中叶板零件冲压工艺与冲模设计(附冲压工艺过程卡)

无需注册登录,支付后按照提示操作即可获取该资料.

中叶板零件冲压工艺与冲模设计(附冲压工艺过程卡)(含任务书,开题报告,论文说明书11000字,外文翻译,13张cad合图)

摘要:模具是工业产品生产用的重要工艺设备,模具工业已是工业发展的基础,许多新产品的开发和研制在很大程度上都依赖与模具的生产。可以预言,随着工业生产的不断发展,模具工业在国民经济中的地位将日益提高,并在国民经济发展过程中发挥越来越重要的作用。在冲压零件的生产中,合理的冲压成形工艺、先进的模具、高效的冲压设备是必不可少的三要素 。

本文介绍了止动件冲压模具的设计,先介绍了对工件进行工艺分析和模具设计的要点,然后介绍了模具设计的思路,模具的主要结构和主要零件的设计。最后确定了选用冲孔落料复合模。

本次设计绘图采用AotuCAD,以AotuCAD为计算机辅助制图工具,使用简单,方便快捷,而且有极强的图形处理功能,可以大大缩短绘图的周期,在国内使用的较广泛。

关键词:冲压模具 落料 冲裁预弯 剪裁 卷圆

stamping process and die design of hinge Vol yen

ABSTRACT :The mold was the important process unit which the manufactured products production used, the mold industry already is the industrial development foundation, many new product's developments and the development relied on to a great extent with mold's production. May predict that along with industrial production's unceasing development, the mold industry will enhance day by day in national economy's status, and plays more and more vital role in the national economy developing process. In the ramming components' production, the reasonable ramming forming craft, the advanced mold, the highly effective ramming equipment are the essential three essential factors. Ramming processing characteristic: Because the cold stamping processing has the above prominent merit, therefore obtained the widespread application in the volume production, holds the very important status in the modern industry production, is the defense industry and in the consumer industry production the essential processing method. this article introduced the lock ramming mold's design, introduced first carries on the process study and the mold design main point to the work piece, then introduced the mold design mentality, mold's primary structure and the major parts design. Finally had determined selects the punch holes to fall the material superposable die. the this design cartography uses AotuCAD, take AotuCAD as the computer auxiliary charting tool, the use is simple, facilitates quickly, and has the greatly strengthened graphic processing function, may reduce cartography greatly the cycle, in domestic use widespread.

key word: Stamping die falls the material Blanking of Preflex Clipping

Vol yen

毕 业设计(论文)使用的原始资料(数据)及设计技术要求:

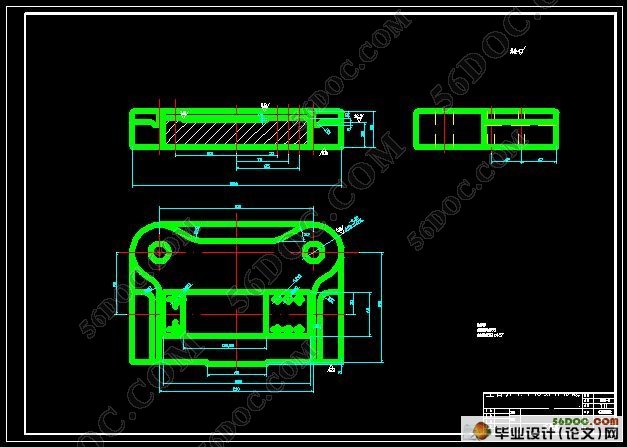

1.中叶板零件图

2.生产纲领:中等批量

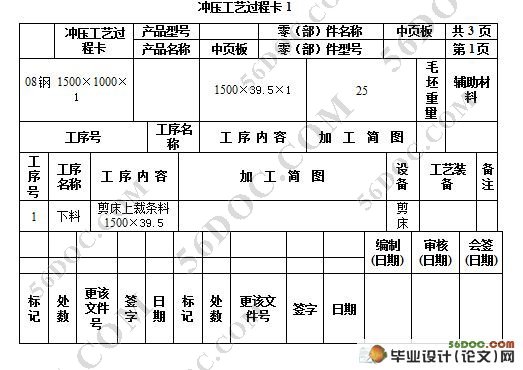

3.要求完成零件的冲压工艺分析和冲压工艺规程的编制。

1) 分析冲件成形工艺、计算坯料展开

2)编制中叶板零件冲压工艺

3)完成中叶板卷圆成形模设计

#p#副标题#e#

目 录

1 引 言 2

1.1概 述 2

1.2模具的发展趋势分: 4

1.3我国冲压技术现状 5

2中页板冲零件冲压工艺于模具设计 8

2.1中页板零件冲压工艺分析 8

2.1.1零件分析 8

2.1.2材料分析 8

2.2确定工艺方案 9

2.2.1冲压工艺的初步选择 9

2.2.3压力机的初步选定 11

2.3冲压模具设计 16

2.3.1模具结构形式的确定 16

2.3.2冲裁模具的简单介绍 16

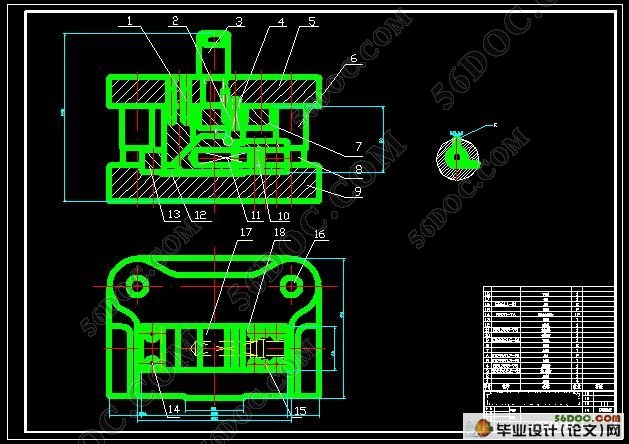

2.3.2卷圆模具的具体设计 17

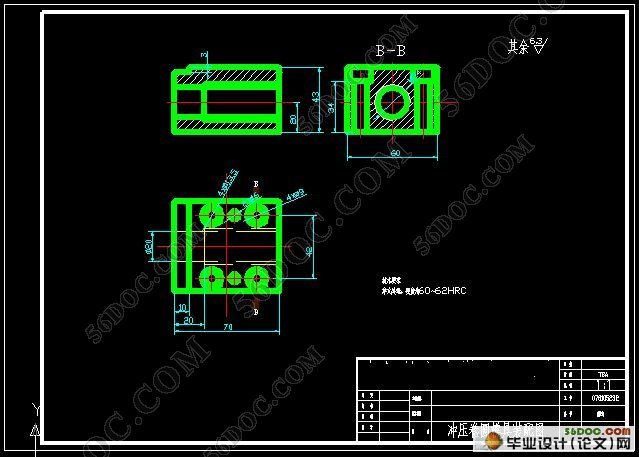

2.3.3模具零件设计及材料的选用 18

(1)滑块的设计 18

(2)斜锲 19

(3)下模块 20

(4)上模快 21

(5)压料块 22

(6)模座 23

(7)模柄的选用 24

(8)导柱,导套的选用 26

2.3.4模具的基本校核 28

(1)计算模具压力中心,确定压力中心的位置 28

(2)压力机校核 28

3 结 论 29

4 参考文献 30

5 致 谢 31