进行的;冲压模具的选择是通过多方面选择的,包括是否容易制造,经济性是否高等。该电子零件的计算数据可能与实际生产的零件有所出入,不过冲压模具的设计都参考了几本书籍完成的。

关键词:冲压; 拉深模; 冲孔;弯曲; 筒形件

ABSTRACT

Deep drawing is a kind of punching a few basic working procedure, it is to use under the action of the mold in the press, the slab opening ingredients rushed into cylindrical parts processing method. It not only can the processing of revolving parts, such as kettle, can also processing box type parts, such as lunch box, you can also processing complicated shape parts, such as the automobile body cover plate. However, stamping processing of precision parts are relatively low. In general, deep drawing parts size accuracy under IT13, unfavorable above IT11. Only development level of mould manufacturing and theory research in China, in order to accurately determine the deep drawing process parameters and die working geometric shapes and sizes, solve all kinds of possible problems in the process of deep drawing.

This part for the end cover of electronic products, stamping process choice is to check the related information and the product shape is conducted on the basis of careful analysis; Were considered in the choice of stamping die is in economy, parts stamping manufacturability and complexity on the basis of many factors. The calculation data of electronic parts may differ with the actual production of parts, but the design of the stamping die reference several books.

Keywords: stamping; deep drawing die,; punching,; bending; cylindrical part

目 录

1. 零件及工艺性分析---------------------------------------------- 6

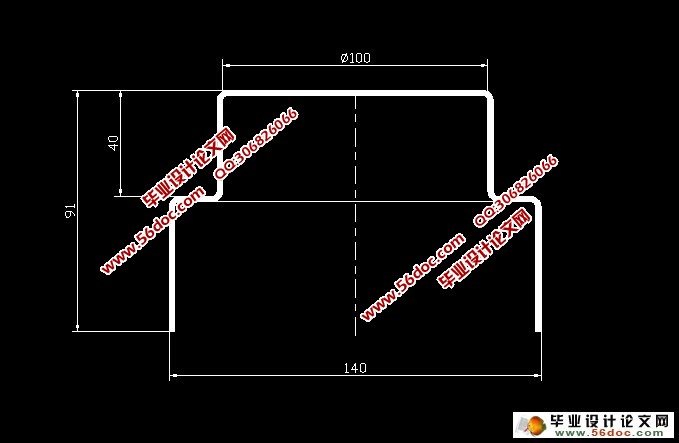

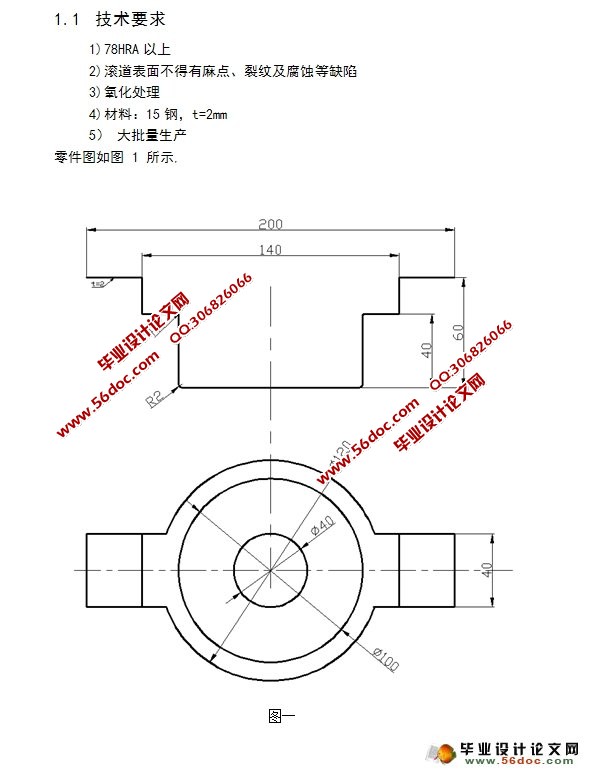

1.1 技术要求--------------------------------------------------- 6

1.2 读产品图,分析冲压工艺性----------------------------------- 7

2. 分析计算确定工艺方案------------------------------------------ 7

2.1 计算毛坯尺寸----------------------------------------------- 7

2.2 判断拉深次数----------------------------------------------- 7

2.3 判断是否要用压边圈----------------------------------------- 8

2.4 确定工艺方案----------------------------------------------- 9

3. 主要工艺参数的计算-------------------------------------------- 9

3.1 确定排样、裁板方案----------------------------------------- 9

3.2 拉深凸、凹模圆角半径-------------------------------------- 11

4. 计算工艺力-------------------------------------------------- 11

4.1落料力------------------------------------------------------ 11

4.2卸料力------------------------------------------------------ 12

4.3拉深力------------------------------------------------------ 12

4.4压边力-------------------------------------------------------12

4.5冲孔力-------------------------------------------------------12

5. 冲压设备的选择--------------------------------------------------14

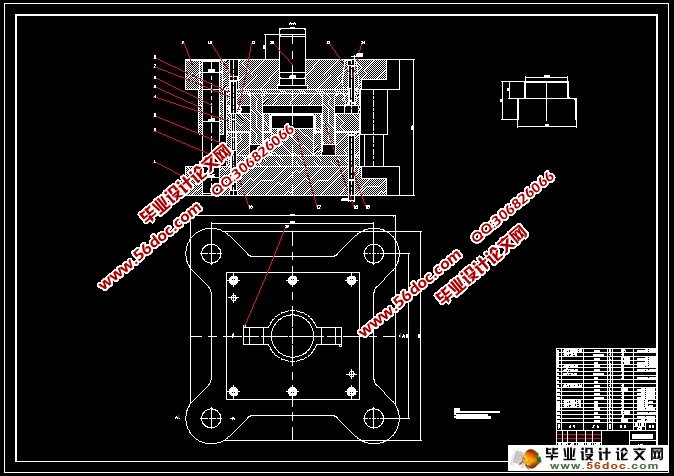

6. 模具结构的设计------------------------------------------------- 15

6.1 落料凸、凹模尺寸计算--------------------------------------- 15

6.2 拉深凸、凹模尺寸计算--------------------------------------- 17

6.3 冲孔凸、凹模尺寸计算--------------------------------------- 18

6.4 下凸凹模强度、刚度校核------------------------------------- 19

7. 选用模架、确定闭合高度及总体尺寸------------------------------ 20

8. 计算模具的其他尺寸-------------------------------------------- 21

8.1 弯曲凸模--------------------------------------------------- 21

8.2 凹模板的设计---------------------------------------------- 22

8.3定位块的设计----------------------------------------------- 23

8.4 模具导柱的设计-------------------------------------------- 24

8.5 模具导套的设计--------------------------------------------- 25

8.6 顶料弹簧---------------------------------------------------- 25

8.7 顶料橡胶---------------------------------------------------- 27

9. 编制冲压工作零件工艺卡--------------------------------------- 29

9.1 冲孔凸模的选材、热处理及加工工艺过程----------------------- 29

9.2 上凸凹模的选材、热处理及加工工艺过程----------------------- 29

9.3 下凸凹模的选材、热处理及加工工艺过程----------------------- 29

9.4 落料凹模的选材、热处理及加工工艺过程----------------------- 29

9.5 卸料板的选材、热处理及加工工艺过程------------------------- 30

9.6 模座的选材、热处理及加工工艺过程--------------------------- 30

9.7 导柱、导套的选材、热处理及加工工艺过程--------------------- 31

10. 模具装配图--------------------------------------------------- 32

结论--------------------------------------------------------------33

致谢--------------------------------------------------------------34

参考文献----------------------------------------------------------35