深孔内圆磨床磨头设计

无需注册登录,支付后按照提示操作即可获取该资料.

摘 要

深孔内圆加工是目前加工行业中的一大难点,特别是深孔内圆的精加工。由于其孔径小,运用传统的砂轮磨削时将对要求砂轮的直径更小、转速更高从而难以实现;由于其孔深,对主轴的刚度提出了更高的要求。随着砂带磨削技术的兴起和发展,砂带磨削深孔内圆已经成为了深孔内圆精加工的首选方法。砂带磨削是根据工件形状,以相应的接触方式,利用高速运动的砂带对工件表面进行磨削、研磨和抛光的一种新型高效磨抛工艺。其具有系统震动小、稳定性好、被加工表面质量高、成本低、操作简便、安全卫生等优点。本文作者从深孔内圆加工出发,结合砂带磨削的原理机理及特点等,提出了运用砂带磨削深孔内圆的新方法。作者根据实际情况,设计出了一款用于磨削深孔内圆的砂带磨床,并对其中关键零件进行了校核。

关键词:深孔内圆加工 砂带磨削 磨床 设计

ABSTRACT

The deeply hole internal cylindrical work is in a present processing profession ig difficulty, specially deep hole internal bore precision work. Because its aperture is small, when utilization tradition grinding wheel grinding to will request grinding wheel's diameter to be smaller, the rotational speed to be higher, thus realizes with difficulty. As a result of its depth of hole, set a higher request to main axle's rigidity. And develops along with belt grinding technology's starting, the belt grinding deep hole internal bore had already become the deep hole internal bore precision work first choice method. The belt grinding is according to the work piece shape, by the corresponding contact way, the use high speed movement's emery tape carries on the grinding, the attrition and the polishing one kind to the work piece surface new rubs highly effective throws the craft. It has the system to vibrate, the stability merits and so on good, to process slightly the surface quality to be high, the cost is low, operation simple, safety and health. This article author embarks from the deep hole internal work, the union belt grinding's principle mechanism and the characteristic and so on, proposed the utilization belt grinding deep hole internal bore new method. The author acts according to the actual situation, designed one section to use in the grinding deep hole internal bore the belt sander, and to the crucial element has carried on the examination.

Key words: Deeply hole internal cylindrical work, Belt grinding, Grinding machine, Design.

本课题的研究内容

本课题主要针对很难对深孔内壁磨削加工的现状,结合砂带磨削的加工特性,提出采用砂带磨削深孔内圆的方案,进行深孔内圆磨床磨头设计。

系统调研和分析国内外砂带磨削的研究、发展和应用情况;理解和掌握深孔内圆的加工工艺要求,进行深孔内圆磨头的功能分析;结合实际问题研究,对深孔内圆磨床磨头进行概念设计;对磨头设计相关参数进行选择并完成相应计算;并绘制了深孔内圆磨床磨头的装配图及零件图。

目 录 20000字

摘 要 1

ABSTRACT 2

1 绪 论 5

1.1 深孔内圆加工问题 5

1.2 深孔内圆砂带磨削的国内外现状 7

1.3 本课题的研究内容 7

2 砂带磨削原理 9

2.1砂带磨削的原理 9

2.2砂带的磨削机理 9

2.3砂带磨削与砂轮磨削的比较 10

2.4砂带磨削的分类 12

2.5砂带磨削的特点 12

2.6砂带磨削的发展和应用 14

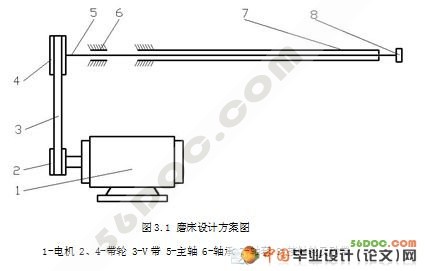

3 总体方案分析 16

4 深孔内圆磨削机床组件设计 17

4.1 电机的选用 17

4.2 传动方式的确定及设计 18

4.2.1、传动形式的比较和选取 18

4.2.2、传动参数的确定 20

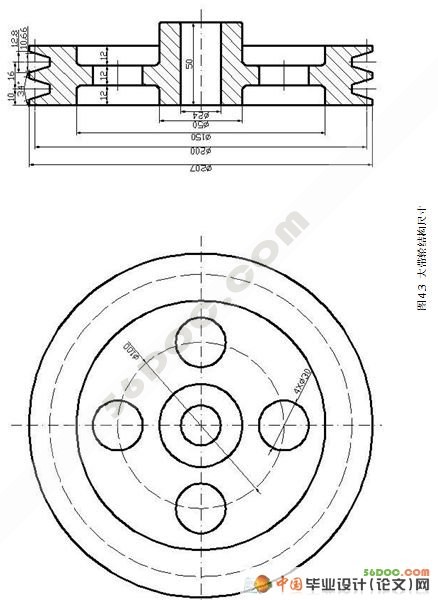

4.2.3、V带轮结构的设计 24

4.3 主轴的设计 28

4.4 轴承、键的选用 32

5 磨头功能部件设计 33

5.1 尺寸关系确定 33

5.2 接触轮的设计 33

5.3 张紧机构的设计 34

5.4 调偏装置的设计 34

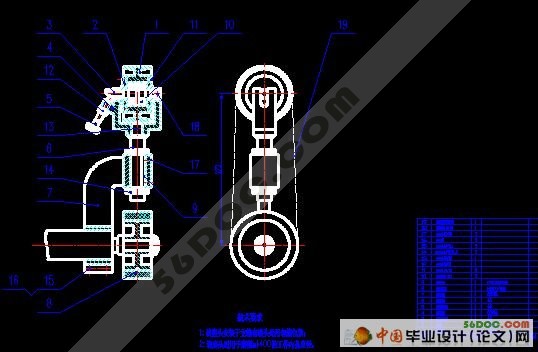

5.5 磨头结构图 34

6 关键零件的校核 36

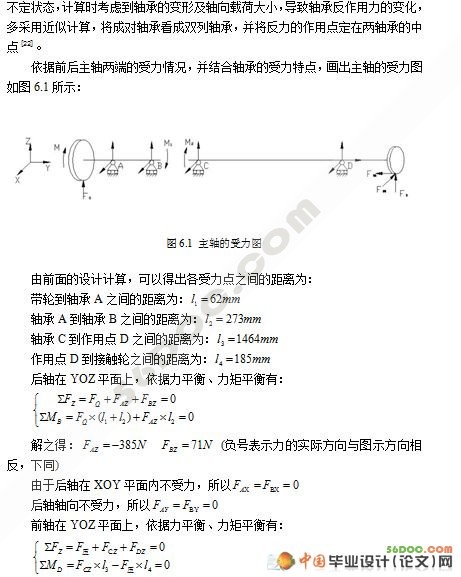

6.1 主轴的校核 36

6.1.1、扭矩计算 36

6.1.2、受力计算 36

6.1.3、弯矩计算 38

6.1.4、安全系数校核 38

6.2 键的安全校核 40

7 总结 42

致 谢 43

参 考 文 献 44