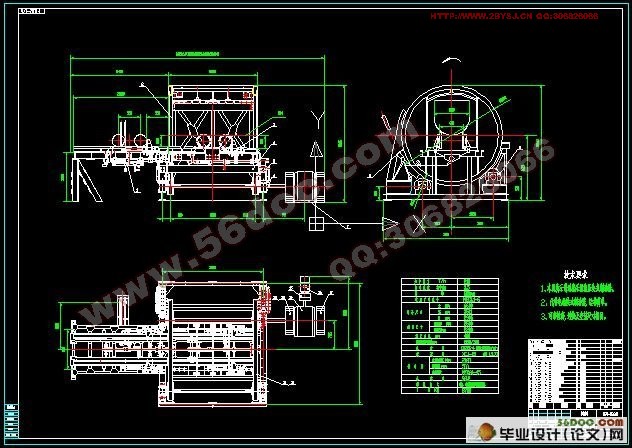

一吨不摘钩翻车机的设计

无需注册登录,支付后按照提示操作即可获取该资料.

一吨不摘钩翻车机的设计(含开题报告,毕业论文18000字,实习报告,外文翻译,CAD图纸4张)

摘 要

翻车机最早应用于矿山当时称矿山翻笼其依靠钢丝绳驱动完成翻卸作业。在此基础上经不断演变最终成为当前翻卸车辆的专用机械。

实现翻车机能连续自动工作,所以这次设计的主要方向是对焦煤集团赵固一矿用的翻车机的改造设计,其传动系统和控制系统的改造,使其能够实现自动化翻车。这次的改造使其比以往的老式翻车机更具有人性化的特点,使人的工作量大大的减小,操作更加简单。 老式的翻车机大多是齿轮传动,继电器控制。这种体系结构机械冲击大,电气事故率高,很难维护,为了解决这一难题,我决定采用液压传动作为动力源,可编程控制器(PLC)为核心的电气控制系统。

液压传动有以下优点:

1、与机械传动和电气传动相比,在相同功率情况下,液压传动系统的体积小、重量较轻、故障率低,可靠耐用。

2、工作平稳,换向冲击小,便于实现频繁转向。便于实现过载保护,而且工作油液能使传动零件实现自润滑,因此使用寿命长。

3、操纵简单,便于实现自动化,特别是与电气控制联合使用时,易于实现复杂的自动工作循环。

4、机器结构简化,布置灵活、翻车、停车非常平稳,不烧电机,不存在摔车的现象。

5、液压元件实现了系列化、标准化和通用化,易于设计、制造和推广应用。

所以我提出了以下设计改造方案:

首先对翻车机的动力系统进行改造设计。用液压系统来替代翻车机老式的电动机减速器传动方式。用液压泵来驱动翻车机液压马达,。其次对翻车机的控制系统进行改造。用 PLC 可编程控制器来代替翻车机老式的继电器控制。

关键词:翻车机 翻卸作业 可编程控制器(PLC) 液压传动 过载保护 继电器控制

ABSTRACT

The earliest application in mining was dumper said the wire rope over mine cage on driving over homework finished unloading. Based on this the ever-evolving eventually become the un-loading the special machine over vehicles. To realize the continuous automatic work dumper, so this time the design of the main direction of coking coal Zhao Gu group is a mine of reform of the counter design, and its drive system and control system transformation, so it can realize the automation overturned.

The reconstruction of the old car dumper than ever more with the human characteristics, make the person's workload greatly reduces, operation easier. The old car dumper is mostly gear transmission, relay control. The system structure of the great mechanical shock, electric rate high, and difficult to maintain, in order to solve the problem, I decided to adopt hydraulic transmission as a power source, programmable controller (PLC) is the core of the electrical control system.

Hydraulic transmission has the following advantages:

1. and mechanical drive and electrical transmission compared, in the same power, hydraulic transmission system of small volume, light in weight, low failure rate, reliable and durable.

2. smooth, impulsion is small, easy to realize frequent turning. Easy to achieve overload protection, and the work the oil can make the trans- mission parts realize self lubrication, so long service life.

3. and manipulation of simple, easy to realize automatic, especially when combined with the electrical control, easy to realize complex automatic work cycle.

4. machine structure is simplified, decorate flexible, overturned, parking very smoothly, doesn't burn motor, there is no car broke the phenomenon.

5. hydraulic components realized the seriating, standardize-tion and universal, easy to design, manufacture and application.

So I put forward the following design reform plan:

First the dumper power system design modification. With the hydraulic dumper system to replace the old motor reduce drive way. Use to drive the car dumper hydraulic pump hydrauliccmotor. Secondly the dumpers control system to reform. Use PLC programmable controller to replace dumper old-fashioned relay control.

Key words: dumper turns over the discharge operation programmable controller (PLC) hydraulic transmission overload protection relay control

目 录

前 言 1

1 选题的目的和意义 4

2 毕业设计计算说明书 5

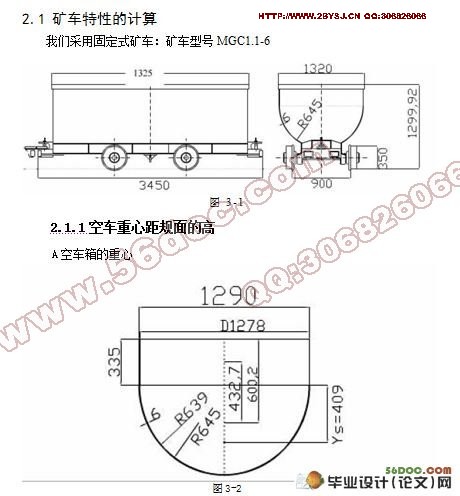

2.1 矿车特性的计算 5

2.1.1空车重心距规面的高 5

2.2 翻车机的计算 8

2.2.1 摩擦阻力矩的计算 8

2.2.2静不平衡力矩计算 14

2.2.3 总阻力矩计算 16

2.2.4 驱动翻笼的最大功率 17

2.2.5 传动轮对滚筒的滑转验算 17

2.2.6 滚轮与滚筒接触强度的验算 18

2.2.7缓冲弹簧的计算 19

3 液压系统的设计 33

3.1 设备概况 33

3.2 翻车机液压系统的设计要求 34

3.2.1 拟制液压系统图如下 35

3.2.2 液压系统的计算 35

3.2.3 液压元件的选择和计算 36

3.2.4 液压元件的选择验算 36

3.3液压系统发热量的计算 39

3.4 系统的散热量 42

4 电控系统设计 44

4.1 推车机、翻车机电控设计要求 44

4.1.1推车机电控系统能够完成的功能 44

4.2推车机和翻车机的工作方式 44

4.2.1 起始状态 44

4.2.2 联动方式 44

4.2.3手动工况 45

4.2.4 煤仓煤位保护 46

4.2.5故障显示及闭锁 46

4.3可编程控制器的选择 46

4.4 自动推车机翻车机程序的绘制 47

5翻车机传动负载计算 51

5.1散料对回转中心力矩计算分为三部分 51

5.2 翻车机偏载平衡方法和对回转中心的最大静载力矩 57

5.3 翻车机加速转矩和电机选择 59

结 论 60

致 谢 61

参考文献 62

附 录 64