加工石英表铁芯的级进模具设计

无需注册登录,支付后按照提示操作即可获取该资料.

加工石英表铁芯的级进模具设计(含任务书,开题报告,中期检查报告,毕业论文说明书10000字,cad图纸9张零件图1张装配图)

摘 要

本设计的题目是加工石英表铁芯的级进模具,通过对方案的选择排样的计算,冲压力的计算和压力中心确定的计算以及凸凹模刃口的计算等使本副模具基本符合冲压要求,由于石英表铁芯的面积较小,材料较薄并且Cr12硬度很高,中间横梁的连接处宽度只有0.8mm,所以加工难度大设计困难。0.8mm的凸模不容易加工出来,所以采取级进模具加工(本副模具为2个工位)先冲孔,再用组合凸模经过两次送进完整的落料实现零件的成形,只有这样才避免冲孔后直接落料 0.8mm宽的横梁的麻烦。

级进模具的精度要求很高导向要求十分精确,在设计本副模具时遇到很大的阻力经过对各方案的选择和排除最终才选择此方案。通过近三周的拼搏,本副级进模具设计终于完成。根据标准模架的选择,制作凸凹模材料的选择以及导向和送进精度的确定本模具所加工出的石英表铁芯满足要求,符合市场的需要。

由于设计者的能力所限,设计中的不足之处还有好多例如:材料利用率方面仅21%,会对经济效益有影响,但材料利用率的大小由工件形状和排样决定,石英表铁芯两边大且不对称,中间很窄所以排样后材料利用率较低。还有多工位级进模具益采用四角导柱模架—《实用模具技术手册》,本模具的冲裁力不大精度基本能保证的前提下选择了中间导柱模架。相信不久本模具投入市场一定能带来很好的效益服务大众,服务社会。

关键词:模具设计与制造,CAD软件,工艺分析。

Mold design of the processing quartz form iron core

Summary

Topic that design originally to process quartz form grade , iron of core enter mould , rank the calculation of kind through the choice to the scheme, it makes this pair of moulds accord with the request of pressing basically to press calculation , calculation which the pressure centre confirm and calculation of the protruding concave mould blade of strength ,etc., because the area of the quartz form iron core is relatively small, the material is very more high in hardness than thin and Cr12, there is only 0.8mm in the width of junction of the middle crossbeam , so process the degree of difficulty and design the difficulty greatly. The protruding mould of 0.8mm is not easy to process out, so adopt grade enter the mould and process (this pair of moulds are for 3 pieces of engineering location ) and wash holes first , and then send to intact blanking and realize the taking shape of the part twice by making the protruding mould up, only in this way avoid washing the trouble of the direct blanking 0.8mm wide crossbeam after holes.

Grade enter precision of mould expect very much and lead demanding to be very accurate, the obstruction that it is very great to meet while designing this pair of moulds is through and gets rid of and chooses this scheme to the choice of every scheme finally. Through the striving of nearly three weeks, this each enters mold design to finish at last. According to the choice of the standard mould shelf, choice , direction and quartz form iron core processed of a mould of sureness sent to the precision of making protruding concave mould material meet the demands, meet market's needs.

The because designer one it restrict with ability, have much weak point in design for example: The material utilization ratio is only 21%, will influence economic benefits, but the size of the material utilization ratio and arranges one kind of decisions by the form of the work piece, the quartz form iron core both sides are large and asymmetric, the material utilization ratio is relatively low after the middle is very narrow to arranges kind. There is many workers location grade that enters benefit of the mould and adopts four mao and leads the post mould shelf - " practical mould technical manual ", the blanking strength of this mould leads the post mould shelf the middle not quite choosing under the prerequisite that the precision can be guaranteed basically. Can unquestionably bring very good benefit and serve the general public to invest the market while believing a mould soon, serve the society.

Keyword:Mold design and making,CAD software,craft analysis.

插图清单

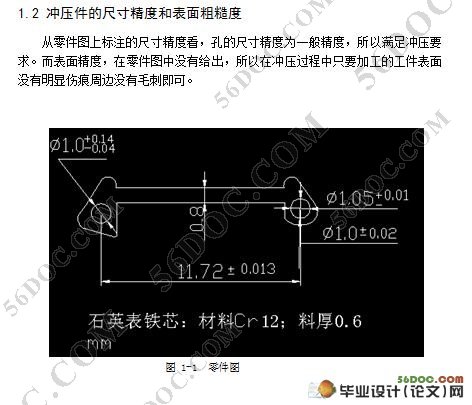

1. 图 1-1:工件图--------------------------------------------------------------------3

2. 图 3-1:排样图--------------------------------------------------------------------5

3. 图 3-2:坐标系下凹模形口----------------------------------------------------------9

4. 图 4-1:组合式凸模---------------------------------------------------------------12

5. 图 4-2:冲孔凸模-----------------------------------------------------------------13

6. 图 4-3:固定挡料销---------------------------------------------------------------14

7. 图 4-4:卸料板-------------------------------------------------------------------15

8. 图 6-1:模架简图-----------------------------------------------------------------18

9. 图 6-2:模柄---------------------------------------------------------------------19

表格清单

表 3-1:材料利用率的计算表 ----------------------------------------------------- 6

表 3-2:冲压力的计算表 --------------------------------------------------------- 7

表 3-3:压力中心计算数值表 ----------------------------------------------------- 9

表 3-4:凸凹模刃口尺寸计算表 --------------------------------------------------- 10

表 6-1:模柄标准尺寸表 --------------------------------------------------------- 18

表 7-1:压力机型号表 ----------------------------------------------------------- 20

表 8-1:模具装配表 ------------------------------------------------------------- 21

表 9-1:机械加工工艺过程卡 ----------------------------------------------------- 22

表 9-2:模具典型零件机械加工工序卡 --------------------------------------------- 24

#p#副标题#e#

毕业设计/论文说明书目录

绪 论 ---------------------------------------------- 1

第一章 零件的工艺性分析 -------------------------- 3

1.1 工件的结构工艺性分析 -------------------------- 3

1.2 工件的尺寸精度和表面粗糙度的确定 -------------- 3

第二章 冲压方案的拟订 ------------------------------ 4

2.1 加工方案的确定 -------------------------------- 4

2.2 零件材料的分析 -------------------------------- 4

第三章 设计的主要计算 ----------------------------- 5

3.1排样 ------------------------------------------- 5

3.2冲压力的计算 ----------------------------------- 7

3.3确定压力中心 ----------------------------------- 8

3.4凸,凹模刃口尺寸计算 -------------------------- 10

3.5卸料装置的设计 -------------------------------- 11

第四章 主要零部件设计-----------------------------12

4.1 工作零件的结构设计 -------------------------- 12

4.1.1 落料凸模设计 ---------------------------- 12

4.1.2 孔凸模设计 ------------------------------ 12

4.1.3 凹模设计 -------------------------------- 13

4.2 定位零件的设计 ------------------------------ 13

4.3 导料销的设计 -------------------------------- 14

4.4 卸料部件的设计 ------------------------------ 14

4.4.1 卸料板的设计 ----------------------------- 14

4.4.2卸料螺钉选用 ------------------------------ 15

第五章 模具总体设计 ----------------------------- 16

5.1 模具类型的选择 ------------------------------ 16

5.2 定位方式的选择 ------------------------------ 16

5.3 卸料,出件方式的选择 ------------------------ 16

5.4 导向方式的选择 ------------------------------ 16

第六章 模架及其它零部件设计 -----------------------17

6.1 模架的设计 -----------------------------------17

6.2 圆柱销设计 ---------------------------------- 18

6.3 模柄的设计 ---------------------------------- 18

6.4 模具总装图 ---------------------------------- 19

第七章 冲压设备的选定 ----------------------------- 20

第八章 模具的装配 -------------------------------- 21

第九章 模具典型零件机械加工工序卡 -------------- 22

设计总结 ------------------------------------------- 25

致谢-------------------------------------------- 26

参考文献----------------------------------------- 27

参考文献

1. 许发樾主编. 实用模具设计与制造. 机械工业出版社,2002.

2. 中国机械工程学会、中国模具设计大典编委会. 中国模具设计大典. 江西科学技术出版社,1998.

3. 模具设计与制造技术教育丛书编委会编.模具制造工艺与设备.机械工业出版社,1996.

4. 林慧国、火树鹏、马绍弥主编. 模具材料应用手册. 机械工业出版社,2004.

5. 冯炳尧、韩泰荣、蒋文森编,丁战生审. 模具设计与制造简明手册(第二版).上海科学技术出版社,2003.

6. 模具制造手册编写组编写. 模具制造手册(第二版). 机械工业出版社,2002.

7. 郝滨海编. 冲压模具简明设计手册. 化学工业出版社,2000.

8. 杨占尧编. 冲压模具图册. 高等教育出版社,2002.

9. 刘建超、张宝忠编. 冲压模具设计与制造. 高等教育出版社,2002.

10. 陈锡栋、周小玉主编. 实用模具技术手册. 机械工业出版社,1998.

11. E.Paul De Garmo, JT. Black and Ronald.A.Kohser.Materials and Processes in

Manufacturing.1997