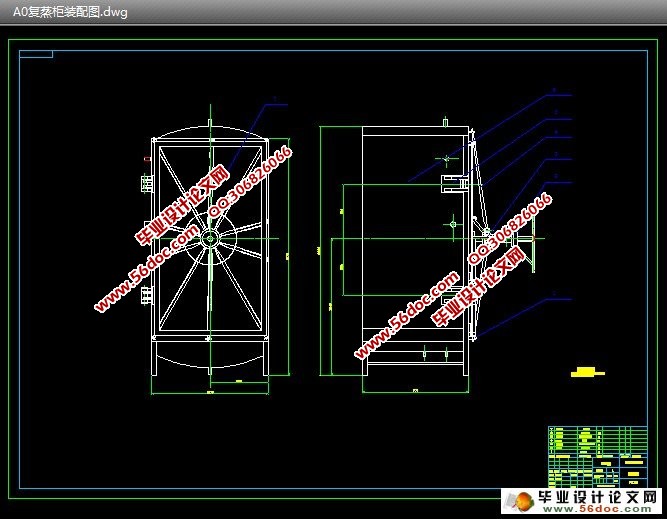

米粉复蒸柜的零部件设计(含CAD零件图和装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

米粉复蒸柜的零部件设计(含CAD零件图和装配图)(论文说明书13800字,CAD图36张,答辩PPT)

摘要

米粉,也叫米线,米粉是指以大米为原料,经浸泡、蒸煮、压条等工序制成的条状、丝状米制品,而不是词义上理解的以大米为原料以研磨制成的粉状物料。它们的生产工艺大同小异,一般为:大米 — 淘洗 — 浸泡 — 磨浆 — 蒸粉 — 压片(挤丝)—复蒸 — 冷却 — 干燥 — 包装 — 成品。复蒸柜是利用高温蒸米粉,提高米粉的α度,降低米粉的吐浆率,且使米粉有油润感。提高米粉的α度就是高温蒸米粉使米粉的胶束结构完全崩溃散开,也就是使淀粉糊化。α米粉的味道好,且易于消化,这是因为α-淀粉被水所包围,胶束完全崩溃散开,在直链淀粉和支链淀粉各个分子之间形成间隙,消化酶容易发生作用。 理论上。在100℃时加热10—30分钟,使其糊化,但实际上要蒸30分钟以上才行,有的工厂需蒸一小时。在108℃压力为0.4kg/cm²下加热米粉更易糊化,吐浆率低且有油润感。因此对复蒸柜的保温和密封有较高的要求,即对柜门的密封结构和压紧结构均有较高的要求。

关键词 复蒸柜 密封 压紧结构

The rice noodle duplicate steams the cabinet the spare part design

Abstract: Rice noodle, is also called the rice-flour noodle, the rice noodle is refers to take the rice as raw material, after the immersion, the steam boiling, holds down strip and so on working procedures to make strip, the filiform rice product, but is not in the word meaning understands by the rice the powdery material which grinds for raw material makes. Their technique of production is mostly the same except for minor differences, generally is: The rice - elutriate - immersion - grinding paste - steams the powder - sheeting (to push silk) - duplicate to steam - the cooling - dry - packing - end product. Steaming a chest again is to make use of the high temperature steaming ground rice , improve the ground rice alpha degree, reducing ground rice's spits out thick fluid rates, and lets ground rice have smooth feeling of oil. That the alpha raising ground rice it is the high temperature to steam ground rice degree makes the ground rice micel structure collapse completely dispersing , the messenger amylum paste melts that is . Alpha ground rice flavour is easy to digest at present easily, this is that complete breakdown of micel disperses because of alpha-amylum is surrounded by water, effect happened easy to form the gap , the digestive enzyme between straight chain amylum and each molecules of branched chain amylum.Theoretically. But o'clock heats 10 to 30 minutes , messenger it's paste melts in 100℃, only row , some factories need steaming an hour above needing to steam 30 minutes in fact. The easier to heat ground rice in 108 ℃pressure for 0.4kg/cm²paste is molten , is spits out thick fluid rates low and is has smooth feeling of oil. Have higher call for therefore to heat preservation and hermetic sealing steaming a chest again , be that the structure sealing off structure and compacting has higher call for equally to the chest.

Key words: Duplicate steams the cabinet Seal Compaction structure

复蒸柜是利用高温加热米粉,提高米粉α度。降低米粉吐浆率且使米粉,有滑油润感。

本复蒸柜具有以下特点:

(1) 一次性能够对120kg米粉进行加工;

(2) 加工时间比传统的糊化工艺大大缩短;

(3) 能够充分的让糊化;

(4) 设备安生可靠,管理方便,操作简单,制造容易和投资少;

(5) 机械设备易于调节,易于拆洗。

目 录

摘要 1

一.绪论 4

1.1前言 4

1.2复蒸柜原理 5

1.2.1、淀粉的糊化 5

1.2.2、淀粉的回生 7

1.2.3、米粉糊化与回生在复蒸柜生产中的指导作用 8

二.柜门机构 9

2.1 内框 9

2.2 衬板 10

2.3 门板 10

2.4 下平板 10

2.6.柜门的密封结构 11

2.7.柜门总成 12

三.压紧机构 13

3.1 压紧机构的选择 13

3.2 作用点的确定 13

3.3 压紧机构结构的确定 15

3.3.1 楔杆 15

3.3.2 压紧支承座 18

3.3.2轴 18

3.3.3 前、后夹板 20

3.3.4套筒 22

四. 手轮 23

五.门支承座 24

参 考 文 献 27

致谢 28