实用卧式钢筋切断机的设计

无需注册登录,支付后按照提示操作即可获取该资料.

实用卧式钢筋切断机的设计(cad图纸11张,论文说明书7600字)

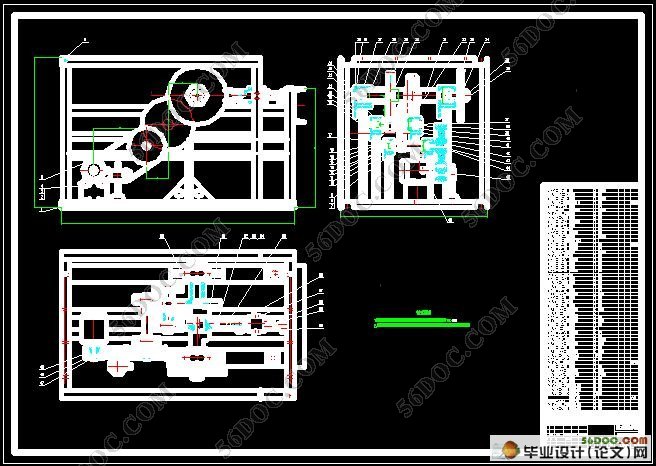

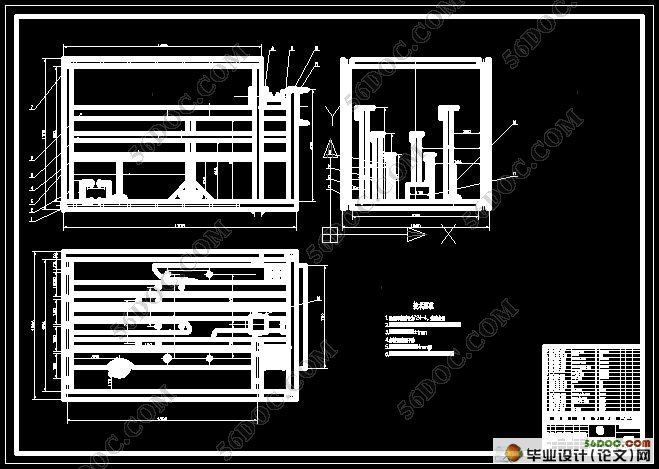

摘 要:根据现有切断机的类型和特点,我设计了一种结构比较简明实用的钢筋切断装置。该切断机是采用电动机经一级带传动和二级齿轮传动减速后,带动曲轴旋转, 曲轴推动连杆使滑块和动刀片在机座的滑道中作往复直线运动,使活动刀片和固定刀片相错而切断钢筋。动力由电动机输出,通过减速系统传动,把动力输入到执行机构。由于传动系统作的是回转运动,而钢筋切断机的执行机构需要的直线往复运动,为了实现这种转换,可以采用曲柄滑块机构,盘行凸轮移动滚子从动件机构, 齿轮齿条机构。本课题采用曲柄滑块机构作为本机械的执行机构。该装置的特点是价格低廉,节省空间,维修方便。

关键词:钢筋;齿轮;曲柄滑块

Devising of The Horizontal Steel Cutting Machin

Abstract :According to existing types and characteristics of cutting machine, I designed a kind of structure cutting device is concise and practical reinforced. The cut-off machine is adopted by level one belt transmission motor and two gear deceleration, drive after crankshaft, crankshaft promote slider and dynamic linkage to the slide in the base of reciprocating linear motion, making activity blades and fixed blade is wrong and cut reinforced. The transmission system for the rotary movement, while the steel cutting machine implementing agencies need a straight line reciprocating motion, in order to achieve this conversion, it can be using slider-crank mechanism, driving line roller cam follower bodies, the gear rack mechanism .This subject adopts slider-crank mechanism as the mechanical actuators. This device is characteristic of low prices, saving a space, easily covenanting。

Key words: reinforced ; gear; slider-crank

目 录

摘要……………………………………………………………………………………1

关键词………………………………………………………………………………1

1前言…………………………………………………………………………………2

1.1钢筋切断机的工作原理……………………………………………………2

1.2课题设计的目的和内容……………………………………………………2

2卧式钢筋切断机的总体结构…………………………………………………2

2.1现有钢筋切断机的类型、特点 ………………………………………2

2.2总体方案的拟定…………………………………………………………3

3电机的选择…………………………………………………………………………3

3.1 钢筋切断机需用力计算…………………………………………………3

3.2 功率计算…………………………………………………………………4

4 传动结构设计……………………………………………………………………4

4.1 基本传动设计计算………………………………………………………4

4.2 带传动设计………………………………………………………………5

4.3 齿轮传动设计…………………………………………………………7

4.4 轴的校核………………………………………………………………13

4.5 键的校核………………………………………………………………19

4.6 轴承的校核……………………………………………………………20

5 卧式钢筋切断机的总体结构设计………………………………………………23

6 钢筋切断机的摩擦分析和润滑…………………………………………………23

7 结论………………………………………………………………………………23

参考文献 ………………………………………………………………………24

致谢……………………………………………………………………………25