黄沙坪铅锌矿3250t/d选矿厂设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

黄沙坪铅锌矿3250t/d选矿厂设计(含CAD图)(任务书,开题报告,论文说明书9000字,CAD图7张)

摘 要

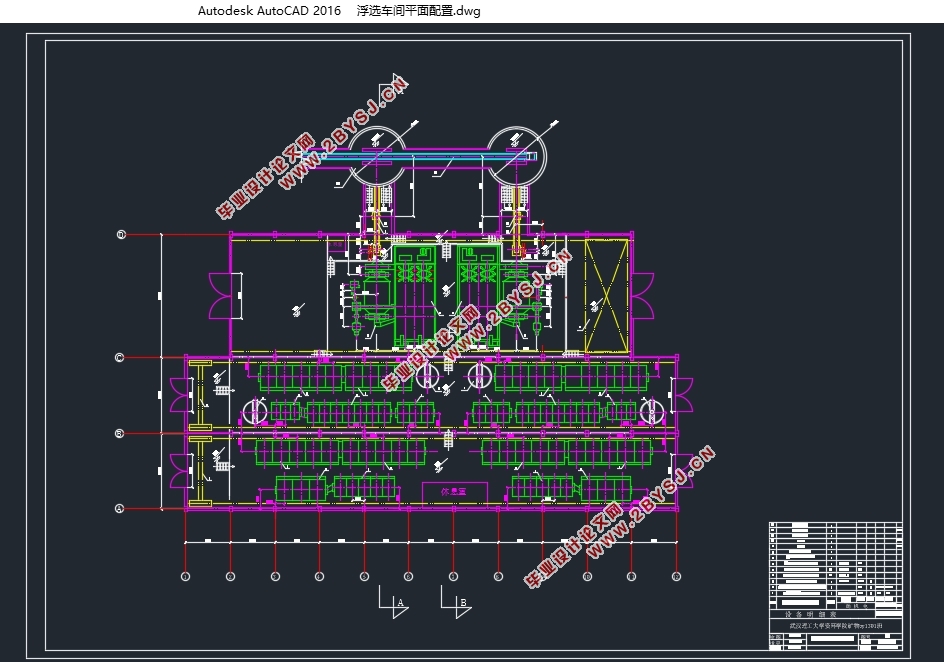

按照毕业设计任务书的要求,设计了黄沙坪铅锌矿3250t/d选矿厂,产品为铅精矿和锌精矿。在查阅了相关的资料之后,确定了相应的工作制度,再仔细地分析后确定了工艺流程,即:破碎采用三段一闭路流程,磨矿采用一段闭路流程,浮选采用全优先浮选工艺,精矿采用先浓缩后过滤的两段脱水。对设计工艺流程进行了工艺指标计算,包括破碎、筛分、磨矿、浮选(包括矿浆流程)和脱水流程。对破碎、筛分、磨矿、分级、浮选及脱水设备进行了选择计算和方案比较,确定了工艺所需的工艺设备。进行了厂房总体布置,并进行了厂房内的设备配置。根据选厂房的地形条件,沿山坡地布置,其中,粗碎、中细碎、筛分厂房分开布置,粗碎、中细碎及筛分车间平行等高线配置。磨矿浮选共厂房配置,其中磨矿采用纵向配置,浮选机采用横向配置。浓缩机配置在露天,过滤机与精矿仓配置在厂房内。完成了粗碎、中细碎、筛分、磨浮、数质量及矿浆流程图和设备联系图共7张。

关键词:选矿厂设计 铅锌矿 浮选 黄砂坪

Abstract

In accordance with the requirements of the graduation design task book, designed flotation 3250 tons / day Huangshaping lead-zinc ore concentrator, the product is lead concentrate and zinc concentrate

In the collection of data, The work institutions of each works were determined, and the technological process was also chosed and reasoned The process of crushing is three sections with half open circuit, the grinding process is one section with closed circuit, the floation process is selective flotation of lead minerals, and a process with two sections dewatering circiut which included concentration and filtion was adopted .

parameters of crushing,screening,grinding ,floation(include the circuit of pulp)and dewatering were computed, respectively. Then the technological parameters of equipments were computed and the schemes of equipments were compared and the optimal equipments were determined.

The general arrangement of concentrator plant and the allocation of equipments in diferent works hop were presented. According to the topography of plant site, plants were arranged along the slope of mountain. The works hops of coarse crushing, middle and fine crushing and screening were aloted independent. Arrangment with parallel contour line of coarse crushing works hop、 middle and fine crushing and screening works hops were used. The works hops of grinding and flotation were put togather, and the longitudinal and lateral plans were used for the mills and flotation machines respectively. Concentrator arranged in the open air, filter and concentrate warehouse configuration in the factory. Completed a coarse crushing, in the crushing, screening, grinding, the number of quality and pulp flow chart and equipment linked to a total of 7 photos

Keywords: concentrator design, lead and zinc ores, flotation , HuangShaPing

目 录

目录 i

摘 要 iii

Abstract iv

第1章 绪论 1

1.1 建厂地区概况 1

1.2 选厂厂址基本特点 2

1.2.1 厂址选择 2

1.2.2 供电和供水 3

1.2.3 尾矿输送与处理 3

1.2.4 原矿和精矿产品运输 3

1.3 采矿基本情况 4

1.4 选矿设计指标和产品 4

1.5 其它情况 5

第2章 设计流程论述 6

2.1 矿床性质 6

2.2 原矿性质 6

2.2.1 岩矿鉴定 6

2.2.2 原矿化学分析和物相分析 7

2.2.3 原矿基本物理性质 8

2.3 流程论述 9

2.3.1 破碎流程论述 9

2.3.2 磨矿流程论述 11

2.3.3 选别流程论述 12

2.3.4 脱水流程论述 18

2.3.5 设计的工艺流程 19

第3章 车间工作制度和生产能力 20

3.1 车间工作制度 20

3.2 车间生产能力 20

第4章 工艺流程和工艺设备 21

4.1 破碎流程和破碎设备的选择与计算 21

4.1.1 破碎流程计算 21

4.1.2 破碎设备选择和计算 24

4.1.3 筛分设备的选择与计算 29

4.2 磨矿流程计算 30

4.3 浮选流程计算 31

4.4 矿浆流程计算 43

4.4.1 磨矿流程 43

4.4.2 选别流程。 44

4.5 磨矿、分级设备选择与计算 49

4.5.1 磨矿机计算。 49

4.5.2 螺旋分级机计算 53

4.6 浮选机的选择与计算。 54

4.6.1 浮选矿浆体积计算 54

4.6.2 浮选机槽数计算 55

4.6.3 搅拌槽的选择和计算 58

4.7 脱水设备选择和计算 60

4.8 过滤机选择与计算 60

4.9 辅助设备的计算 62

4.9.1 矿仓 62

4.9.2 胶带机的选择与计算 65

4.9.3 其他辅助设备的选择与计算 69

第5章 总体布置与设备配置 73

5.1 厂房的总体布置 73

5.2 厂内设备配置 74

5.2.1 破碎厂房的设备配置 74

5.2.2 磨浮车间设备配置 74

5.2.3 脱水车间设备配置 75

5.3 设计图纸目录 75

结 语 76

参考文献 77

附一 设备选择计算附表 78