加强板零件的数控加工及夹具设计

无需注册登录,支付后按照提示操作即可获取该资料.

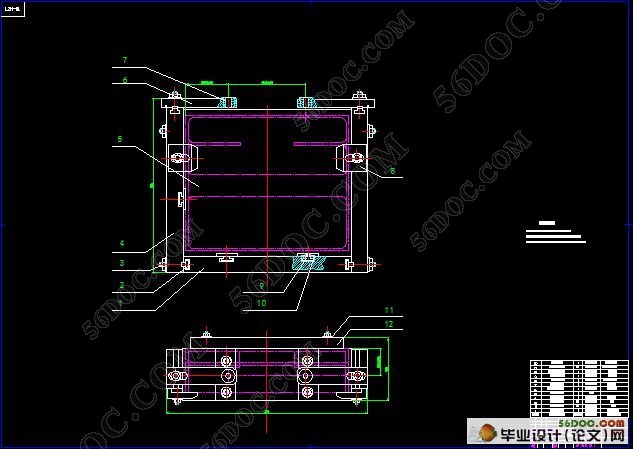

加强板零件的数控加工及夹具设计(含任务书,开题报告,论文说明书10000字,外文翻译,cad图纸,工序卡)

摘要: M5-5加强板零件是某航空产品中的一个薄壁零件,主要起支撑作用因而需要一定的强度和刚度,它是采用LC9铝合金材料,能满足其性能要求。航空产品一般是单件小批量生产,故适宜采用数控加工生产。本毕业设计课题的设计内容主要包括M5-5加强板零件数控加工和钻孔用组合夹具拼装两个部分。数控加工部分主要有零件的实体模型的建立、数控加工工艺规程编制、刀具、切削用量及主轴转速的选择,以及零件的仿真数控加工,并利用UG软件自动生成相应工序的数控加工程序。实体模型的建立是利用UG现有的块、圆柱体、圆锥体和球体四种简单的实体模型,通过建模合理性和参数化要求出发,根据M5-5加强板零件的特点创建符合数控加工的实体模型。根据粗、精加工分开的原则合理编制数控加工工艺规程。根据工件材料及所用机床选择适合的刀具及切削用量。组合夹具拼装部分主要有组合夹具的总体设计、相关组合夹具元件的选择,定位基准的选择及夹紧方法的选择以及加工误差精度分析。

关键字:实体建模 数控加工 工艺规程 组合夹具

The numerical control processing and jig of Strengthen the plank part are designed

Abstract : M5-5 Strengthen the plank part some aviation products one of frame thin wall part, it need certain intensity and rigidity to play a supporting role mainly, it adopts the aluminium alloy material of LC9, can meet its performance demand . Aviation products single piece light to produce in batches generally, is it adopt numerical control process production to suit. Aviation products single piece light to produce in batches generally, is it adopt numerical control process production to suit. This graduation project design of subject content mainly including M6-6 little floor part numerical control process and hole with make up jig assemble two parts. Numerical control process part for entity foundation , numerical control processing technology rules make , cutter , cut consumption and choice , main shaft of rotational speed of model of part, and artificial numerical control of part process, utilize UG software turn into corresponding numerical control of process process the procedure automatically. Foundation, entity of model to utilize UG existing piece , round cylinder , cone , spheroid 4 kinds of simple entity models, is it set out to demand through modeling rationality and parameter , is it accord with the entity model processed in numerical control to establish according to M5-5 Strengthen the plank characteristic of part. According to thick, principle that finish machining separate work out the processing technology rules of numerical control rationally. And choose the suitable cutter and cutting consumption with the lathe according to the work piece material. Making the jig up has overall design which makes the jig up , relevant choices of making the jig component up to assemble mainly, orient the basic choice and choice of clamping the method and process the analysis of precision of error.

Keyword: Entity's modeling Numerical control is processed Craft rules Rotational speed of the main shaft

#p#副标题#e#

目录

1. 引言--------------------------------------------------------------1

2.钻孔用组合夹具拼装设计------------------------------------------2

2.1组合夹具的特性--------------------------------------------2

2.2 组合夹具的元件及其作用 -----------------------------2

2.3 加强板零件钻孔组合夹具总体设计-------------------- 6

2.3.1组合夹具的元件选择---------------------------- 6

2.3.2组合夹具的拼装方案设计------------------------7

2.4组合夹具的误差分析及计算--------------------------------8

2.4.1导向误差计算 -------------------------------------8

2.4.2 定位元件的误差分析-------------------------------8

2.4.3钻削力---------------------------------------------9

3.加强板零件的数控加工 -------------------------------------10

3.1 加强板零件实体模型的建立与编辑 --------------------10

3.1.1 加强板零件实体模型的建立与编辑

3.1.1.1实体模型的概念 ----------------------------10

3.1.1.2实体模型术语--------------------------------10

3.1.1.3 实体模型的概念------------------------------11

3.2.1 实体模型基本体素-----------------------------------11

3.2.1.1 圆柱体---------------------------------------11

3.2.1.2长方体----------------------------------------11

3.2.1.3球体------------------------------------------11

3.3.1 扫描特征-------------------------------------------12

3.3.1.1拉伸体---------------------------------------12

3.4.1基准轴---------------------------------------------12

3.5.1布尔操作-------------------------------------------12

3.6.1成型特征-------------------------------------------13

3.6.1.1成型特征用于模型的细节设计-----------------13

3.6.1.2 孔--------------------------------------------14

3.7.1操作特征 -------------------------------------------15

3.7.1.1边倒圆 ---------------------------------------16

3.7.1.2修剪实体--------------------------------------17

3.8.1草图------------------------------------------------17

3.2零件的数控加工工艺基础----------------------------------- 20

3.3数控加工方案的确定-----------------------------------------21

3.4 加强板零件的UG数控加工程序的生成 ------------------21

3.5 加强板零件的数控加工的加工方式及参数确 ------------22

3.5.1切削用量及刀具的选择----------------------------22

3.5.2数控加工坐标选择--------------------------------24

3.6仿真加工软件简介-------------------------------------------24

4.总结----------------------------------------------------------------26

参考文献 -------------------------------------------------------------27

致谢 -----------------------------------------------------------------28

附录

A:译文及外文原始资料

B: CXQ程序单