12T焊接滚轮架的机械设计

无需注册登录,支付后按照提示操作即可获取该资料.

12T焊接滚轮架的机械设计(含任务书,开题报告,论文说明书21000字,外文翻译,cad图纸)

摘要: 焊接装备就是在焊接生产中与焊接工序相配合,有利于实现焊接生产机械化、自动化,有利于提高装配焊接质量,促使焊接生产过程加速进行的各种辅助装置和设备。焊接工装在焊接机械化中也扮演着重要的角色,采用工装夹具,工件定位迅速,装夹方便,省力,减轻了焊件装配定位和夹紧时的繁重体力劳动;焊件的翻转可以实现机械化,变位迅速,使焊接条件较差的空间位置焊缝变为焊接条件较好的平焊位置焊缝,劳动条件改善,同时也有利于提高焊缝的质量。在装配定位焊件时,如果不使用工装夹具,即使焊接组合件由两三个零件组成的,欲保证各零件精确的相对位置也是很难的。同时,在焊接过程中,焊接件一般会由于受热不均等原因而发生焊接变形,尤其是复杂的焊接结构,其变形有时会无法消除,这样就会影响以后的装配工作。采用工装夹具,不仅可以保证焊接时工件间的相对正确位置,而且可以防止和减少工件的焊接变形。批量生产的时候,这种优点就更加明显,可以稳定焊接件的质量,减少次品的产生。焊接滚轮架是借助主动滚轮与焊件之间的摩接力带动焊接旋转的变位机械。焊接滚轮架主要用于筒形焊件的装配与焊接。焊接滚轮架按结构形式分为两类:第一类是长轴式滚轮架。第二类是组合式滚轮架。本文主要对组合式12T焊接滚轮架进行设计,并对轴、键等主要构件进行了校核。结果表明各主要部件符合要求。该滚轮架结构简单,使用方便灵活,对焊件的适应性很强。设计中充分的考虑了滚轮架的合理性和经济性等因素。

关键字:焊接 工装夹具 滚轮架

12 welding roller frame mechanical design

Abstract : Welding equipment is a machine which is used in welding production and welding processes, and it is conducive to welding production mechanization and automation, to improving assembly welding-quality. Then it could prompte to speed up the process of welding production of the various assistive devices and equipment. Welding fixtures also play an important role in Mechanized welding, with fixture, positioning quickly, easy clamping, effort, reduce the weldment assembly positioning and the clamping the heavy manual labor; flip the weldments can be mechanized, rapid deflection, and make the spatial location weld of poor conditions into a better position weld , improved working conditions, at the same time it help to improve the quality of the weld. When in the assembly weldments of positioning, if you do not use the fixture, even if the welding assembly formed by the two or three parts, to ensure the accuracy of the relative position of each part is very difficult. At the same time, in the welding process, the Welding parts generally would occurred welding deformation as uneven heating and other reasons, especially with the welded structures was complex, sometimes its deformation can not be eliminated, this will affect the future work of assembly. With fixture, not only can ensure the correct relative position in welding between the workpiece, but also can prevent and reduce the welding deformation of the workpiece. When in the mass production, this advantage become more apparent, can stabilize the quality of welded parts, reduce the production of defective. Welding roller standing by structural form is divided into two categories : the first category is long axis-wheel frame. the second category is modular roller frame. In this paper, twelve pairs of modular T-welded wheel for the design, as well as axial, bond and other main component of checking. The results showed that the main components to meet the requirements. The roller frame structure is simple, flexible, adaptive welded pieces of a strong, which is the most widely used form of the structure. And it could be fully considered the roller frame reasonable and economic, and other factors.

Keyword: weld frock clamp turning rolls

毕业设计(论文)使用的原始资料(数据)及设计技术要求:

要求设计焊接加工过程中所使用的滚轮机架:

1.根据所给承载量12T建立三维机构模型;

2.选用合理的滚轮架机械方案 ;

3.设计机械零件并校核;

4.绘制滚轮机架装配图一张和零件图若干张;

5.编写设计说明说毕业论文一份;

滚轮架主要用于筒形焊件的装配与焊接。若对主、从动滚轮的高度作适当调整,也可进行锥体、分段不等径回转体的装配与焊接。对于一些非圆长形焊件,若将其装卡在特制的环形卡箍内,也可在焊接滚轮架上进行装焊作业。焊接滚轮架还可配合手工焊或作为检测、装配圆筒体工件的设备。焊接滚轮架的使用能大大提高焊缝质量,减轻劳动强度,提高工作效率。

#p#副标题#e#

目 录

1 引言 1

2 焊接机械设备 2

2.1 焊接机械装备 2

2.1.1焊接机械设备的分类 2

2.1.2焊接机械装备对焊接产生的作用 3

2.2 焊接自动化 3

2.3 焊接工装夹具 4

2.3.1焊接工装夹具的特点 5

2.3.2焊接工装夹具的分类 6

2.3.3对焊接工装夹具的设计要求 6

2.3.4焊件在焊接工装夹具中的定位方法 7

2.4 焊机变位机械 8

2.4.1焊接变位机械的分类 8

2.4.2焊接变位机械应具备的性能 9

2.5 几种焊接设备的具体介绍 9

2.5.1焊接变位机 9

2.5.2焊接翻转机 11

2.5.3焊接操作机 12

2.5.4焊接滚轮架 13

2.5.5关于滚轮架轴向窜动的问题 15

3 方案的选择与确定 17

3.1组合式滚轮架的特点 17

3.2滚轮驱动方案 18

3.3减速器的选择 19

3.4联轴器的选用 20

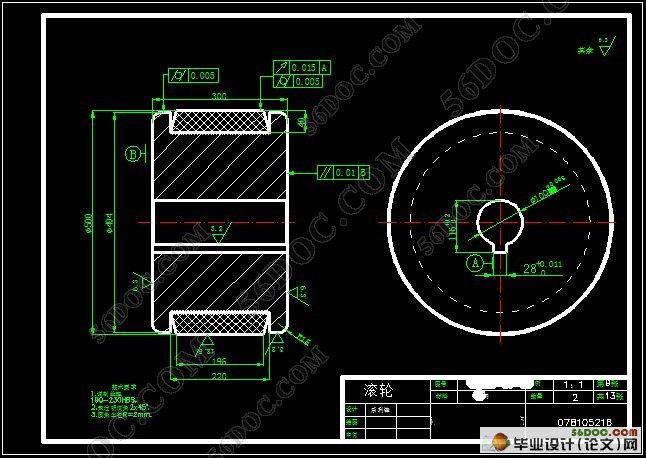

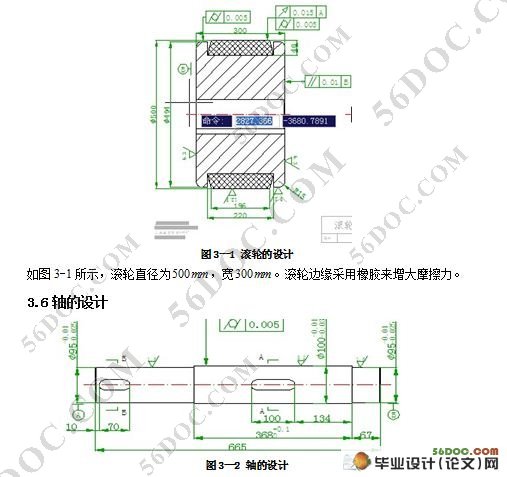

3.5滚轮架滚轮的设计 21

3.6轴的设计 22

3.7轴承的选用 23

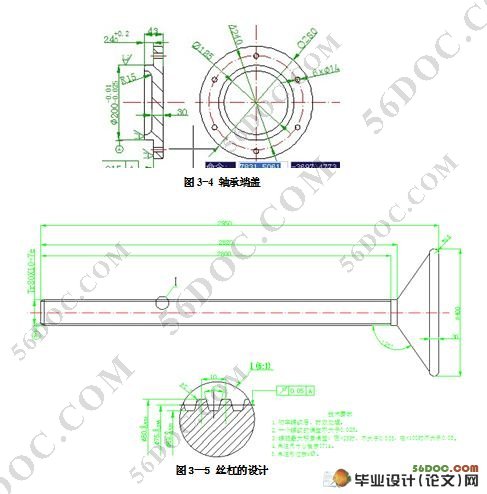

3.8轴承端盖的设计 24

3.9丝杠的设计 25

3.10键的设计 26

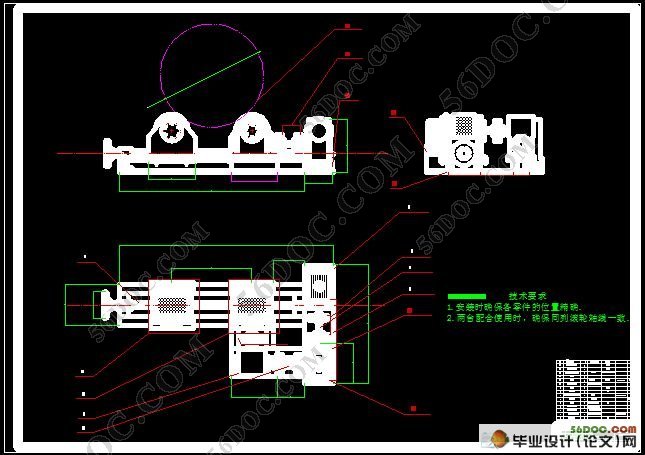

3.11机架的设计 26

3.12表面粗糙度 27

4 计算与校核 28

4.1 焊接滚轮架的设计计算 28

4.1.1驱动圆周力与支反力的分析及中心角的确定 28

4.1.2焊接滚轮架的受力 31

4.1.3滚轮架支反力的计算 32

4.2 电动机的选定 35

4.3 轴的校核 35

4.4 滚轮处键的校核 37

4.5 轴承寿命计算 37

4.6 轴承的强度计算 38

结 论 40

致 谢 41

参考文献 42

附录A 43