电风扇上盖的注塑模具设计(CAXA)

无需注册登录,支付后按照提示操作即可获取该资料.

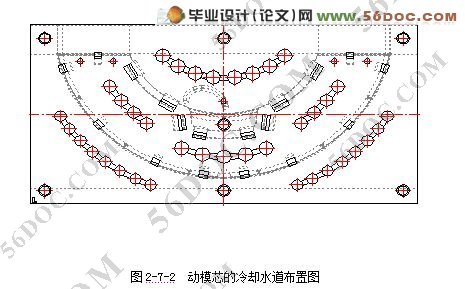

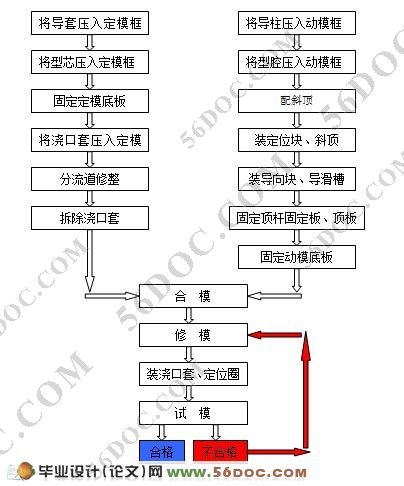

摘要:本文主要介绍了带有18处侧槽或侧钩的电风扇上盖从工艺性分析 模具总体结构设计 注塑机选用 模具装配的一种注塑模具设计过程。其最大的亮点在于塑件上的18处侧槽或侧钩在侧抽芯无法实现的情况下均采用斜顶机构来解决,在未来几年,该技术将被广泛应用于各种带有侧槽或侧钩等的注塑模具中。

关键词:电风扇上盖,侧槽或侧钩,斜顶机构,注塑成型

The washer machine cover of note the plastics molding tool design

Abstract: This text mainly introduces to take the washer machine cover of have 18 side slots or the side hooks to analyze from the craft Total structure design of molding tool Note the plastics machine chooses to use A kind of plastics molding tool design process that molding tool assemble.It is a little bit biggest and bright to lie in 18 side slots or the side hook of the plastics piece to all adopt an organization under the condition that side takes out and can't carry out to solve, at several years of future, that technique will be been apply in various plastics molding tool that takes to have the side slot or the side hook etc. extensively in.

Keyword: The washer machine cover, the side slot or the side hook, an organization, injects the plastics to model.

本次设计选择的是电风扇上盖,电风扇上盖采用当前最常用的工程塑料ABS注塑成型,由于其生产批量为每年20万件,为大批量生产,在保证塑件质量的前提下,希望能采用一模多腔或高速自动化生产来缩短生产周期,而根据实际生产的要求,产品的表面一定要光滑,产品几处要与其它产品配合的地方精度要高,配合后不能要有松动或过紧的现象,操作部等手能直接接触的部位不能有飞边,机盖底侧又加之存在着18处侧槽或侧钩,此可见该产品有别于一般产品,在本次设计中采用了斜顶机构大大减少了模具的加工难度、成本、以及日后的许多附属问题。在未来几年,该技术将被广泛应用于各种带有侧槽或侧钩等的注塑模具中。