高铁路基箱梁式整体研磨机的设计

无需注册登录,支付后按照提示操作即可获取该资料.

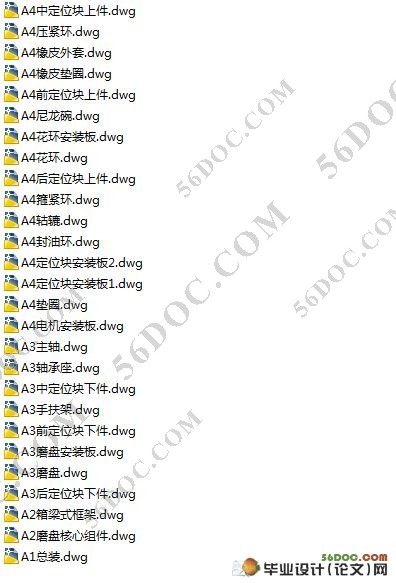

高铁路基箱梁式整体研磨机的设计(选题审批表,任务书,开题报告,中期检查表,论文说明书11500字,cad图纸,成绩评定册)

摘 要:本次设计的高铁箱梁整体研磨机,框架采用箱梁式一体化设计,将九个磨盘整体安装,可将高铁路基一次性整体加工到位。又采用高速交流电机直接驱动磨盘的突破性设计,节省传动结构,减少一些中间环节的不稳定性及其误差。本设计旨在提高高铁路基的修建精度和效率,将对高铁的快速发展,乃至经济的高速发展产生深远的影响。

关键词:箱梁式;高铁路基;研磨机

Design of High-speed Railway Concrete Architrave Overall Grinding Machine

Abstract: This project was a design of integrate grinding machine for high-speed rail road. In this project, the skeleton of the machine was designed in a box-type way. It installed nine grinding chute integrally, which perfectly machined the substructure of the high-speed rail once and for all. Moreover, this project intended to drive the grinding chute by high-speed ac motor directly. With this design, not only the rolling teeth transmission could be cut down, but also errors and instability of the intermediate process could be reduced. This project was aimed at promoting the accuracy and efficiency in the building for substructure of the high-speed rail road. And it would bring profound impacts on the development of high-speed rail road, and even more profound effects on the development of economy.

Key words: box-type girder, substructure of the high-speed rail, grinding machine

#p#副标题#e#

目 录

摘要……………………………………………………………………………………1

关键词…………………………………………………………………………………1

1 前言…………………………………………………………………………………1

2项目整体介绍…………………………………………………………………………2

2.1高铁的意义……………………………………………………………………2

2.2高速铁路的运输优势…………………………………………………………2

2.3高铁路基特点介绍……………………………………………………………2

2.4整体研磨机工作条件与要求…………………………………………………2

3 整体方案设计………………………………………………………………………3

3.1项目应有的工作条件及参数分析……………………………………………3

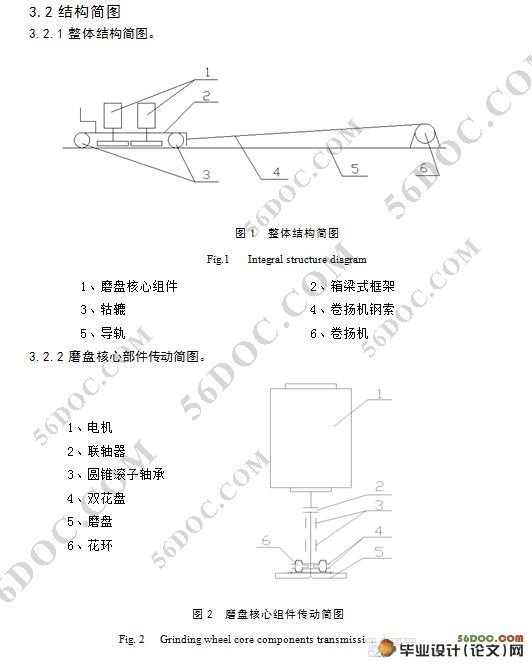

3.2结构简图………………………………………………………………………3

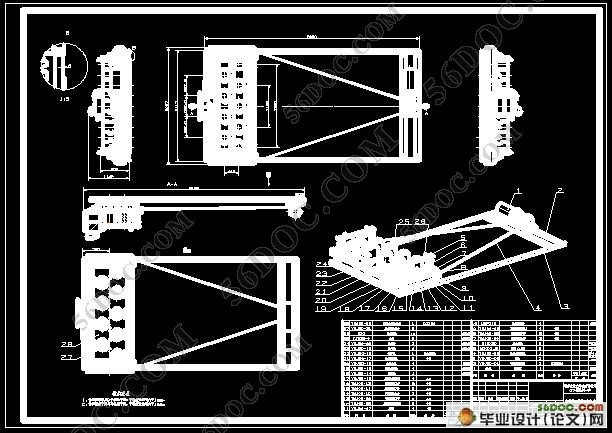

3.2.1整体结构简图…………………………………………………………3

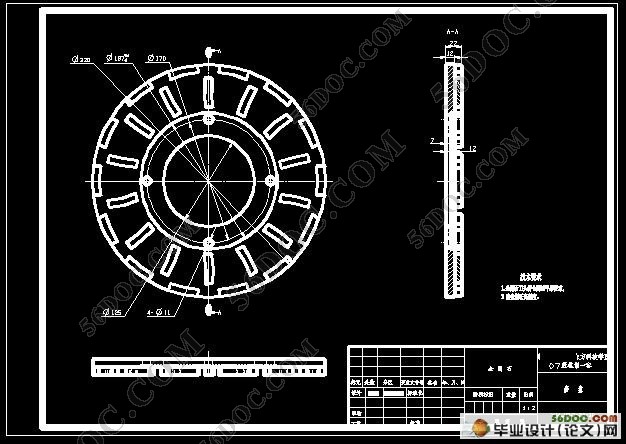

3.2.2磨盘核心部件简图……………………………………………………4

4电机选型………………………………………………………………………………4

4.1电动机类型和结构形式………………………………………………………4

4.2电机容量选择…………………………………………………………………6

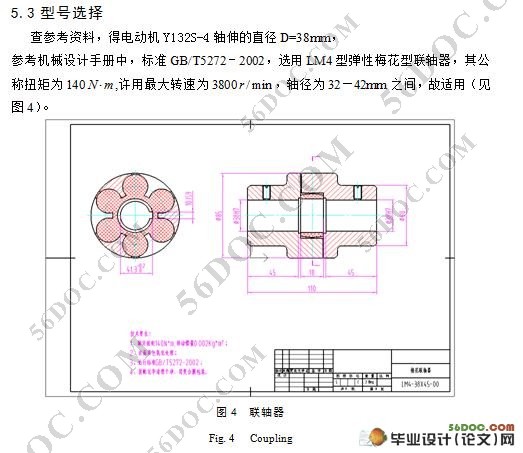

5联轴器的选择…………………………………………………………………………6

5.1类型选择………………………………………………………………………7

5.2公称转矩………………………………………………………………………7

5.3型号选择………………………………………………………………………7

6主轴的设计计算………………………………………………………………………8

6.1初步确定轴的最小直径………………………………………………………8

6.2轴的结构设计…………………………………………………………………8

6.2.1根据轴向定位要求确定轴各段直径和长度…………………………8

6.2.2初选轴承………………………………………………………………9

6.3轴上零件的周向定位…………………………………………………………9

6.4确定轴上圆角和倒角尺寸……………………………………………………9

6.5求轴上载荷…………………………………………………………………10

6.6按弯扭合成力校核轴的强度………………………………………………11

6.7精确校核轴的疲劳强度……………………………………………………12

7磨盘的设计…………………………………………………………………………14

8滚动轴承的选择和强度校核………………………………………………………15

8.1初选轴承……………………………………………………………………15

8.2轴承使用寿命计算…………………………………………………………15

9键连接的选择和校核计算…………………………………………………………16

10结构介绍……………………………………………………………………………16

10.1整体结构介绍………………………………………………………………16

10.2分支机构介绍………………………………………………………………17

10.2.1卷扬机………………………………………………………………17

10.2.2导轨的选择…………………………………………………………17

10.2.3轱辘的选用与安装…………………………………………………19

10.2.4定位器………………………………………………………………20

10.2.5磨盘核心组件介绍…………………………………………………21

10.2.6梁式结构介绍………………………………………………………22

10.2.7液压系统介绍………………………………………………………23

10.2.8设备整体图片展示…………………………………………………23

11总结…………………………………………………………………………………25

参考文献…………………………………………………………………………27

致谢………………………………………………………………………………28