螺旋摆动液压缸设计(含CAD零件图和装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

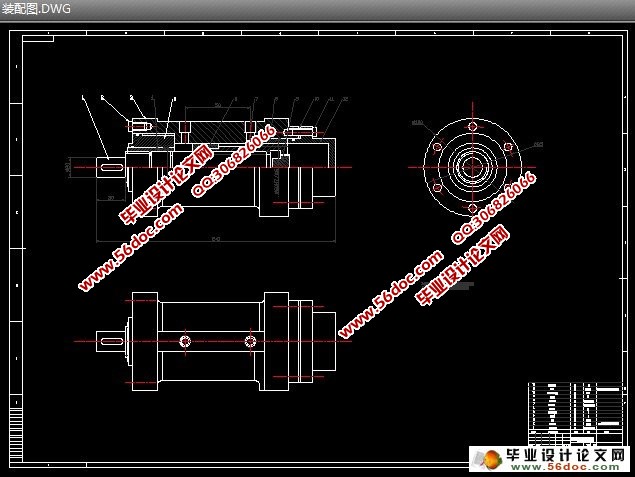

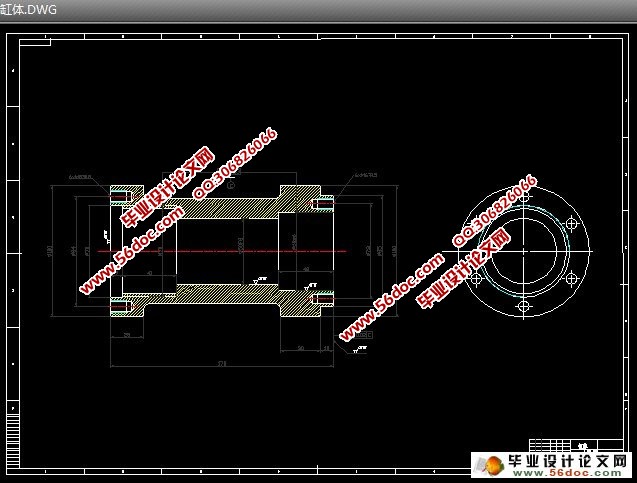

螺旋摆动液压缸设计(含CAD零件图和装配图)(任务书,开题报告,毕业论文说明书23800字,CAD图纸4张)

[摘要] DA-H40螺旋摆动液压缸相对于传统的叶片式、齿轮齿条式、链条链轮式摆动液压缸,由于其采用了特有的双螺旋副结构,具有摆动角度大、承载性能高、结构紧凑、传动效率高等优点,广泛应用在工程机械、建筑机械、农林机械等设备上。由于国外对此技术的垄断,国内在这方面的研究起步较晚,设计制造重载、高压、高可靠性、高定位精度、长寿命的螺旋摆动液压缸技术,国内尚未完全掌握。因此,从结构特性、虚拟样机技术及流体润滑方面研究,获得较优的结构参数,具有重要的理论和工程应用价值。论文主要进行了以下研究工作:

应用两级梯形螺旋副结构设计了摆动液压缸,进行了螺旋副的承载性能分析。确定了两级螺旋副的相关结构参数:螺旋升角、螺距、导程、牙型角、公称直径、工作长度等。进行了螺旋摆动液压缸整体结构的三维虚拟装配、各零件间的干涉检验。

揭示了空心螺杆与固定螺母间不同周向间隙和不同螺距油膜的压力、速度、温度分布规律。研究了周向间隙、液压油粘度、螺距、旋合长度对油膜的承载性能及油腔内泄漏的影响。以承载性能及传动效率为目标,获得了较好的螺旋副周向间隙值、螺距值、旋合长度值和液压油粘度值。揭示了两级螺旋副的结构参数和工艺参数对螺旋摆动液压缸传动效率的影响规律。建立了螺旋摆动液压缸传动的总效率模型。

[关键词] 螺旋式;摆动液压缸;流体动力润滑;间隙

DA - H 40 spiral swing hydraulic cylinder design

[Abstract ] Spiral swing hydraulic cylinder compared with traditional vane, gear and rack type, the chain sprocket type swing hydraulic cylinder, because of its double helix structure, using the swing Angle is big, high performance, compact structure, high transmission efficiency, etc. Due to foreign technology monopoly, domestic started relatively late in this study, design and manufacture of overload, high pressure, high reliability, high precision, long life of spiral swing hydraulic cylinder technology, domestic has not been fully mastered. Therefore, from the structural characteristics, the virtual prototype technology and fluid lubrication research, to obtain the optimal structure parameters, is of important theoretical and engineering application value. Thesis mainly conducted the following research work:

Application of two levels of trapezoidal screw pair of swinging hydraulic cylinder structure design, the bearing capacity of screw pair analysis. Determine the related structural parameters of two-stage screw pair: lead, helix Angle, pitch, tooth type Angle, nominal diameter, length etc. The whole structure of the spiral swing hydraulic cylinder of 3 d virtual assembly, interference between the various parts of inspection.

Reveals the hollow screw with a fixed nut and different circumferential clearance between different pitch of the oil film pressure, speed, temperature distribution. Bearing performance and transmission efficiency as the goal, to get the better screw pair of circumferential clearance value, pitch, screw length value and the hydraulic oil viscosity values. Reveals the two levels of structure parameters and technological parameters of screw pair to screw the influence law of swinging hydraulic cylinder transmission efficiency. The establishment of a spiral swing hydraulic cylinder drive total efficiency model.

[Keywords] spiral swing hydraulic cylinder, hydrodynamic lubrication, clearance

设计应完成的主要内容

螺旋摆动液压缸的概况;

螺旋摆动液压缸结构方案;

螺旋摆动液压缸基本参数的设计计算;

螺旋摆动液压缸结构设计;

重点研究的关键问题

按照设计要求螺旋摆动液压缸的性能,合理地确定基本结构参数。

螺旋摆动液压缸结构强度设计与校核。

螺旋摆动液压缸密封、缓冲、稳定性等问题的解决。

目 录

任务书 Ⅰ

开题报告 Ⅱ

指导教师审查意见 Ⅲ

评阅教师评语 Ⅳ

答辩会议记录 Ⅴ

中文摘要 Ⅵ

外文摘要 Ⅶ

前言 1

1 选题背景 2

1.1 研究目的和意义 2

1.2 摆动液压缸的结构形式 3

2 国内外螺旋摆动液压缸的发展趋势 5

2.1 课题研究的目的 6

3 液压缸的总体设计 7

3.1 设计思想 7

3.2 液压缸的分类 7

3.3 双螺旋副摆动液压缸的工作原理分析 9

3.4 螺旋摆动液压缸关键部件-----双螺旋副的结构设计 10

3.5 螺旋摆动液压缸的密封装置设计 19

3.6 螺旋摆动液压缸的整体结构设计 20

3.7 本章小结 23

4 螺旋摆动液压缸的传动效率研究 24

4.1 螺旋摆动液压缸传动效率的影响因素分析 24

4.2 螺旋摆动液压缸结构参数与材料参数的设计总结 26

5 总结 28

参考文献 29

致 谢 30